Method of purifying 6-gingerol

A technology of gingerol and ginger oleoresin, which is applied in the field of purification, can solve the problems of severe product dilution, low operation repeatability, and unsuitability for industrial production, and achieve stable operation and low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

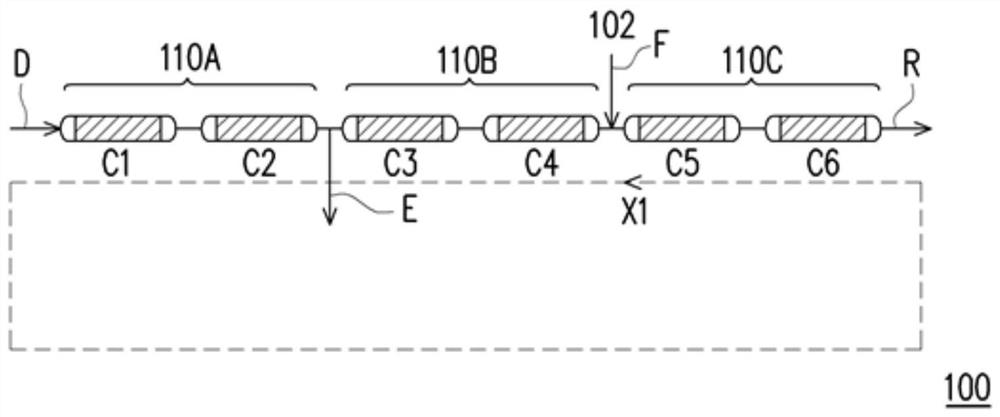

Method used

Image

Examples

experiment example 1

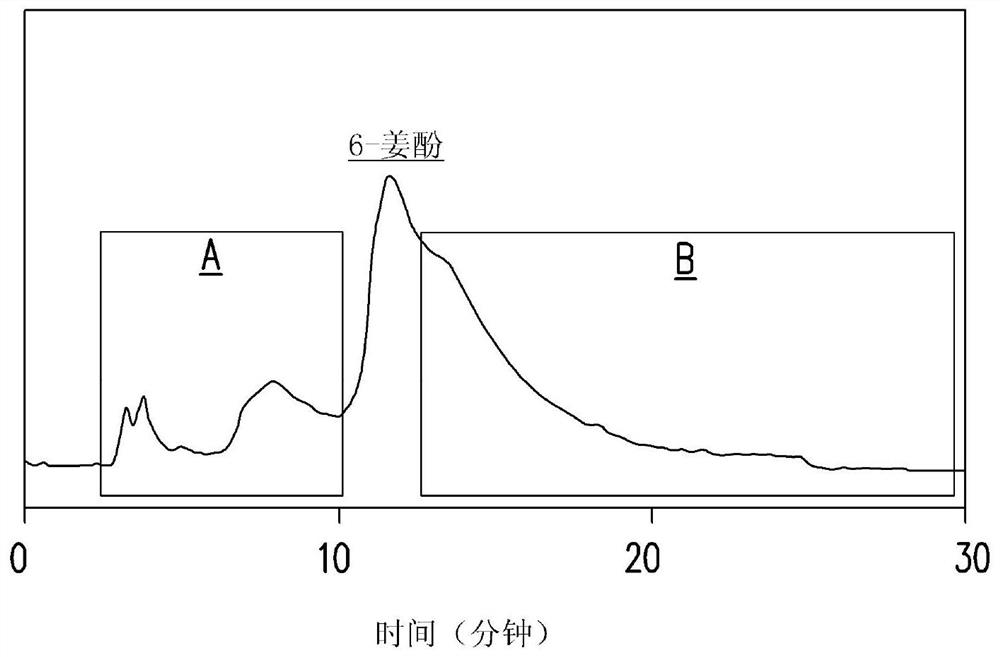

[0068] [Single string test]

[0069] In order to set the operating conditions of simulated moving bed chromatography, before the actual separation of 6-gingerol, a suitable supercritical fluid chromatography system was screened out, and the retention behavior of 6-gingerol and other major impurities was investigated. In Experimental Example 1, ginger oleoresin was used as an analysis sample, and analyzed by the above analysis method using a high performance liquid chromatography ultraviolet detector (HPLC / UV). The stationary phase is random silica, and the mobile phase is supercritical carbon dioxide washing agent with isopropanol as auxiliary solvent. Among them, random silica as a stationary phase is filled in a packed column of 1 cm ID × 25 cm L, and supercritical fluid equipment is connected in series. The operation condition of supercritical fluid equipment is set as pressure 150bar, and temperature is 50 ℃, and carbon dioxide flow rate is set as 4.0 g / min, isopropanol f...

experiment example 2

[0092] [Single string test]

[0093] In the single-column test of Experimental Example 2, ginger oleoresin was used as an analysis sample, and analyzed by the above analysis method using a high performance liquid chromatography ultraviolet detector (HPLC / UV). The stationary phase is a preparative-grade surface-modified silica filler, and the mobile phase is a supercritical carbon dioxide flushing agent with isopropanol as an auxiliary solvent. Among them, the preparative-grade surface-modified silica filler used as the stationary phase is filled in a 1cm ID×25cm L packed column and then connected in series with supercritical fluid equipment. The operation condition of supercritical fluid equipment is set as pressure 140bar, 50 ℃ of temperature, carbon dioxide flow rate is set as 4.0 g / min, isopropanol flow rate is 0.898 milliliter / min (mass percentage is about 15wt%), under this condition super critical fluid density ρ SF = 0.724 g / mL.

[0094] Figure 6 Chromatograms obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com