Cationic nitrile cross-linking reaction and method for preparing polyelectrolyte membrane

A technology of cross-linking reaction and polyelectrolyte, which is applied in the field of cationic nitrile cross-linking reaction and preparation of polyelectrolyte membrane, and achieves good stability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

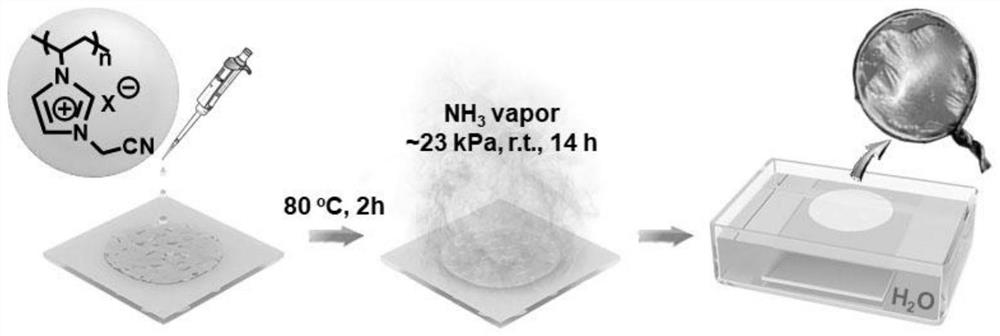

[0052] The synthetic method of triazine compound among the present invention comprises the following steps:

[0053] (1) Dissolve polyvinyl acetonitrile pyridinium cationic bromide in DMSO solvent, and prepare a 0.5wt‰ casting solution.

[0054] (2) Put the prepared 400 μL polyvinyl acetonitrile pyridinium cationic bromide casting solution drop by drop on the glass slide, and put it in an oven at 80°C for 2 hours.

[0055] (3) The dried glass sheet is placed in an ammonia gas atmosphere formed by 0.2 wt% ammonia water at 10° C., and sealed for 8 hours.

[0056] (4) Take out the glass sheet, place it in a watch glass filled with clear water, press down on a corner of the glass sheet slightly, and the film will be separated from the glass bottom sheet to obtain an ultra-thin film with a film thickness of about 19nm.

Embodiment 2

[0058] The synthetic method of triazine compound among the present invention comprises the following steps:

[0059] (1) Dissolve polyvinyl acetonitrile pyridinium cationic bromide in DMSO solvent, and prepare a 0.5wt‰ casting solution.

[0060] (2) Put the prepared 400 μL polyvinyl acetonitrile pyridinium cationic bromide casting solution drop by drop on the glass slide, and put it in an oven at 80°C for 2 hours.

[0061] (3) The dried glass sheet is placed in an ammonia gas atmosphere formed by 0.2 wt% ammonia water at 50° C., and sealed for 8 hours.

[0062] (4) Take out the glass sheet, place it in a watch glass filled with clear water, press down on a corner of the glass sheet slightly, and the film will be separated from the glass bottom sheet to obtain an ultra-thin film with a film thickness of about 21nm.

Embodiment 3

[0064] The synthetic method of triazine compound among the present invention comprises the following steps:

[0065] (1) Dissolve polyvinyl acetonitrile pyridinium cationic bromide in DMSO solvent, and prepare a 0.5wt‰ casting solution.

[0066] (2) Put the prepared 400 μL polyvinyl acetonitrile pyridinium cationic bromide casting solution drop by drop on the glass slide, and put it in an oven at 80°C for 2 hours.

[0067] (3) The dried glass sheet is placed in an ammonia gas atmosphere formed by 14wt% ammonia water at 50° C., and sealed for 8 hours.

[0068] (4) Take out the glass sheet, place it in a watch glass filled with clear water, press down on a corner of the glass sheet slightly, and the film will be separated from the glass bottom sheet to obtain an ultra-thin film with a film thickness of about 22nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com