An oilfield solid waste treatment agent and resource treatment process

A treatment agent and oilfield technology, which is applied in the field of oilfield solid waste treatment agent and resource treatment process, can solve the problems of secondary pollution, unfavorable oil recovery, long decomposition period, etc. The process is simple and easy, and the separation speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

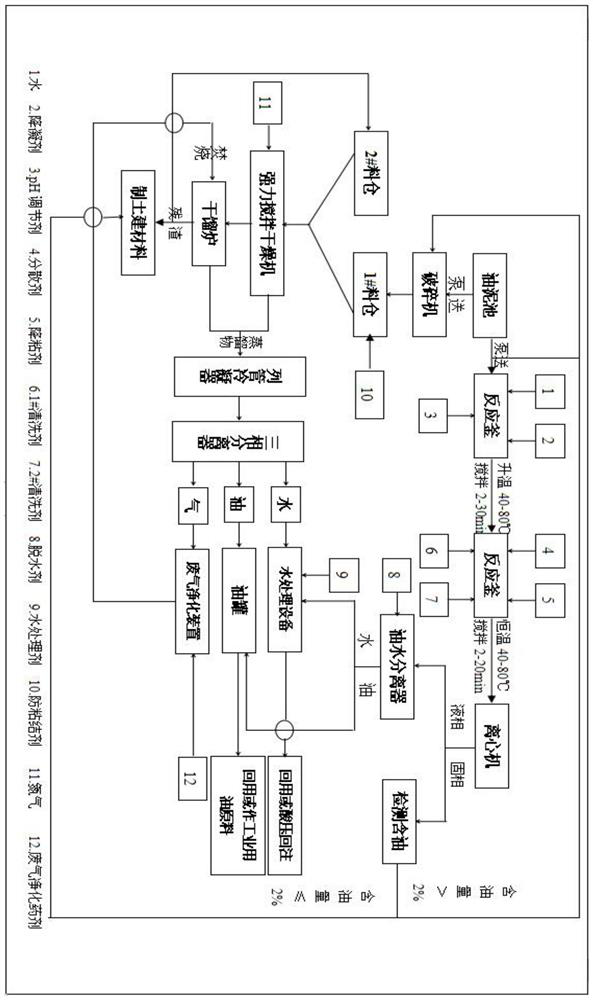

Method used

Image

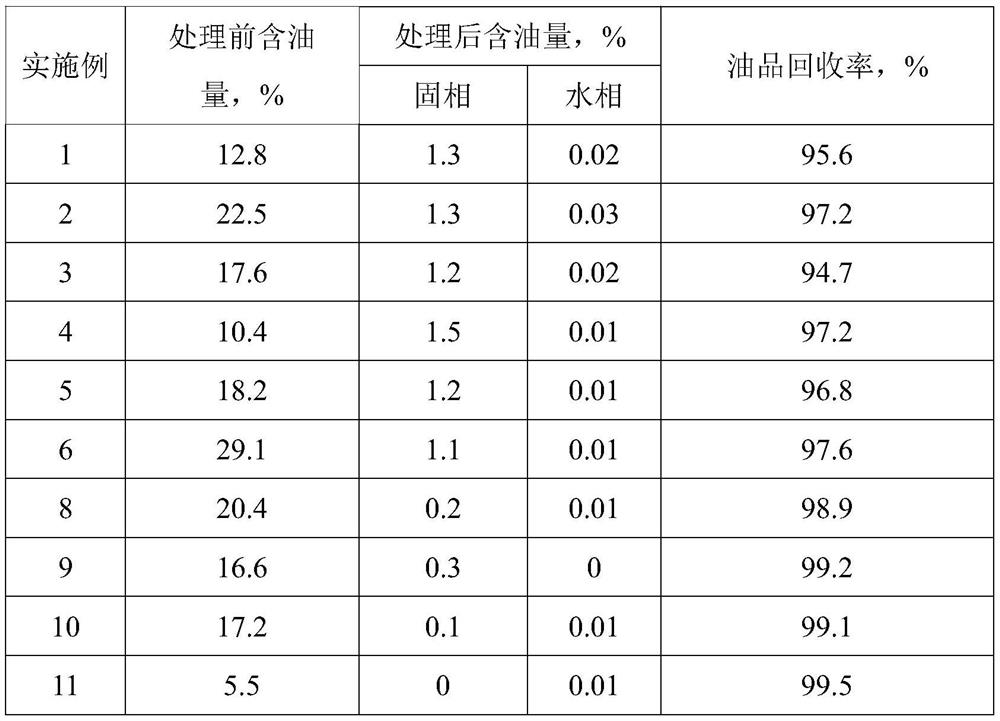

Examples

Embodiment 1

[0055] The dosage of oilfield solid waste and treatment agent components is as follows:

[0056] All are parts by weight (unit: kilogram) and the total weight is 100 parts

[0057] 50 parts of oilfield solid waste, 0.04 parts of pH regulator acetic acid, 0.06 parts of pH regulator soda ash, 0.02 parts of pour point depressant EVA28-400.02 parts, 0.06 parts of dispersant calcium lignosulfonate, 0.4 parts of viscosity reducer, cleaning agent A (TX- 4 and MOA-25 0.2 parts each), cleaning agent B (sodium lauryl sulfate, sodium lauryl polyoxyethylene ether sulfate and polyethylene glycol monomethyl ether laurate 0.2 parts each), dehydrating agent It is 1.0 part of TA1031, and the rest is water.

Embodiment 2

[0059] The dosage of oilfield solid waste and treatment agent components is as follows:

[0060] All are parts by weight (unit: kilogram) and the total weight is 100 parts

[0061] 50 parts of oilfield solid waste, 0.03 parts of pH regulator industrial hydrochloric acid, 0.05 parts of pH regulator industrial caustic soda, 0.01 part of pour point depressant BEM-5P, dispersant OEP-70 (0.02 part), 0.5 part of viscosity reducer, cleaning agent A (0.22 parts each of AES and TX-4), cleaning agent B sodium dodecyl ethyl succinate 1.2 parts, dehydrating agent is DY-101 and TA1031 mixed at 1.2:1, add 0.5 parts, and the rest is water.

Embodiment 3

[0063] The dosage of oilfield solid waste and treatment agent components is as follows:

[0064] All are parts by weight (unit: kilogram) and the total weight is 100 parts

[0065] 50 parts of oilfield solid waste, 0.04 parts of pH regulator industrial hydrochloric acid, 0.06 parts of pH regulator soda ash, 0.01 parts of pour point depressant WRT and BEM-5P, 0.02 parts of dispersant XF-35 and calcium lignosulfonate, viscosity reducer 0.4 parts of cleaning agent, cleaning agent A (0.25 parts of MOA-20 and TX-7 and 0.16 parts of octadecyltrimethylammonium chloride), cleaning agent B dehydrating agent is cetyl sulfopropyl betaine and poly Add 0.7 parts of ethylene glycol monomethyl ether laurate after mixing 1:1, add 0.4 parts after mixing SAE118 and LE-28 at 1:1, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com