Ultrafast laser pulse width measuring device and control method thereof

A pulse width, ultrafast laser technology, applied in the field of laser applications, can solve problems such as large insertion loss, cumbersome operation, and reduced laser spot quality, and achieve the effects of low structural cost, easy operation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

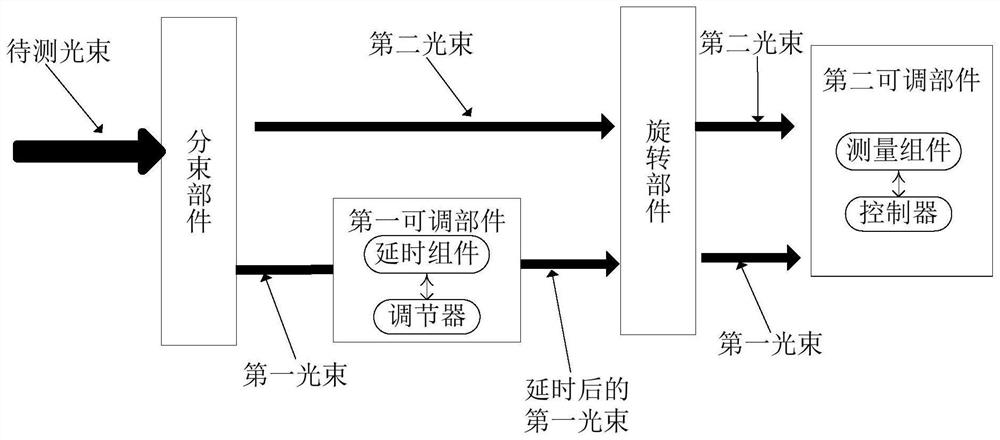

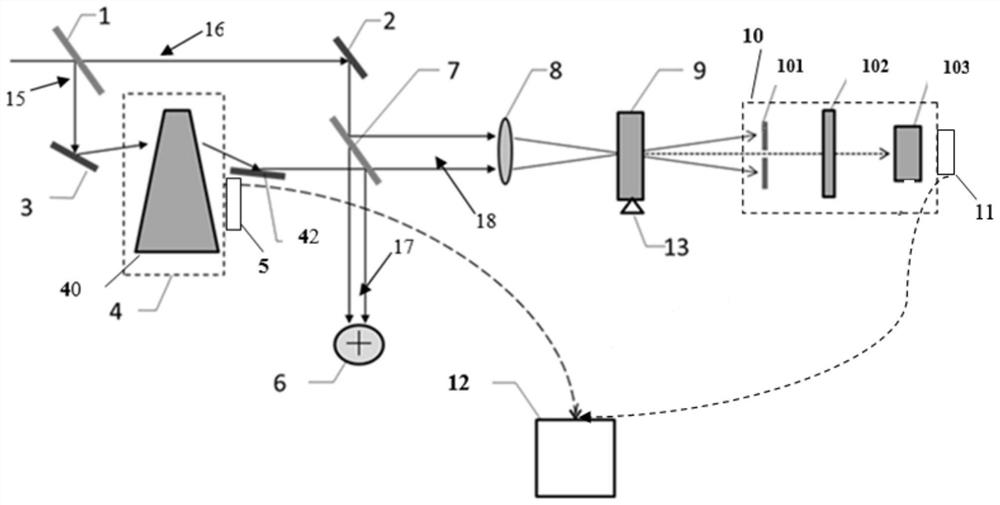

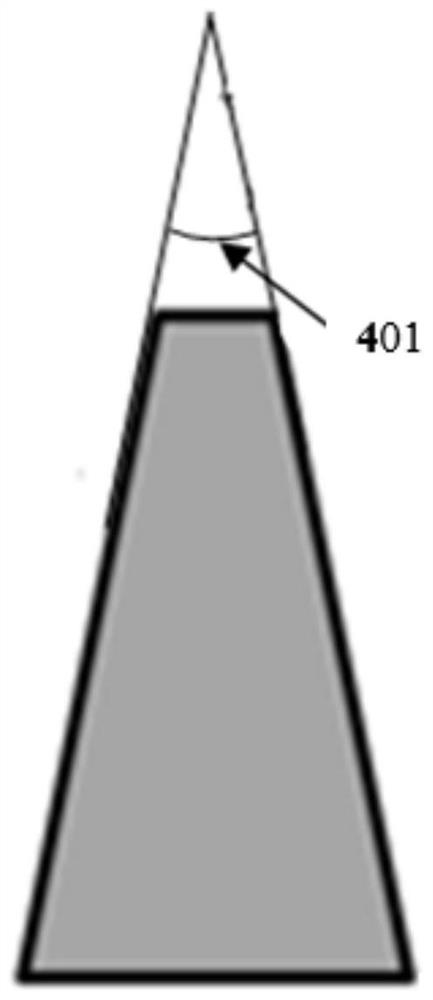

[0053] refer to Figure 2 to Figure 3 , the present embodiment improves a schematic diagram of an optical path of an ultrafast laser pulse width measuring device, including a beam splitting component, a first adjustable component 4, a lens 8, a rotating component, a second adjustable component 10, an optical path calibration component 6, and a processor 12 , wherein the beam splitting component includes a beam splitting mirror 1, a mirror 2, a mirror 3 and a beam splitting mirror 7, and the first adjustable component 4 includes a wedge prism 40 (facet angle 401 is less than 30°), a mirror 402, a first The adjustable base and regulator 5, the wedge prism 40 and the reflector 402 form a delayer placed on the first adjustable base, and the first adjustable base is connected to the controller 5, the beam splitter 1 and the reflector 3 are placed On the light incident side of the first adjustable component 4, the beam splitter 7 and reflector 2 are placed on the light output side o...

Embodiment 2

[0060] Such as Figure 4As shown, a schematic diagram of the optical path of an ultrafast laser pulse width measurement device improved in this embodiment, including a beam splitting component, a first adjustable component 4, an optical path calibration component 6, a lens 8, a rotating component, and a second adjustable component 10 And processor 12; The beam splitting part comprises beam splitter 1, reflector 2, reflector 3 and beam splitter 7, and the first adjustable component 4 comprises reflector 41, reflector 42, reflector 43, reflector 44, The regulator 5 and the first adjustable base, wherein the reflector 41, the reflector 42, the reflector 43 and the reflector 44 form a quadrilateral to form a time delayer, and the reflector 42 and the reflector 43 are placed on the first adjustable base , the adjuster 5 is connected with the first adjustable base; the rotating part comprises a barium metaphosphate crystal 9 (BBO crystal) and a rotating bracket 13 and the barium met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com