Porous multi-row drilling machine for stainless steel tube silencer connected tubes

A stainless steel pipe and muffler technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, positioning devices, etc., can solve the problems of low efficiency, poor practicability, and affecting drilling accuracy, etc., to achieve convenient and fast collection, Effects of improving stability and reliability and increasing the collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

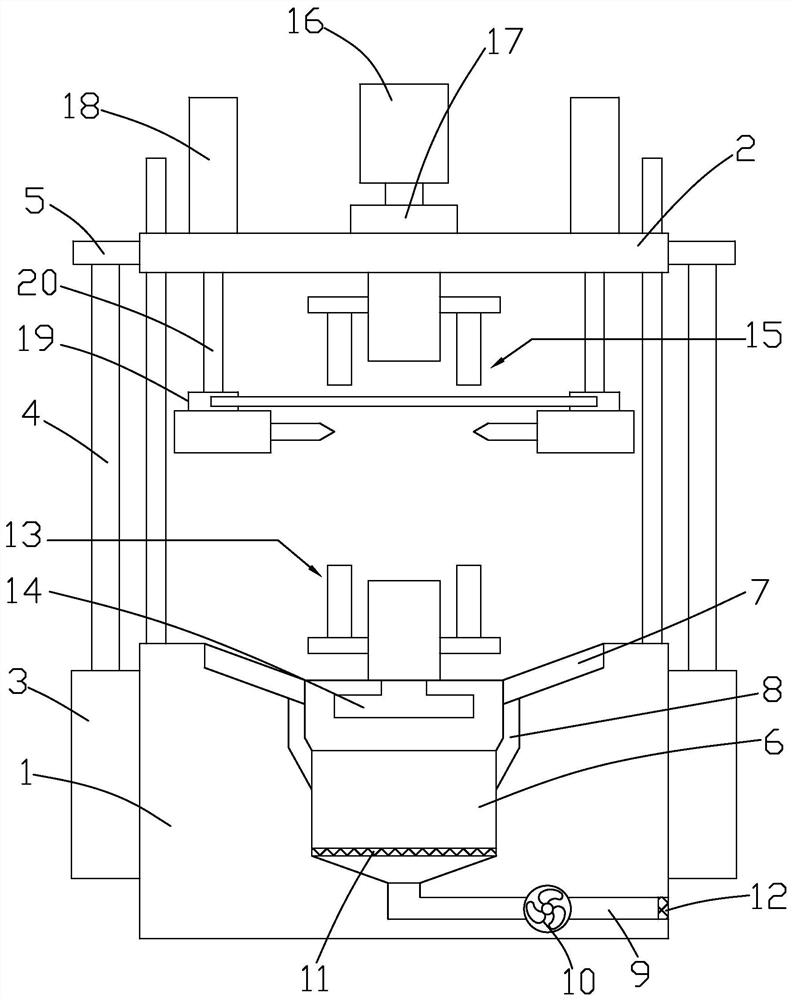

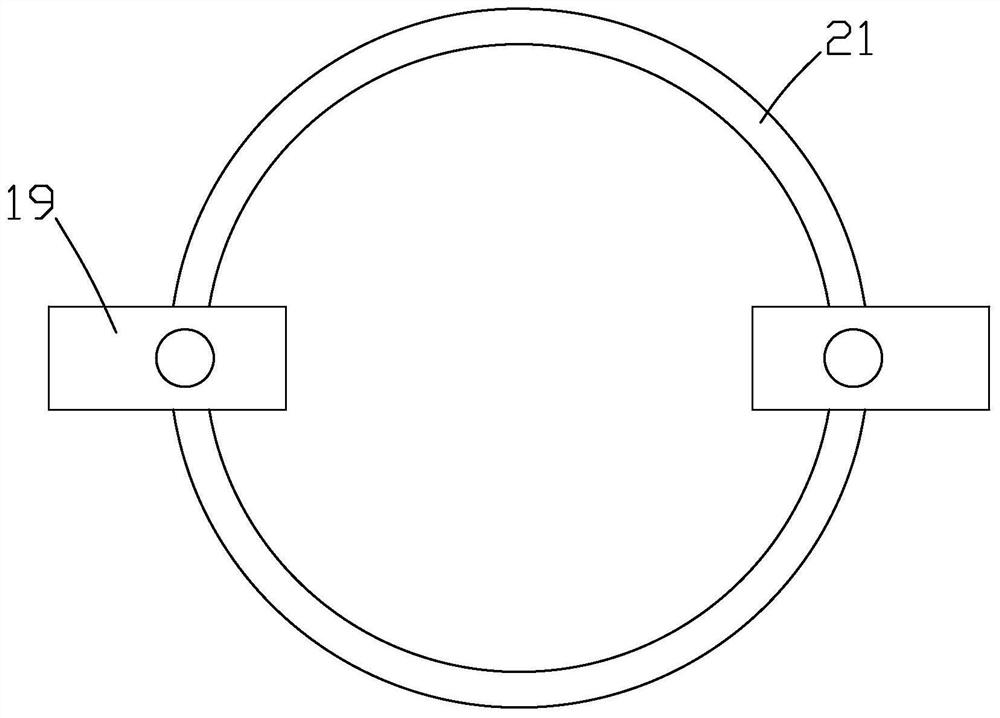

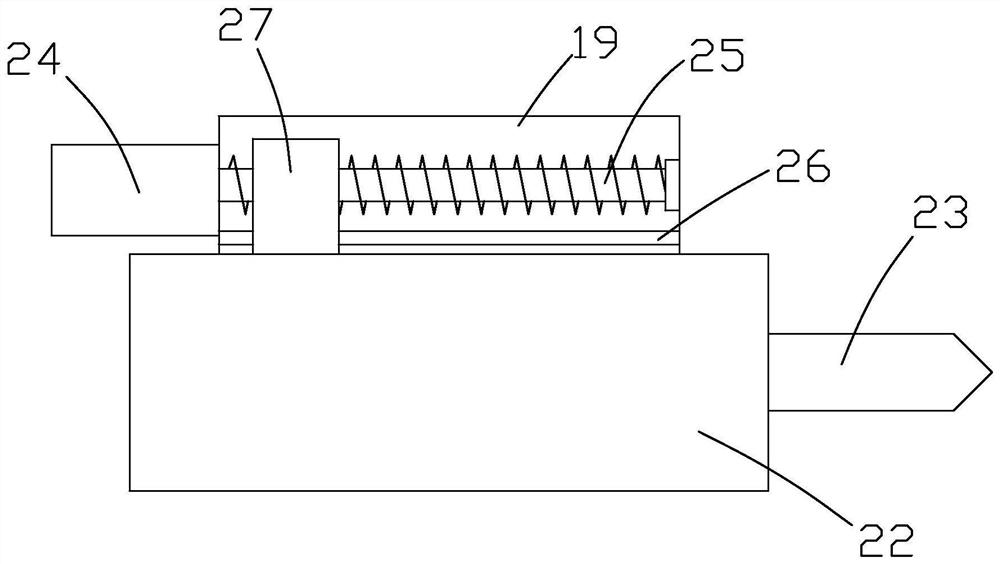

[0029] Such as Figure 1 to Figure 5 Shown here is a multi-row drilling machine with multiple holes for stainless steel pipe muffler pipes of the present invention, including a base 1, a lifting platform 2, a debris handling mechanism, a first clamping mechanism 13, and a second clamping mechanism 15 and the drilling mechanism. The lifting platform 2 is connected to the upper part of the machine base 1 through a lifting assembly. The lifting assembly includes a first cylinder 3, a first piston rod 4, an ear plate 5 and a positioning rod. The ear plate 5 is fixedly connected to the lifting platform 2 On the side surface, the first cylinder 3 is fixedly connected to the side surface of the base 1, the first cylinder 3 is connected to the ear plate 5 through the first piston rod 4, and the bottom end of the positioning rod is fixedly connected to the top surface of the base 1, positioning The top end of the rod penetrates the lifting plate, and the first cylinder 3 drives the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com