Chemical disinfection harmless treatment technology for medical waste

A technology for medical waste and chemical disinfection, which is applied in the direction of waste disinfection or sterilization methods, chemistry, disinfection, etc., can solve the problems of increased pollution and control risks, high requirements for environmentally friendly disposal of products, and high cost of treatment equipment to achieve good promotion Application value, thorough disinfection and sterilization, and the effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

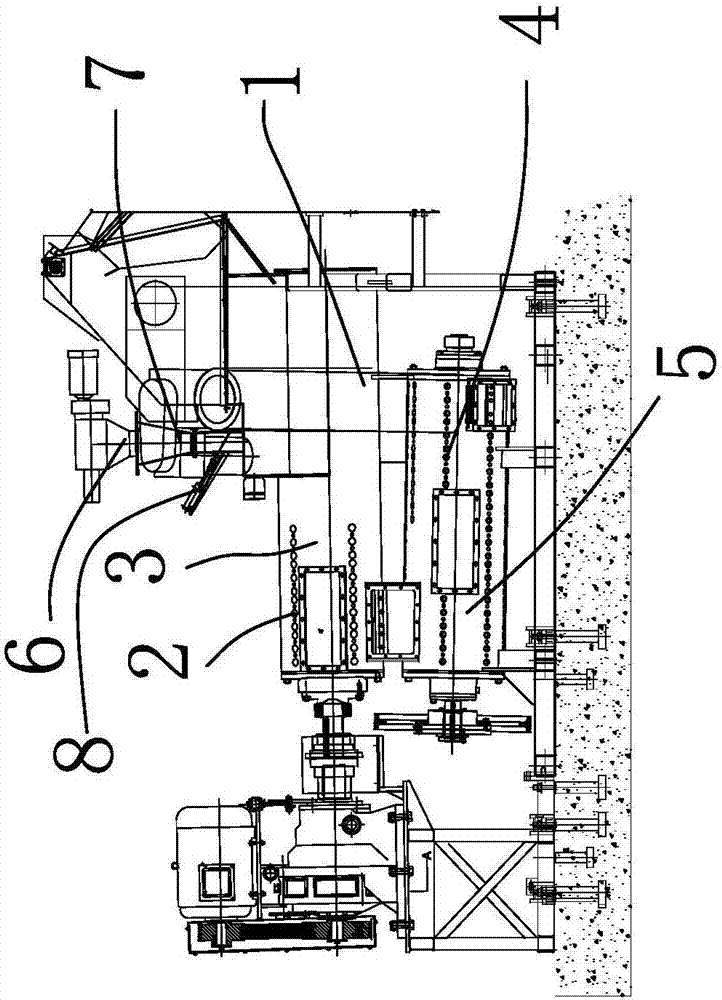

[0022] In the figure, the tank warehouse 1; the coarse crushing mechanism 2; the coarse crushing space 3; the fine crushing mechanism 4; the fine crushing space 5; the medicine powder conveyor 6; the medicine powder delivery bin 7;

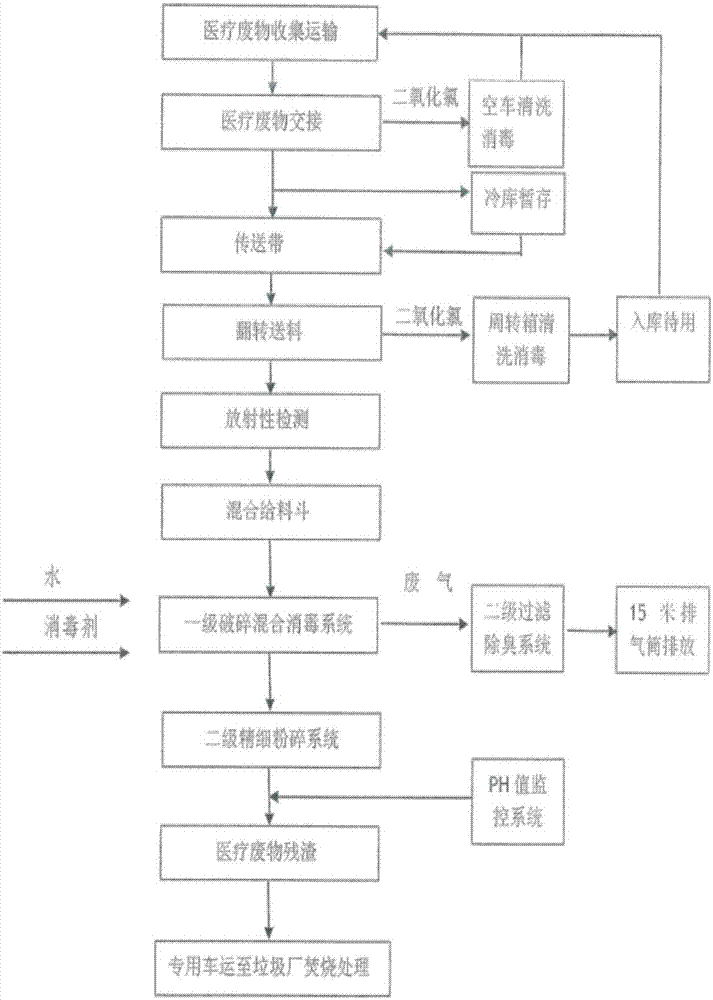

[0023] Such as figure 1 As shown, the chemical disinfection and harmless treatment process of medical waste includes crushing and disinfection treatment of medical waste, including the following steps: Step 1, collect and transport medical waste by transport vehicle, and dispose of medical waste after handover The waste is placed on the conveyor belt for transportation, and at the same time, the empty transport vehicle after dumping the medical waste is cleaned and disinfected by chlorine diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com