Segmented prestressed concrete-filled steel tube truss continuous combined bridge and construction method thereof

A steel tube concrete and prestressing technology, which is applied in truss bridges, erection/assembly bridges, bridges, etc., can solve problems such as bridge decks being prone to tensile cracking, improve long-term service performance and durability, delay cracking, and compressive performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

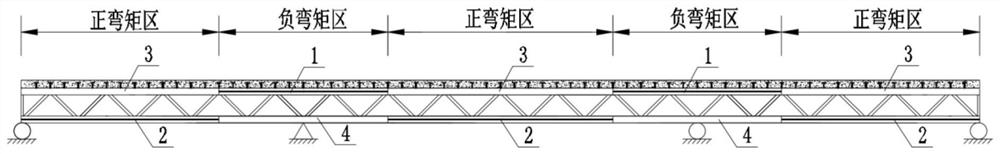

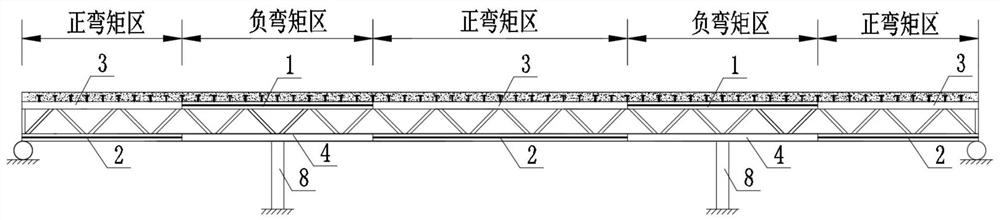

[0029] The segmental prestressed steel pipe concrete continuous composite girder bridge or composite rigid frame bridge provided by the present invention comprises a prestressed steel pipe concrete upper chord 1, a prestressed steel pipe concrete lower chord 2, an ordinary steel pipe concrete upper chord 3, and an ordinary steel pipe concrete lower chord 4. Steel pipe webs 5 and rigid frame pier columns 8, such as figure 1 with figure 2 shown.

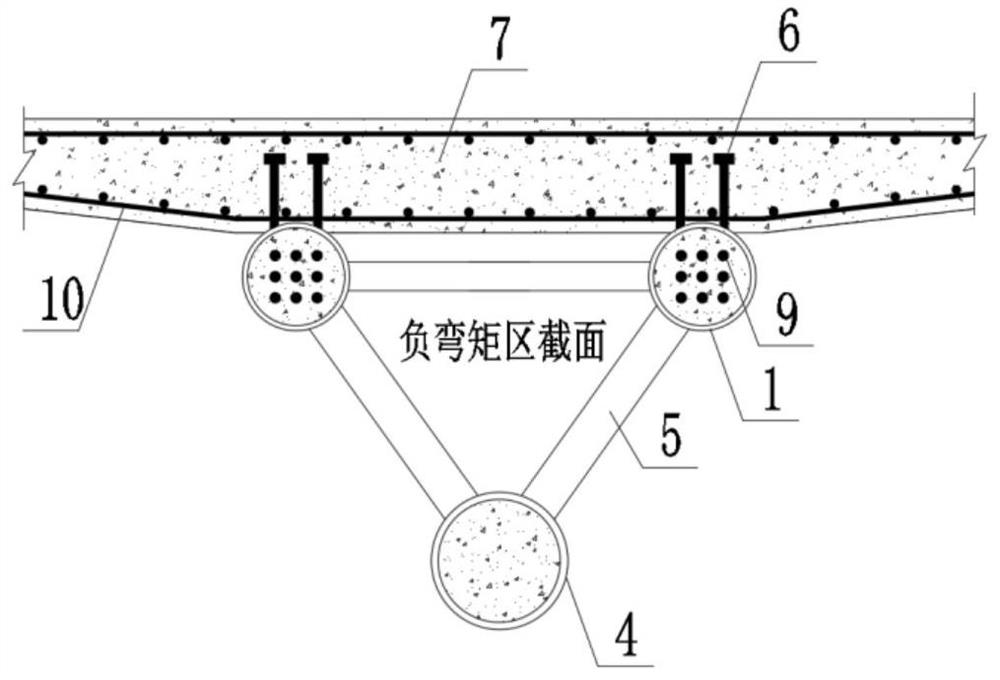

[0030] In order to ensure the combined effect of the CFST truss and the concrete bridge deck, a connector with shear and pull resistance is welded above the prestressed CFST top chord 1 and the ordinary CFST top chord 3, and the connectors can be connected by studs for shear resistance Item 6, such as image 3 with Figure 4 shown. A certain number of stressed steel bars and structural steel bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com