Quartz tuning fork resonant temperature and humidity sensor

A humidity sensor and temperature sensor technology, applied in the field of sensors, can solve problems such as poor interchangeability, loss of measurement accuracy, and decreased sensitivity, and achieve the effects of reducing production costs, improving stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

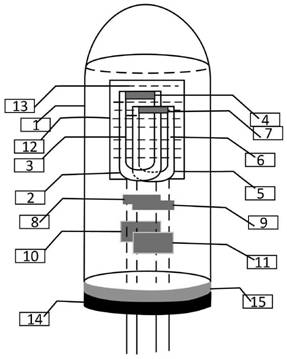

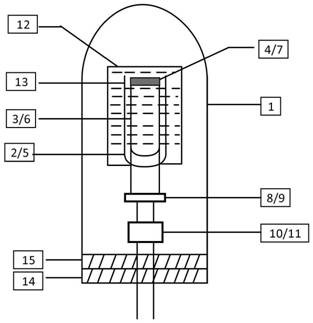

[0017] In order to enable those skilled in the art to better understand the technical solution of the patent of the present invention, the technical solution of the patent of the present invention is clearly and completely described below in conjunction with the accompanying drawings of the patent of the present invention.

[0018] A quartz tuning fork resonant temperature and humidity sensor, comprising a plastic shell 1, a humidity sensor 2 and a temperature sensor 4, the humidity sensor 2 and the temperature sensor 4 both adopt a quartz tuning fork structure, and the moisture-sensitive material is physically spin-coated on Between the two poles 3 of the humidity sensor; the temperature-sensitive material is physically spin-coated between the two poles 6 of the temperature sensor; the temperature sensor 4 and the humidity sensor are all located inside the plastic casing 1, and the humidity sensor 2 of the humidity sensor is connected to the second pole of the humidity sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com