An Inverted Step Shaft Structure and Blowout Reduction Method

A step-type, vertical well technology, applied to underwater structures, infrastructure engineering, drainage structures, etc., can solve the problems that cannot avoid the possibility of blowout, increase the pressure change of pipelines, and troublesome maintenance of vertical wells, so as to reduce the occurrence of vertical well blowout, The effect of stable air pressure and increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

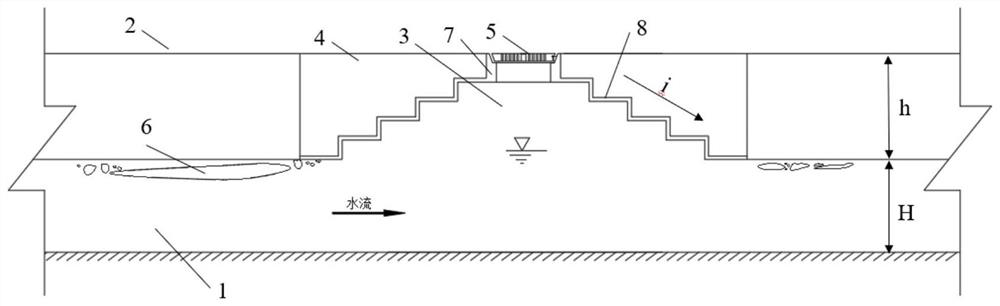

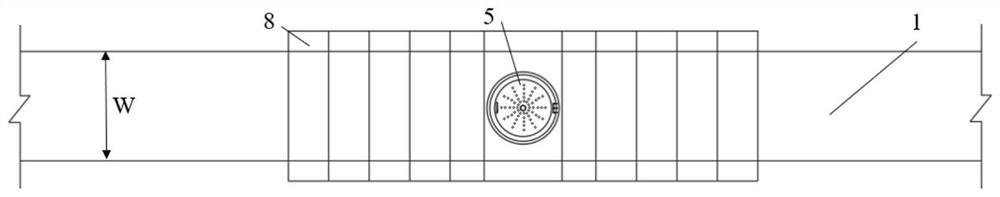

[0037] The schematic diagram of the multi-stage connecting urban drainage pipe shaft structure is shown in figure 1 , the vertical shaft 3 is arranged on the top of the underground pipeline 1 to communicate with the underground pipeline 1 and the ground 2 , and the well cover 5 is arranged on the top of the vertical shaft 3 .

[0038] The shape of one side of the shaft 3 is stepped (shaft step 8), mirrored along the axis of the hole, the width of the step is larger than that of the underground pipeline 1, and the material is steel frame, reinforced concrete, high-strength synthetic material, etc., which can be integrally formed or assembled .

[0039]The first step of the shaft step 8 is flush with the ground 2, and a cylinder is dug out in the center, which is 3 shafts; the last step is connected to the top of the underground pipeline 1, and the slope of the middle step is i, generally i=30° ~60° is appropriate; the backfill 4 above the steps is flush with the ground 2. Des...

Embodiment 2

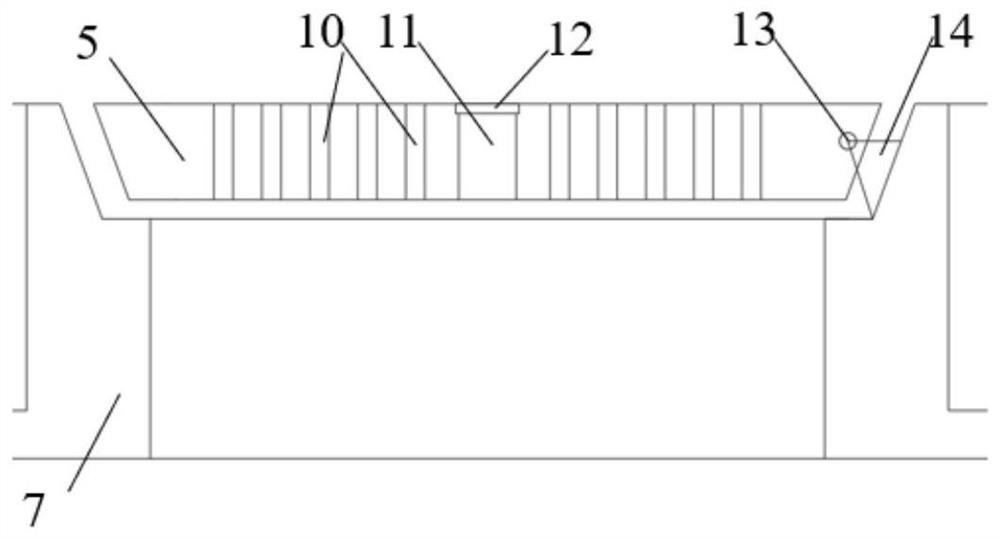

[0043] The shaft 3 communicates with the atmosphere on the ground 2 and the underground pipeline 1 , and the manhole cover 5 assembly is arranged on the top of the shaft 3 . The structure of manhole cover 5 components is as follows Figure 5 to Figure 6 As shown, it mainly includes the following components: well cover cavity 504, well cover 5 base, well cover support 505, well cover hinge 506, well cover rib 501, rib track 502, vent hole 10, middle hole, well cover 5 handles, limit Bit soft rope 503, hook, cushion 508. The well cover 5 is a conical body with a circular (or square) flat plate. When in use, the flat plate is placed horizontally and flush with the ground 2. The manufacturing material is generally cast iron, plastic, concrete or synthetic material, and the gravity is G.

[0044] The shape of the well cover cavity 504 is an inverted cone, and the cross-sectional shape is an inverted isosceles triangle. The base angle of the isosceles triangle is less than 60°, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com