Method for regulating phase proportion of TC4 titanium alloy through heat treatment

A titanium alloy and phase ratio technology is applied in the field of regulating the phase ratio of TC4 titanium alloy through heat treatment, which can solve the problems of insufficient coordination and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for regulating the phase ratio of TC4 titanium alloy by heat treatment, according to the following steps:

[0040] Step 1: Sandpaper the TC4 titanium alloy to remove the oxide layer on its surface, so as to prevent the oxide layer on the surface from interfering with the heat treatment effect during the subsequent heat treatment process;

[0041] Step 2: Put the polished TC4 titanium alloy into the box-type resistance furnace after the furnace temperature reaches the set temperature, and adopt the α phase phase transition temperature T α Under normalizing treatment for 4h.

[0042] The surface of the TC4 sample after heat treatment is polished, mechanically polished, and metallographically corroded in sequence, and then the metallographic structure of the corroded surface is observed, and the colored α phase in the metallographic diagram is statistically analyzed by image pro plus software. It was confirmed that the proportion of the α phase in the heat-treate...

Embodiment 2

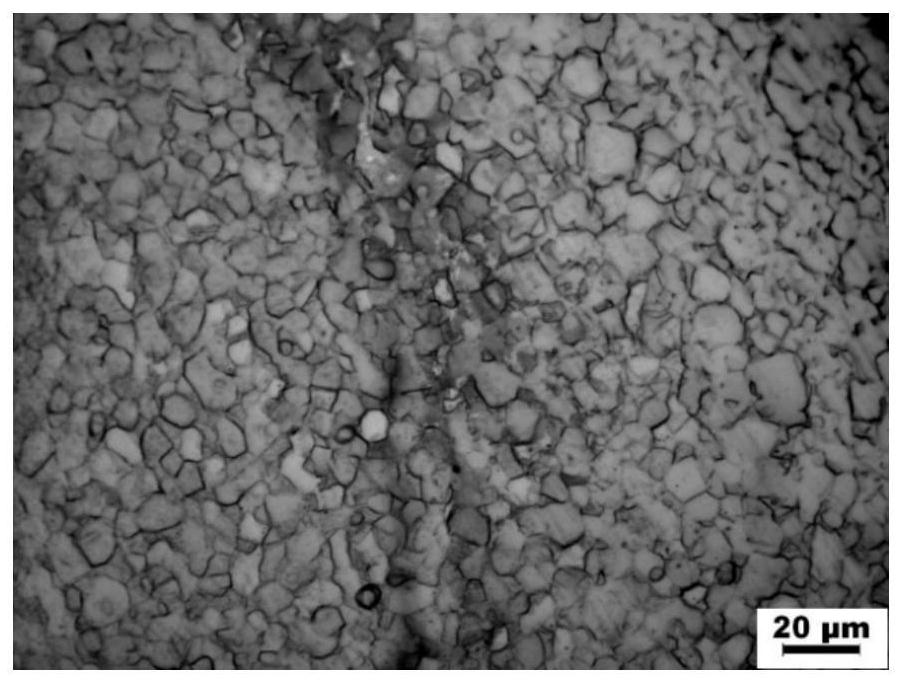

[0044] The present embodiment operation step is the same as embodiment 1, wherein, adopt (T to TC4 titanium alloy) α The normalizing treatment mode was carried out for 4h at +30)°C to obtain a TC4 titanium alloy with a phase ratio of 77.3% and a phase ratio of β of 22.7%. The metallographic microstructure of the TC4 titanium alloy obtained by heat treatment is as follows image 3 As shown, the α phase (white) of the metallographic microstructure is colored and the proportion of the α phase is counted Figure 4 shown.

Embodiment 3

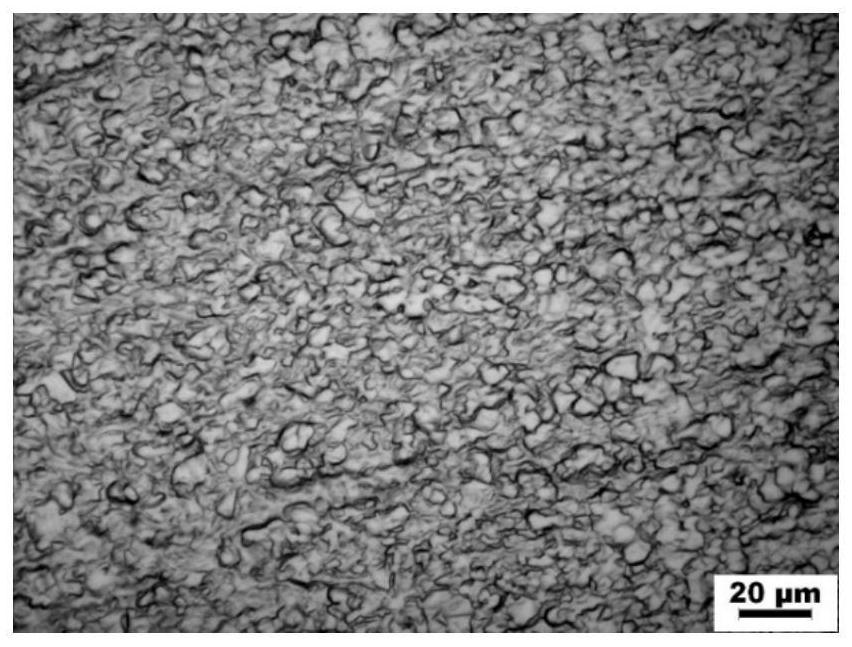

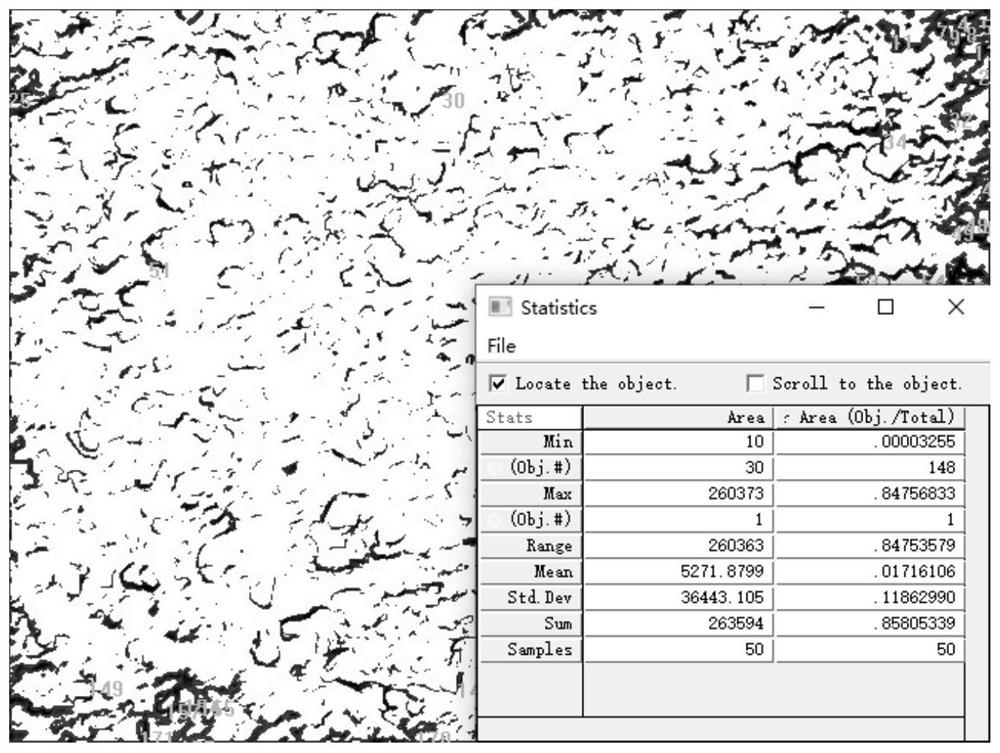

[0046] The operation steps of this embodiment are the same as those in Embodiment 1, wherein the β phase transition temperature T is adopted for the TC4 titanium alloy β Under the normalizing treatment mode for 2h, the TC4 titanium alloy with α phase ratio of 52.7% and β phase ratio of 47.3% was obtained. The metallographic microstructure of the TC4 titanium alloy obtained by heat treatment is as follows Figure 5As shown, the α phase (white) of the metallographic microstructure is colored and the proportion of the α phase is counted Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com