Slope surface debris flow prevention and treatment engineering structure and slope surface debris flow prevention and treatment method

A technology for prevention and control of engineering and debris flow, applied in drainage structures, waterway systems, buildings, etc., can solve the problems of large amount of engineering investment, difficult prevention and blocking engineering, and high investment cost, achieve low investment quota, reduce the amount of infiltration water, and is not easy. The effect of soil sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

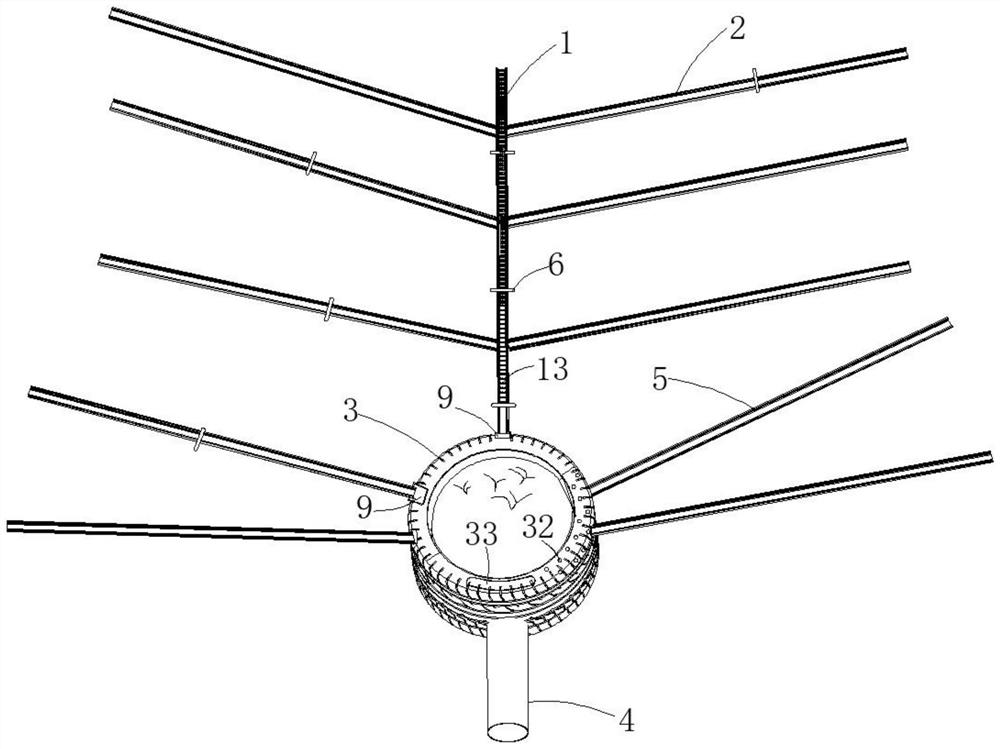

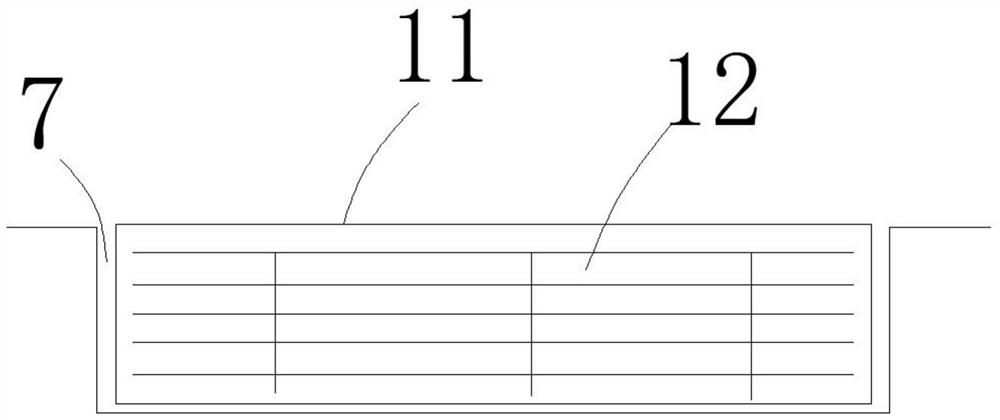

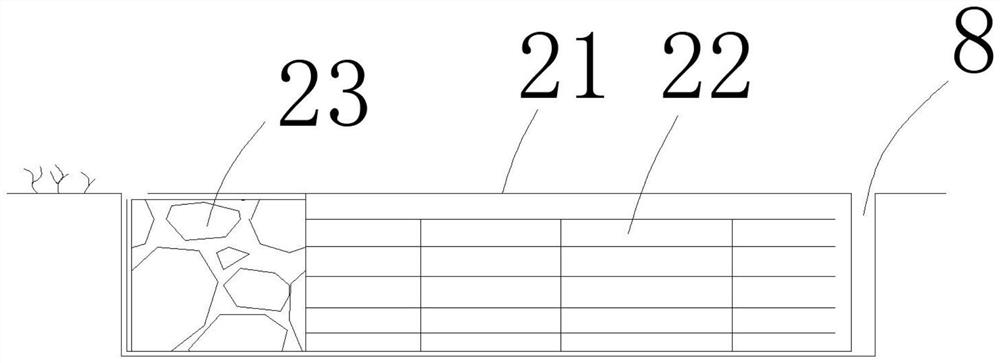

[0058] The slope debris flow prevention and control engineering structure in this embodiment adopts the method of intercepting runoff and diverting the source to reduce the amount of infiltration water in areas prone to debris flow to a certain extent, so as to achieve the purpose of preventing debris flow disasters caused by soil layer sliding, such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0059] Basically, a group of the slope debris flow prevention and control engineering structure includes a main diversion zone 1 , at least one first branch diversion zone 2 , a hydrosphere well 3 and a drainage pipe 4 .

[0060] In this slope debris flow prevention engineering structure, the main diversion zone 1 is arranged vertically, and the first diversion zone 2 is arranged obliquely. The first diversion zone 2 can be set in multiples according to the actual situation. It can be set on the left or right side of the main guide belt 1. The main diversion belt 1 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com