Microwave degradation treatment unit for solid wastes of oil field

A technology of solid waste and microwave degradation, applied in the field of oil field solid waste treatment, can solve the problems of secondary pollution, unfavorable oil recovery, incomplete treatment, etc. Wide range of effects with simple and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

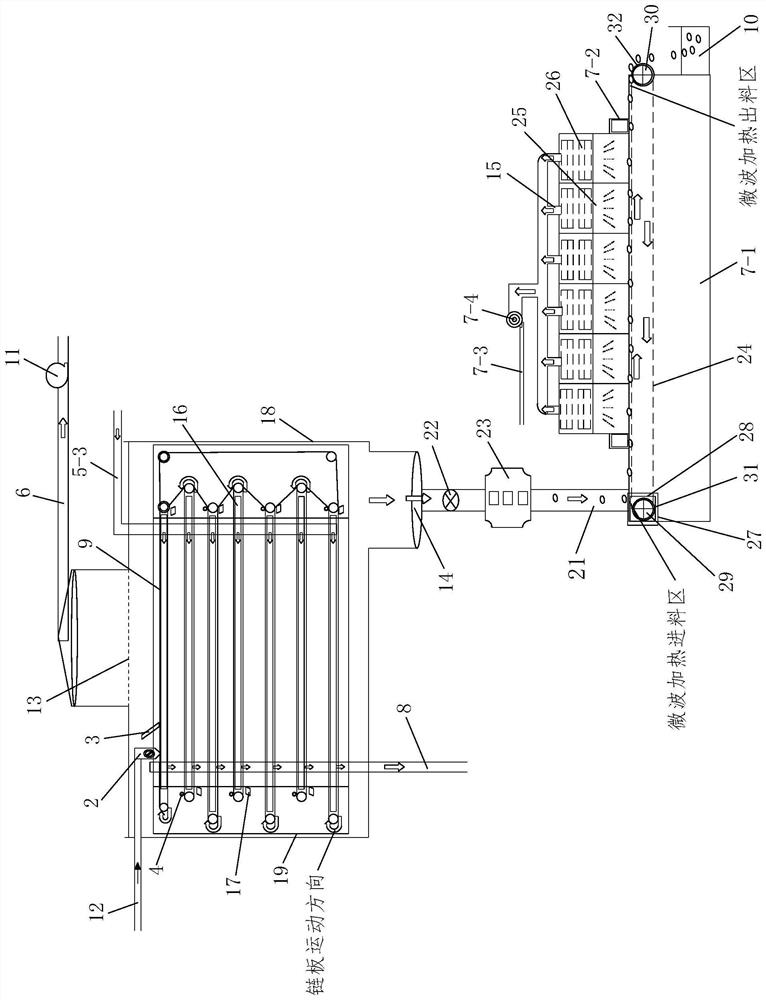

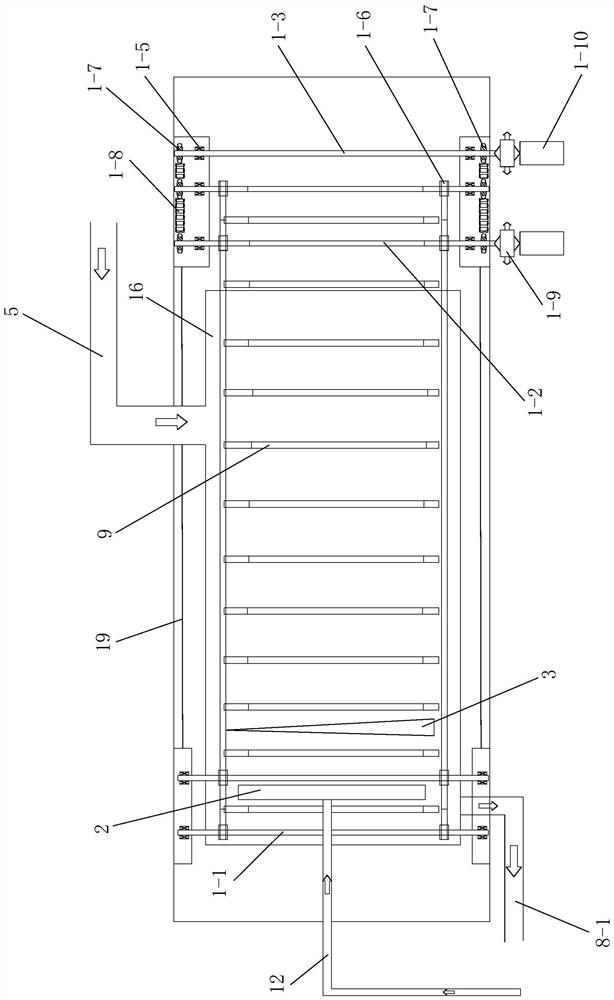

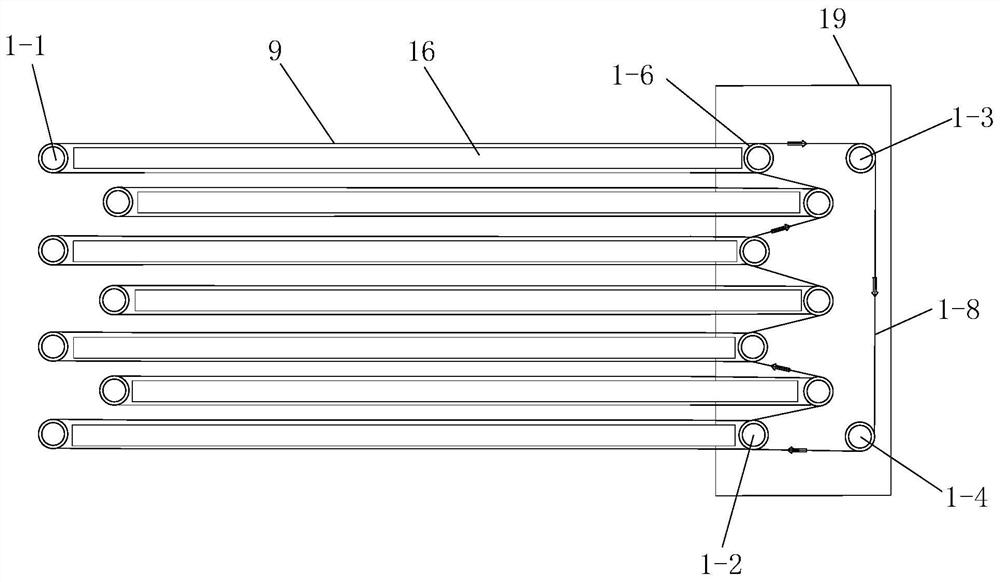

[0052] Such as figure 1 As shown, the present invention includes a material delivery pipeline 12, a low-temperature negative pressure drying unit, a steam delivery pipeline 5, an air-water pipeline 8, a concentrated material forming system and a microwave degradation drying device, and the outlet of the material delivery pipeline 12 is connected to the The feed port of the low temperature negative pressure drying unit is connected and the preheated solid waste is sent into the low temperature negative pressure drying unit for drying. The outlet of the steam delivery pipeline 5 is connected to the low temperature negative pressure drying unit. The compressed steam inlet of the drying unit is connected and provides the hot steam required for the concentration and drying of solid waste for the low-temperature negative pressure drying unit; the low-temperature negative pressure drying unit includes a dryer box 18, and the dryer box The top center of the body 18 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com