High-strength and high-toughness basic magnesium sulfate fiber concrete and preparation method thereof

A magnesium sulfate fiber and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reduced fluidity, poor strength and economical efficiency, and lack of concrete, and achieve good durability and strength and the effect of improving toughness and dispersing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation:

[0019] (1) Take by weight 377 parts of light-burned magnesia (water-cement ratio 0.53, light-burned magnesia active content is 65.52%), 129 parts of magnesium sulfate heptahydrate, 600 parts of sand and 1110 parts of crushed stone, pre-dried Stir until all are delivered to the inside of the mixer;

[0020] (2) take by weight 4.6 parts of citric acid and 176 parts of water, fully dissolve;

[0021] (3) Put 60-70% of the solution obtained in step (2) into the mixer for stirring, first stir for 30s, after the volume of the mixture decreases when it meets water, then add the remaining solution into the mixer, and continue stirring for 150s to obtain . The test results are shown in Table 1.

Embodiment 2

[0023] Preparation:

[0024] (1) Take by weight 377 parts of light-burned magnesia (water-cement ratio 0.53, light-burned magnesia active content is 65.52%), 129 parts of magnesium sulfate heptahydrate, 600 parts of sand and 1110 parts of gravel, wherein Stones are continuously graded from 5 to 20mm, dry mixed in advance, until all are transported to the inside of the mixer;

[0025] (2) Take by weight 4.6 parts of citric acid and 176 parts of water, add 0.49 parts of UPE fibers and 0.65 parts of PVA fibers after fully dissolving, the length of both fibers is 12mm, and mix uniformly;

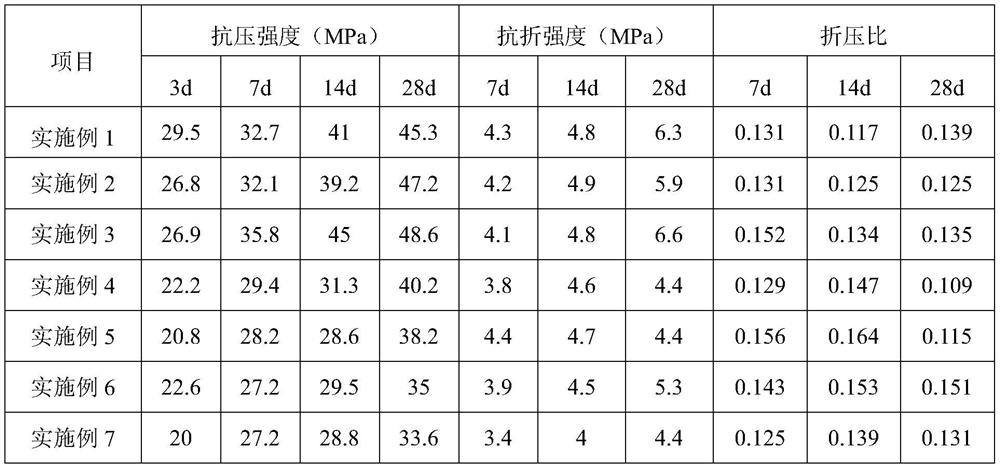

[0026] (3) Put 60-70% of the mixture obtained in step (2) into the blender and stir for 30s first, after the volume of the mixture decreases when it meets water, add the rest of the mixture into the blender and continue stirring for 150s to obtain . The test results are shown in Table 1.

Embodiment 3

[0028] Preparation:

[0029] (1) Take by weight 377 parts of light-burned magnesia (water-cement ratio 0.53, light-burned magnesia active content is 65.52%), 129 parts of magnesium sulfate heptahydrate, 600 parts of medium sand and 1110 parts of gravel, wherein The crushed stones are continuously graded from 5 to 20 mm, and dry-mixed in advance until all of them are transported into the mixer;

[0030] (2) Take by weight 4.6 parts of citric acid and 176 parts of water, add 0.97 parts of UPE fiber and 1.3 parts of PVA fiber after fully dissolving, two kinds of fiber lengths are 12mm, mix uniformly;

[0031] Step (3) is the same as step (3) in Example 2. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com