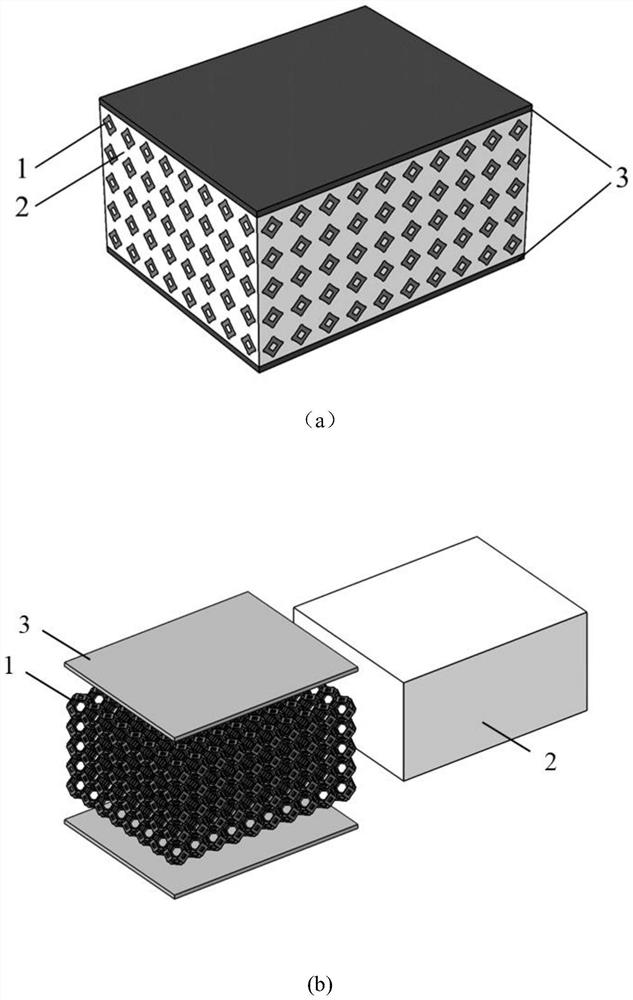

Damping material filled open-cell foam metal type underwater sound absorption composite structure

A technology of open-cell foam and damping materials, which is applied in the direction of metal layered products, sound-generating devices, and synthetic resin layered products. It can solve the problems of loss of elasticity, loss of vibration and noise absorption, and improve sound absorption performance and water pressure resistance. performance, improved sound absorption performance, and the effect of good underwater sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Examples of materials:

[0041] Metal aluminum: density 2700kg / m 3 , Young's modulus 70GPa, Poisson's ratio 0.33.

[0042] Soft polyurethane: density 980kg / m 3 , Young's modulus 6MPa, Poisson's ratio 0.493, loss factor 0.5.

[0043] Hard polyurethane: density 1100kg / m 3 , Young's modulus 30MPa, Poisson's ratio 0.490, loss factor 0.3.

[0044] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0045] The structure size of embodiment:

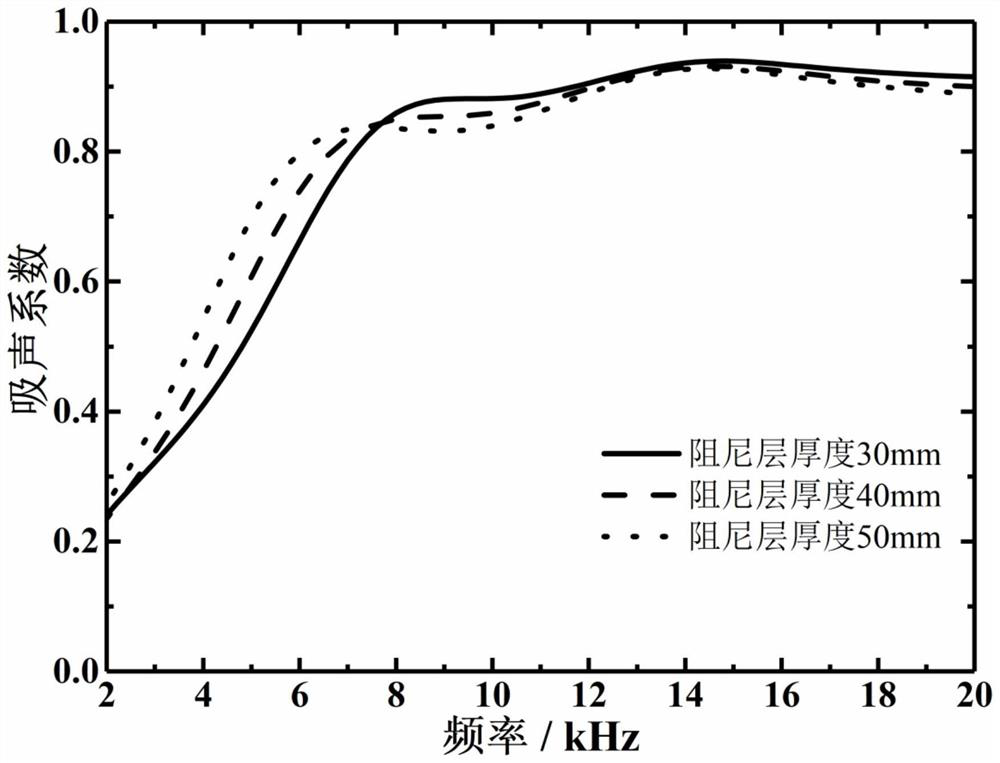

[0046] The simulation calculation uses the tetrahedron model of open-cell aluminum foam, the cell side length is 8mm, the diameter of the aluminum foam skeleton is 2mm, the porosity is 70.1%, and the thickness of the aluminum foam is 50mm; the hard polyurethane covering layer is the same up and down, and the thickness is 2mm.

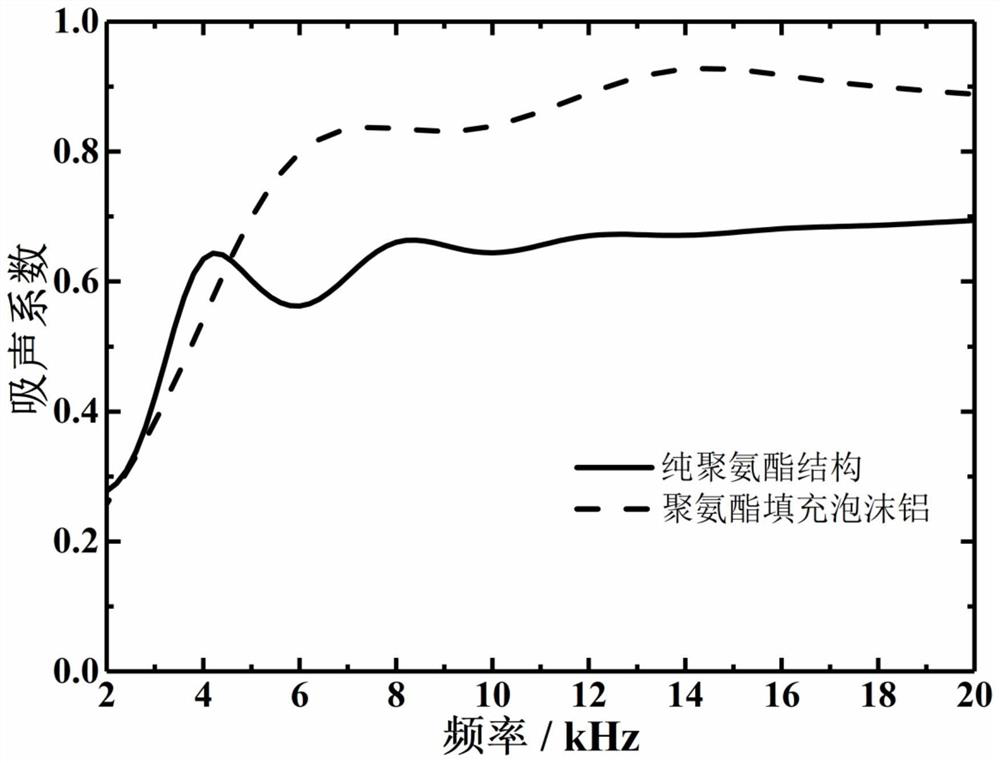

[0047] Using the above materials and structural dimensions to carry out numerical simulations, the results of the examples are given as follows:

[0048] The sound absorption pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com