Inclined tool apron

A tilting and tool seat technology, which is applied to the accessories of tool holders, tools for lathes, tool holders, etc., can solve the problems of unsteady cutting pressure, unable to maintain vertical state, and unable to guarantee cutting quality, so as to improve cutting Quality, reduced processing costs, constant cutting pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

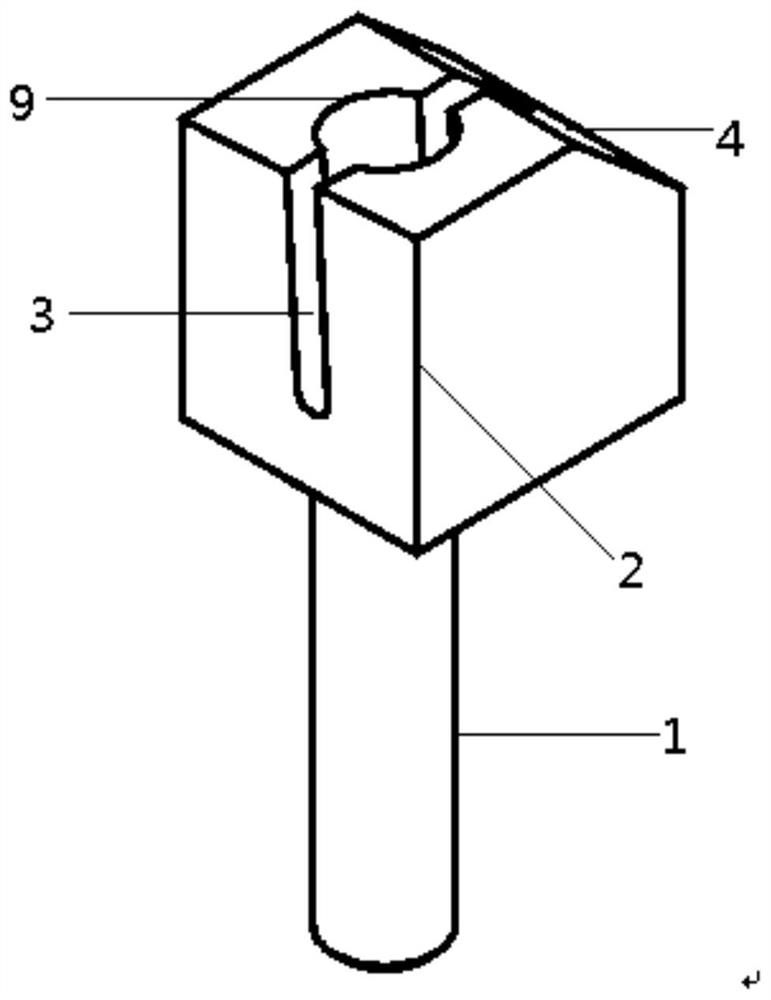

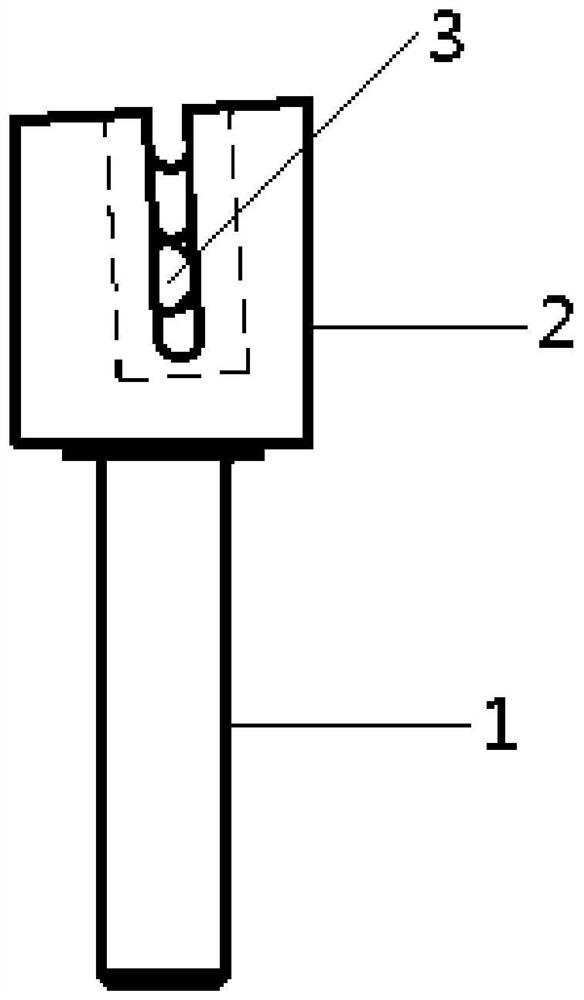

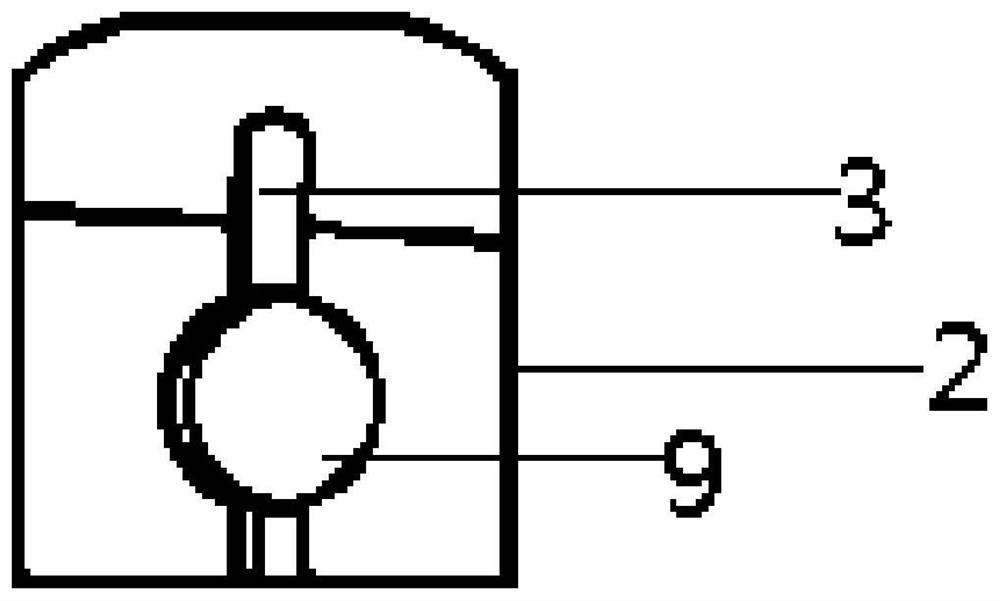

[0039] Such as figure 1 As shown, a kind of inclined tool seat is used for processing arc-shaped or special-shaped processed materials with a bending arc of 35°. The height of seat head 2 is 13.25mm, the width of tool seat head 2 is 11mm, the length of tool seat head 2 is 12.5mm, the depth of assembly groove 3 is 9.86mm, the width of assembly groove 3 is 0.13mm, and the inclination of assembly groove The angle is 35°, that is, the inclination angle of the inclined surface 4 is 35°, the assembly groove 3 is formed with a hole 9 for assembly along the horizontal direction, and the diameter of the hole 9 for assembly is 4.76mm, wherein the inclined tool holder The accuracy of the total height, the height of the tool handle 1, the length of the tool holder head 2, the width of the tool holder head 2, the depth of the assembly groove 3 and the width of the assembly groove 3 is ±0.03mm. Through the parameter design of the inclined knife seat, it can be ensured that the inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com