Method for catalytic wet oxidative degradation of small molecular organic acid and ammonia-nitrogen solution

A small molecule organic acid, catalytic wet oxidation technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems that affect the stable and effective operation of the biochemical treatment system, increase the pollution degree of the receiving water body, increase the treatment load, etc. Wide range, fast processing speed, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

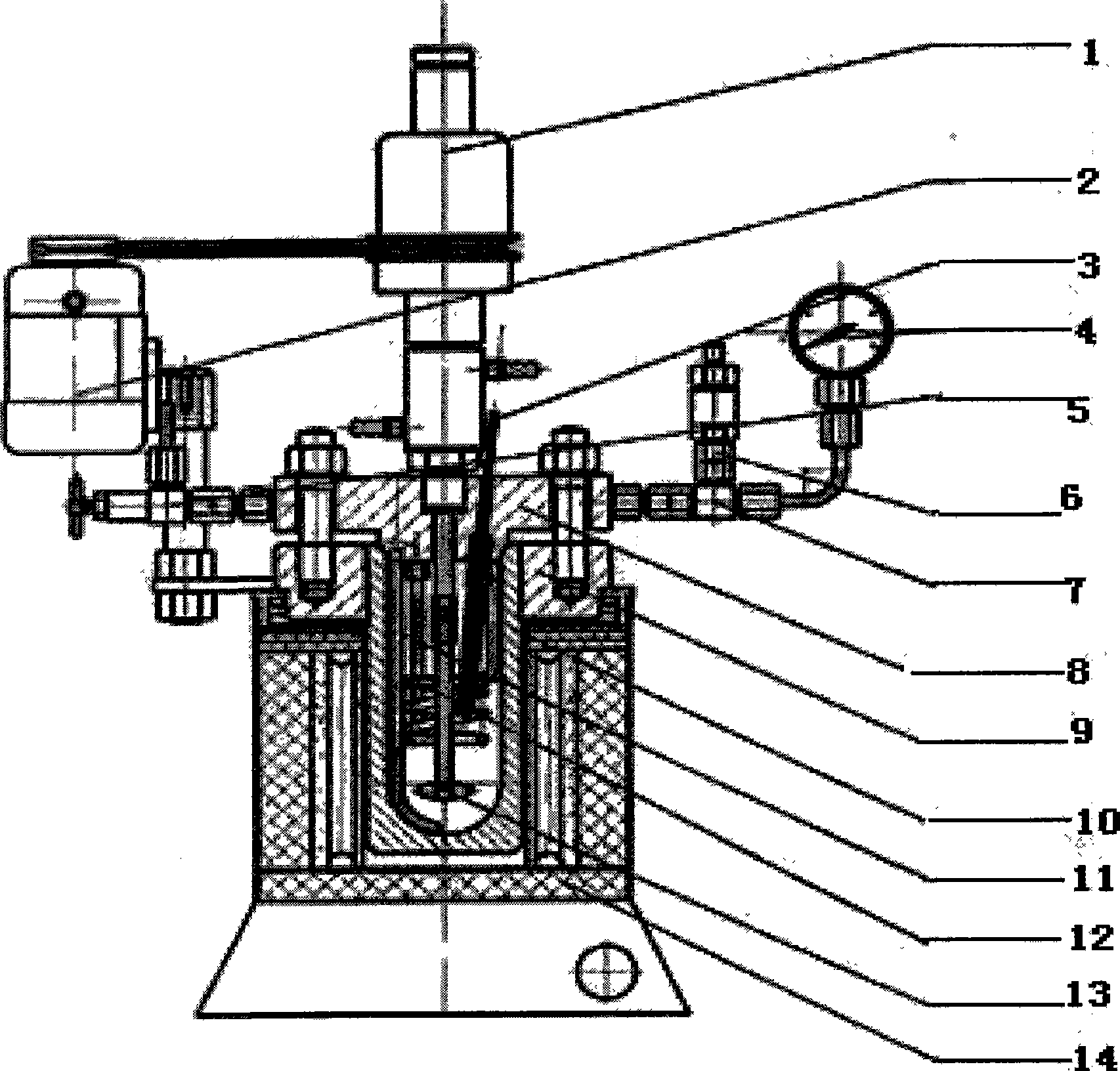

[0051] Put 0.5g of Mn / Ce catalyst and 500mL of organic acid solution (TOC about 434mg / L) prepared according to Table 1 into the reaction kettle, seal it, set the oxygen partial pressure to 1.0Mpa, stir at 500r / min, heat up to 200°C Take a sample from the liquid inlet and record it as the "0" time sample, and then take a sample every 30 minutes until 120 minutes. A total organic carbon analyzer (model TOC-V) produced by Shimadzu Corporation of Japan was adopted. CPH ) measure the total organic carbon (TOC) of the sample after treatment, and calculate the removal rate of TOC.

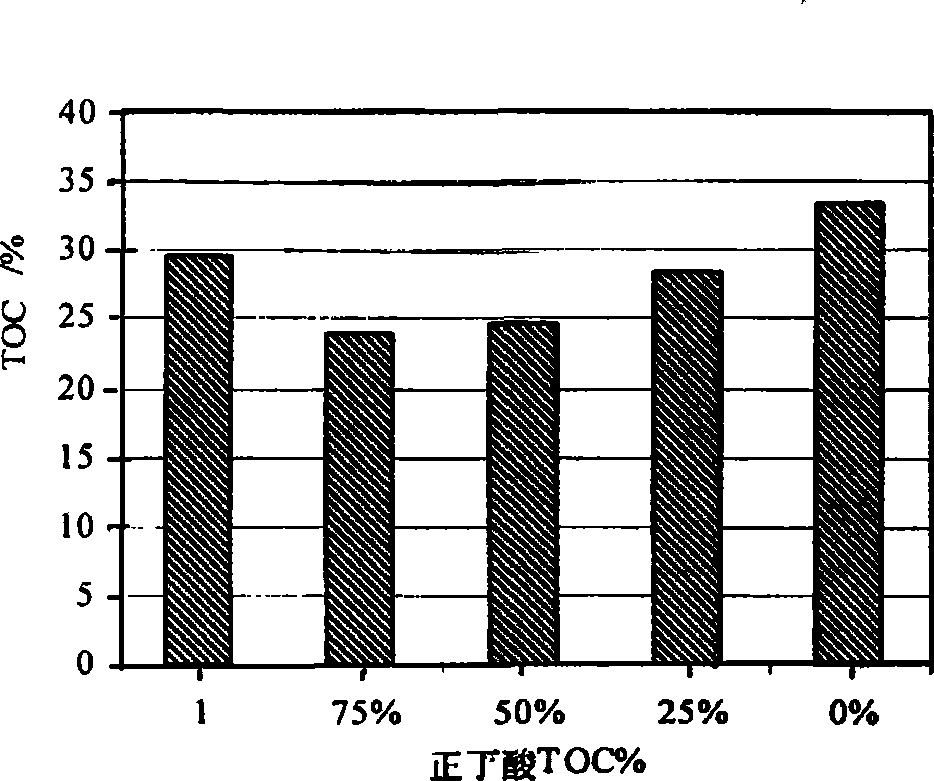

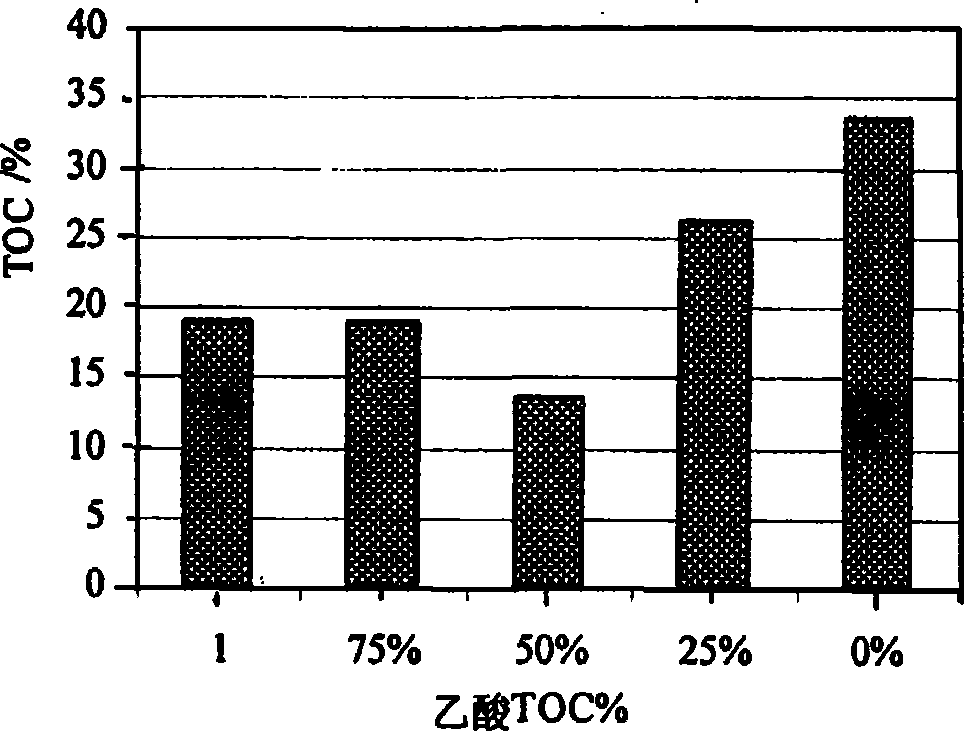

[0052] Different ratios of n-butyric acid and n-hexanoic acid catalyzed wet oxidation reached the preset temperature, and the removal rate of TOC at 0 min was shown in figure 2 : The TOC removal rate of mixed acids is lower than that of n-butyric acid or n-hexanoic acid, and the TOC removal rate of n-butyric acid is the lowest when the TOC is 75% and 50%, indicating that there is an interaction between ...

Embodiment 2

[0057] The reaction solution is 500mL of n-butyric acid solution (TOC is about 434mg / L), and five kinds of ammonia nitrogen solutions with different concentrations are added to the reaction solution respectively, so that the concentrations of ammonia nitrogen in the reaction solution are 0, 120, 260 and 400mg / L respectively, corresponding to The pH values of the solutions are 3.33, 6, 8 and 10 respectively, the prepared ammonia solution and 0.5gMn / Ce catalyst are added to the reaction kettle respectively, sealed, the oxygen partial pressure is set to 1.0Mpa, the stirring speed is 500r / min, and the heating After rising to 200°C, take a sample from the liquid inlet and record it as the "0" time sample, and then take a sample every 30 minutes until 120 minutes. The TOC and pH of the samples were measured.

[0058] The catalytic wet oxidation degradation of landfill leachate includes both the degradation of organic matter and the degradation of ammonia nitrogen. During the degra...

Embodiment 3

[0064] The reaction solution is 500 mL of ammonia nitrogen solution (about 512 mg / L of ammonia nitrogen), and five kinds of n-butyric acid solutions with different concentrations are added to the reaction solution respectively, so that the concentration of the n-butyric acid solution in the reaction solution is respectively 0, 110, 215, 320 and 430mg / L, put the prepared solution and 0.5gMn / Ce catalyst into the reaction kettle, seal it, set the oxygen partial pressure to 1.0Mpa, stir the speed to 500r / min, heat up to 200°C and take a sample from the liquid inlet and record it as "0 "Time sample, and then take a sample at intervals of 30 minutes until 120 minutes. Measure the ammonia nitrogen in the sample, and calculate the removal rate of ammonia nitrogen.

[0065] Ammonia nitrogen has a certain effect on the degradation of organic acids, and the presence of organic acids may also affect the degradation of ammonia nitrogen. In order to study the effect of organic acids on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com