Clamping tool equipment for cylindrical part cutting processing

A cutting and fixture technology, which is applied in the field of fixture equipment for cutting cylindrical parts, and can solve problems such as inability to process workpieces alone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features and or steps.

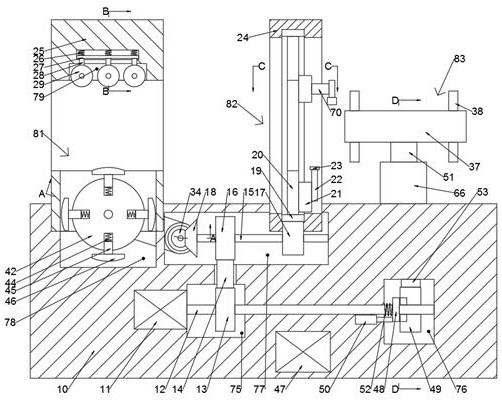

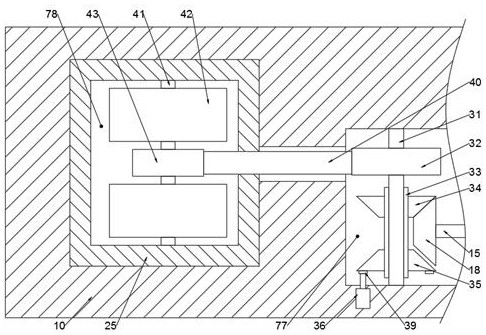

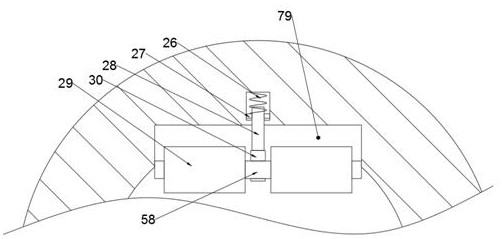

[0016] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] A fixture device for cutting cylindrical parts of the device of the present invention includes a body 10, a transmission chamber 75 is provided in the body 10, a clamping chamber 77 is provided on the upper side of the transmission chamber 75, and a clamping chamber 77 is provided on the right side of the body 10. There is an engaging cavity 76, the upper side of the body 10 is fixed with a fixed body 25 and a fixed ring 24, the lower side of the fixed body 25 is provided with a moving cavity 78, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com