Comprehensive air floating system for pressure dissolution electrolysis

A complete set of equipment and comprehensive technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of uneven ionization and dissolution of metal ions on the surface, long operation period, and limitations of popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

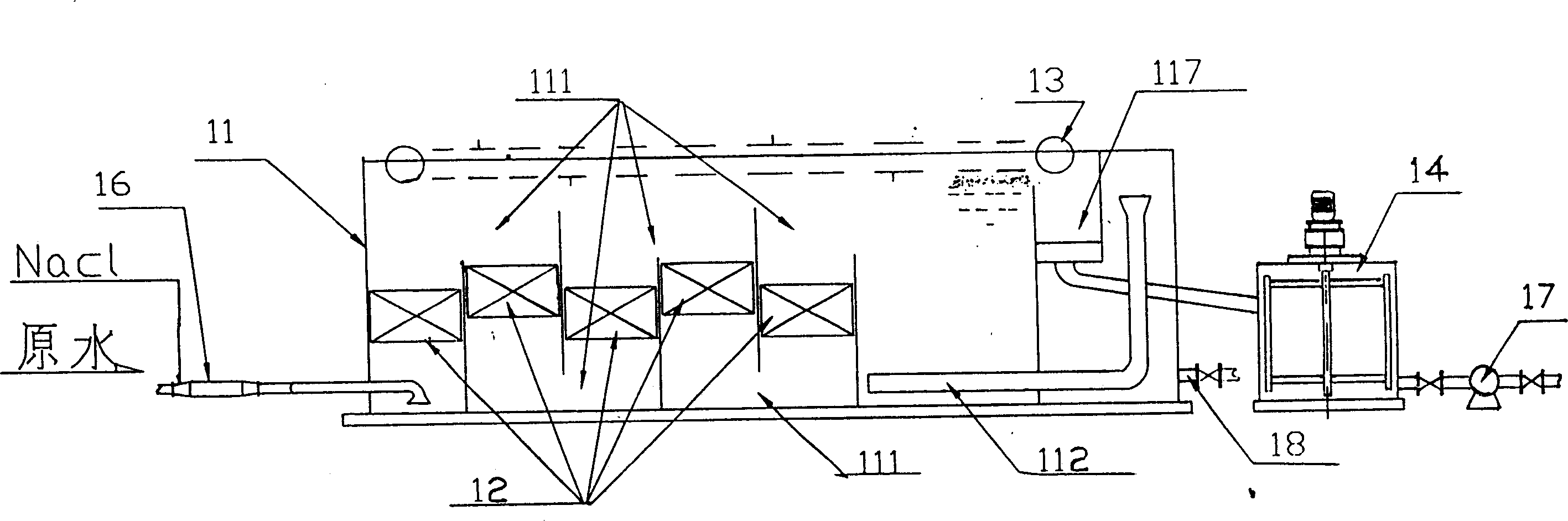

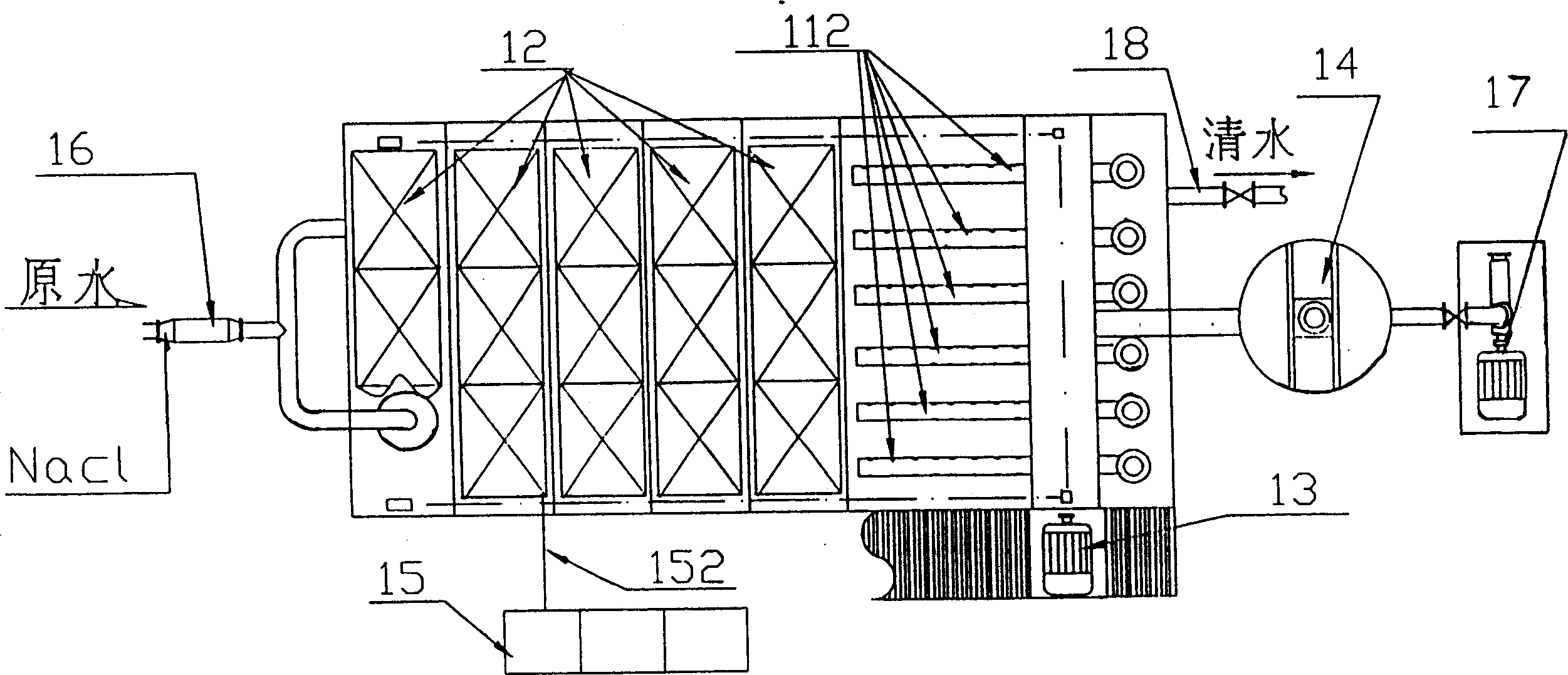

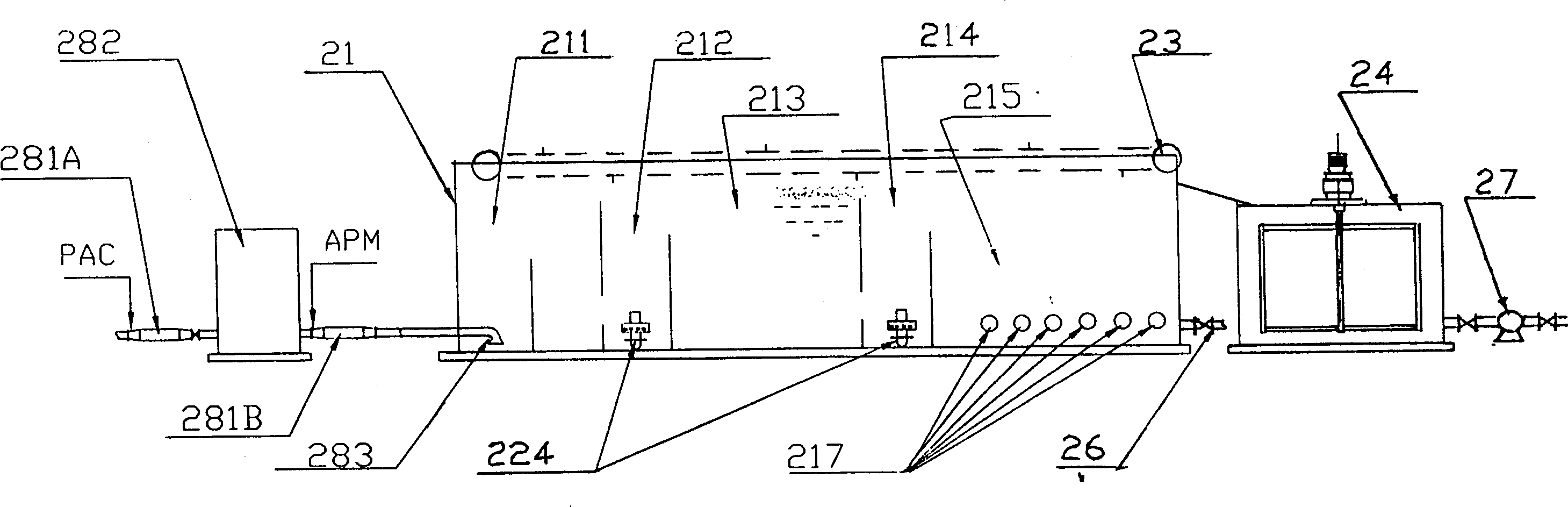

[0089] The actual engineering experiment design example of the pressure-soluble electrolysis comprehensive air flotation complete set is as follows:

[0090] Daily processing 3500M 3 Wastewater in papermaking, see Table 4 for influent and effluent water

[0091] Table four:

[0092]

[0093] Other parameters are as follows:

[0094] The air flotation pool is 12M long, 4M wide and 1.9M deep.

[0095] Moisture content of scum: 97%.

[0096] Every 1kgCOD removed cr Sludge production (absolutely dry): 0.6kg.

[0097] Every 1kgCOD removed cr Power consumption: 0.06 degrees.

[0098] Every 1kgCOD removed cr Consumption of inorganic flocculant 0.4kg (AL 2 o 3 9% liquid medicament).

[0099] Every 1kgCOD removed cr Consumption of polymer coagulant aid 0.02kg (medicine solution with polypropylene content of 2%).

[0100] Every 1kgCOD removed cr Consumption of NaCl is about 0.0002kg. Every 1kgCOD removed cr Consumption of ferrous sulfate 0.0001kg.

[0101] The total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com