Composite graphite bipolar plate and preparation method

A composite graphite and bipolar plate technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, fuel cells, etc., can solve the problems affecting the overall performance and yield of fuel cells, poor bonding between metal plates and graphite flow channels, graphite The plate bonding process is complex and other issues, to achieve the effect of improving graphite strength, improving toughness and strength, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

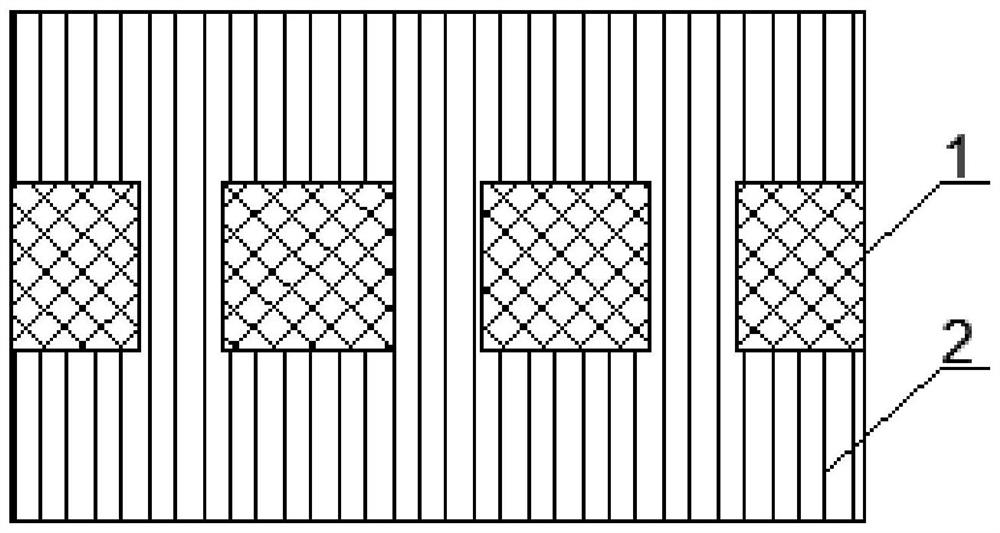

[0029] This embodiment provides a composite graphite bipolar plate, such as figure 1 shown, including:

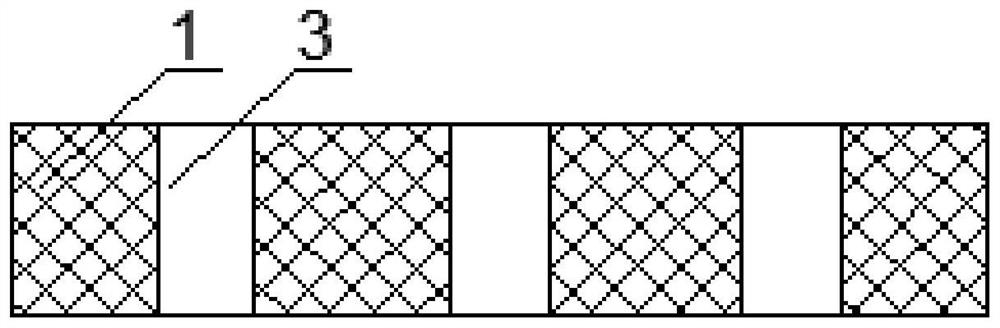

[0030] expanded metal sheet 1, such as figure 2 As shown, there are a plurality of through holes 3; optionally, the thickness of the porous metal plate 1 is 0.1-0.4mm, for example, 0.1mm, 0.2mm, 0.3mm or 0.4mm can be selected; optionally, the The diameter of the through hole 3 is 10-100um, for example, 10um, 50um or 100um can be selected; optionally, the porous metal plate 1 is a titanium plate, a nickel plate or a stainless steel plate;

[0031] Runner ridges 2 are arranged on opposite surfaces of the porous metal plate 1;

[0032] a fixing column, arranged in the through hole 3 corresponding to the runner ridge 2, and the fixing column and the runner ridge 2 are integrally molded;

[0033] Optionally, the materials of the flow channel ridge 2 and the fixing column include: 5-10 parts of flake graphite with a diameter of 20-50 mm, 1-5 parts of graphene, 60-65 parts of ...

Embodiment 2

[0039] This embodiment provides a method for preparing a composite graphite bipolar plate, including:

[0040] Mix 5-10 parts of flake graphite with a diameter of 20-50 mm, 1-5 parts of graphene, 60-65 parts of graphite powder, 12-18 parts of phenolic resin and 1-5 parts of thermally conductive carbon fiber to form a mixture; optionally, use The high mixer stirs for 1-3h under the condition of 1500-3000r / min.

[0041] The mixture was molded on a perforated metal sheet to form the runner ridges and anchor posts.

[0042] The preparation method of the composite graphite bipolar plate in this embodiment provides a method for rapid prototyping and effective improvement of the bonding force. Effective bonding is achieved by embedding graphite powder into the porous plate, and the toughness and strength of the graphite plate are improved through the metal skeleton, effectively improving the bipolar plate. The comprehensive performance of the polar plate is conducive to reducing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com