Austenitic stainless steel pipe silencer connecting pipe and manufacturing method thereof

A technology for stainless steel pipes and manufacturing methods, applied to other manufacturing equipment/tools, manufacturing tools, tubular objects, etc., which can solve the problems of reduced production efficiency, easy shaking, increased production costs, etc., to increase the scope of use and increase welding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

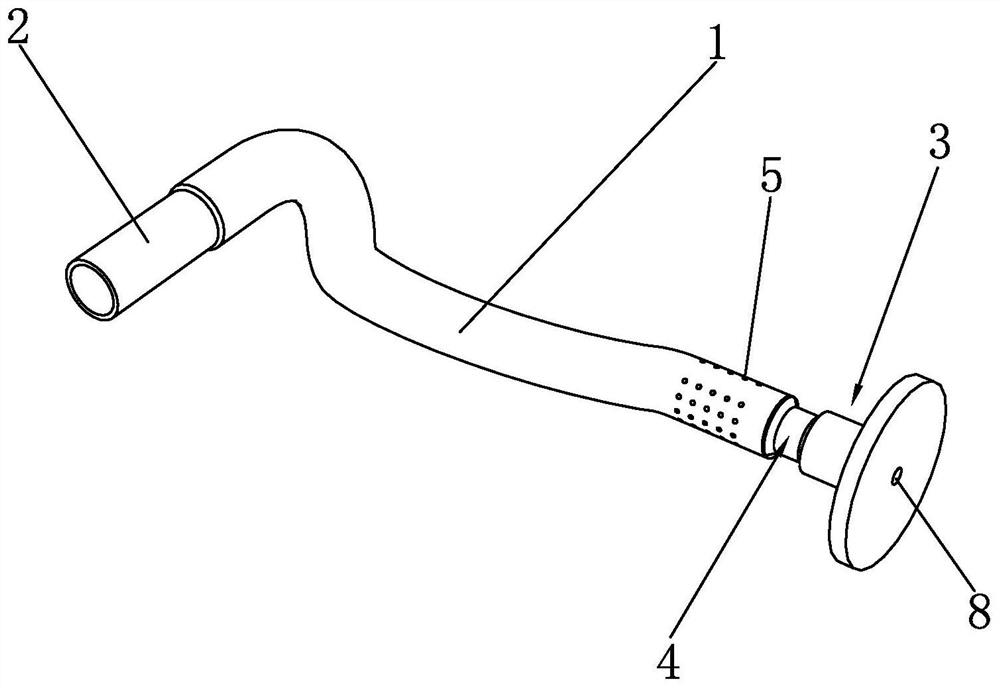

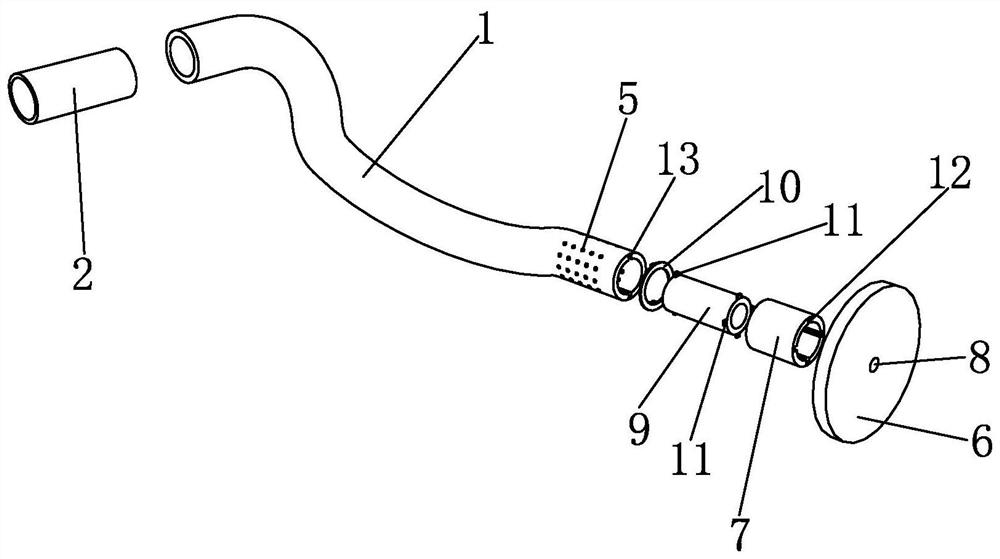

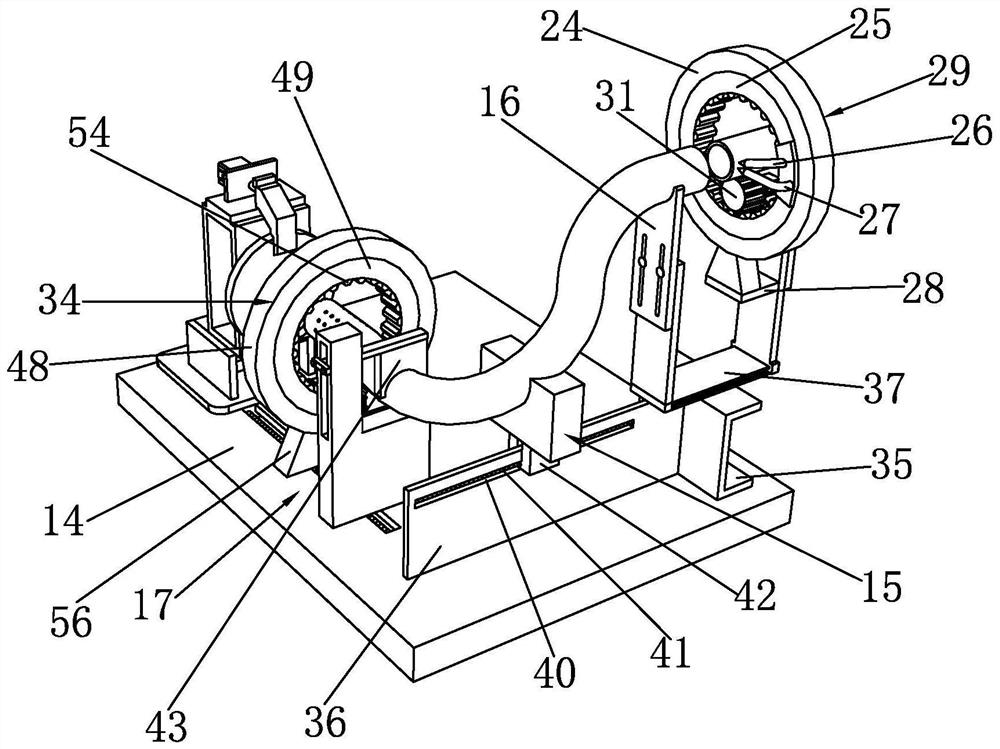

[0044] Such as Figure 1 to Figure 2 As shown, it is an austenitic stainless steel pipe muffler connecting pipe of the present invention, including a pipe body 1, an air intake pipe section 2 and a fixed pipe section 3, the pipe body 1 is in an irregular tubular shape, and the air intake pipe section 2 is welded on one end of the pipe body 1, An adjustment assembly 4 is connected between the fixed pipe section 3 and the other end of the pipe body 1. The end of the pipe body 1 close to the fixed pipe section 3 is evenly distributed with silencer holes 5. The adjustment assembly 4 is used to adjust the opening and closing of the silencer holes 5. The adjustment assembly 4 After the adjustment is completed, weld with the pipe body 1 and the fixed pipe section 3 respectively.

[0045] The diameter of the air intake pipe section 2 is smaller than that of the pipe body 1, and the air intake pipe section 2 and the pipe body 1 are connected by welding. The setting of the intake pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com