Fiber feeder and feeding method for concrete mixing station

A feeder and mixing plant technology, applied in the fiber feeder and feeding field of concrete mixing plant, can solve problems such as damage to the health of workers, poor control of the amount of addition, and reduction of concrete quality, so as to ensure occupational health, The effect of production quality assurance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

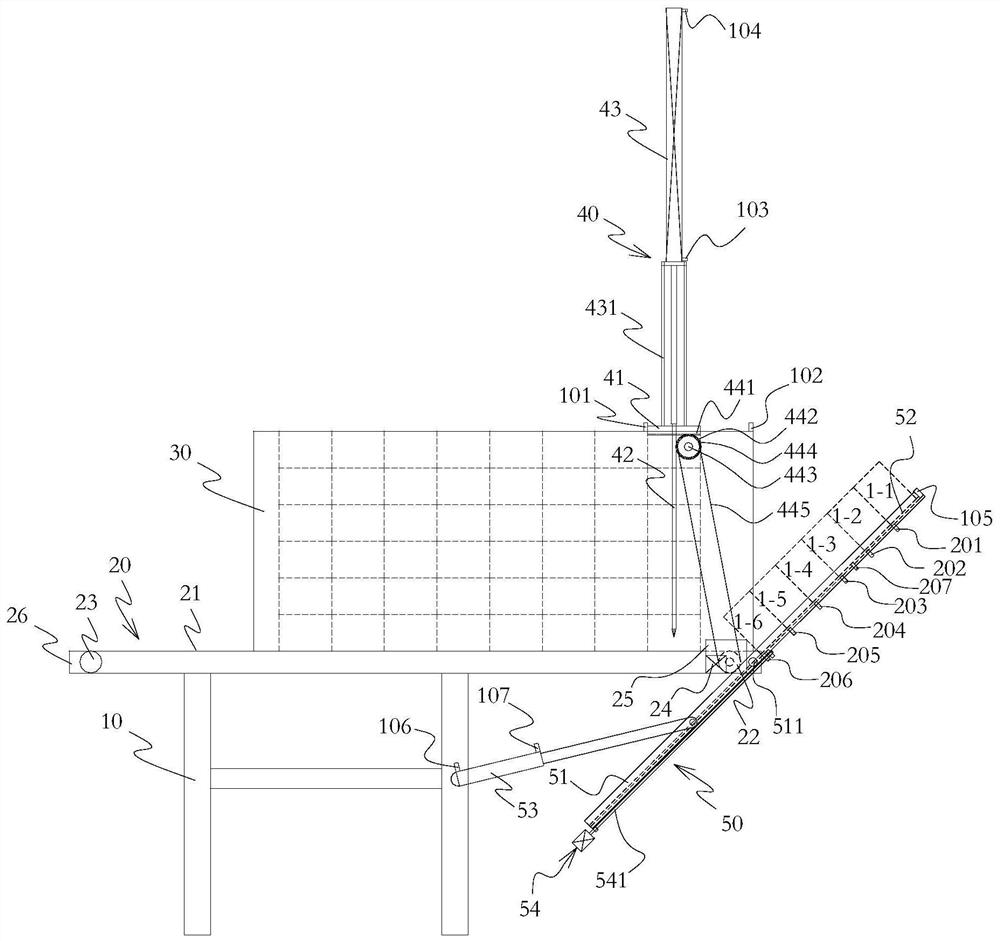

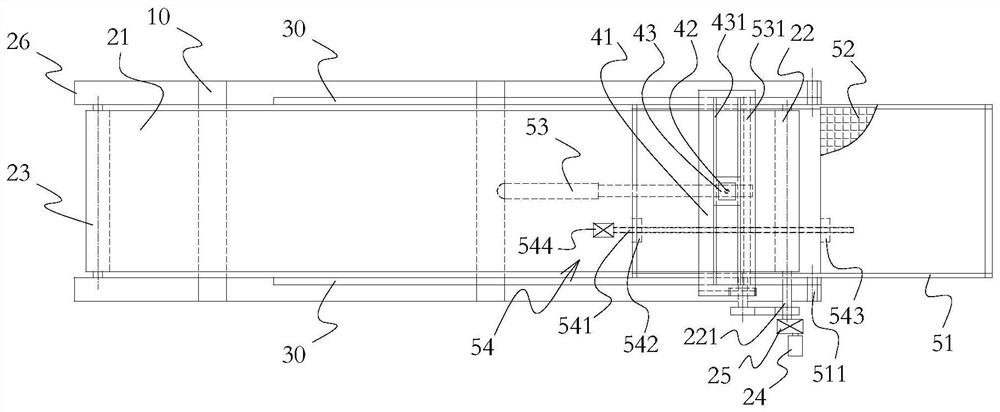

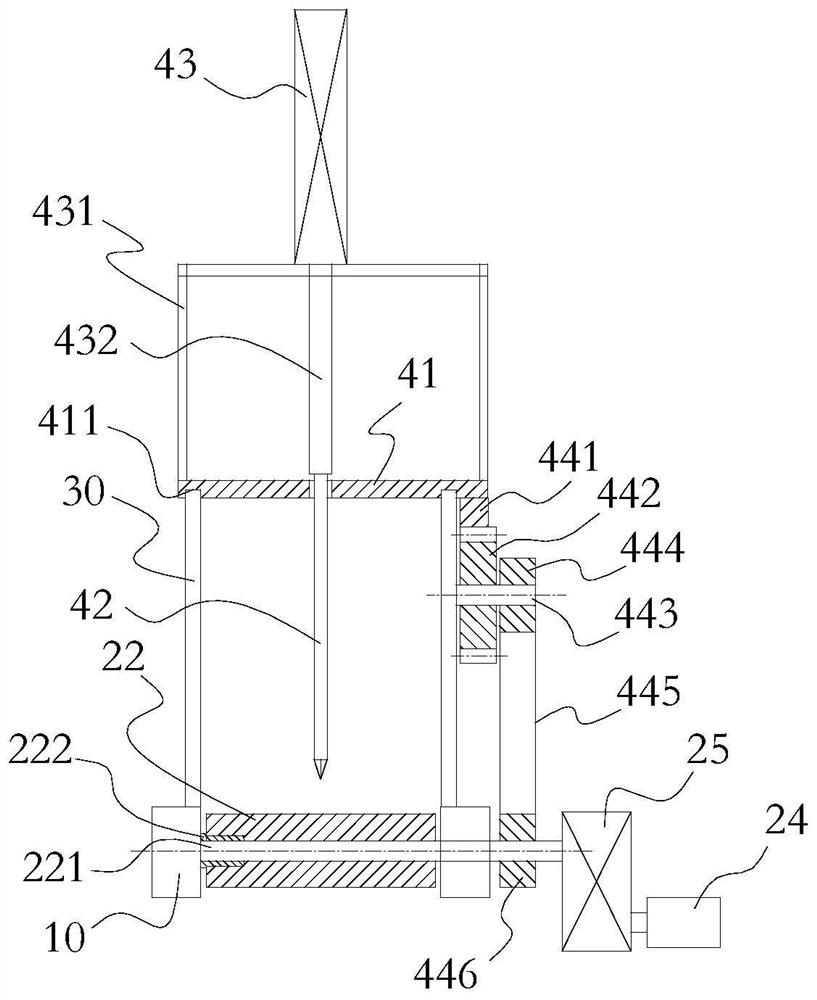

[0048] refer to Figure 1 to Figure 4 , The present embodiment provides a fiber feeder for a concrete mixing plant, including: a frame 10 , a belt conveyor 20 , a baffle plate 30 , a sliding positioning mechanism 40 and a feeding mechanism 50 .

[0049] The frame 10 is a rectangular frame welded by section steel, used to support the feeder and install various parts, including four supporting legs and a horizontal mounting surface supported by the four supporting legs.

[0050] The belt conveyor is mainly composed of a conveyor belt 21, a conveyor belt drive roller 22, a driven roller 23, a conveyor belt drive motor 24, a reducer 25 and a frame 26. The belt conveyor 20 is installed on the mounting surface of the top of the frame 10 through its frame 26 inclined from back to front, and its inclination angle is about 10°~15°. Adopting such a design scheme can make the fiber package on the one hand in the charging and When moving, it is inclined to the front side with the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com