Cold starting system and cold starting method for mining dump vehicle

A mining dump truck, cold start technology, applied in the direction of engine components, engine starting, machine/engine, etc., can solve problems such as difficulty in starting mining dump trucks, achieve high-efficiency low-temperature preheating, save time, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

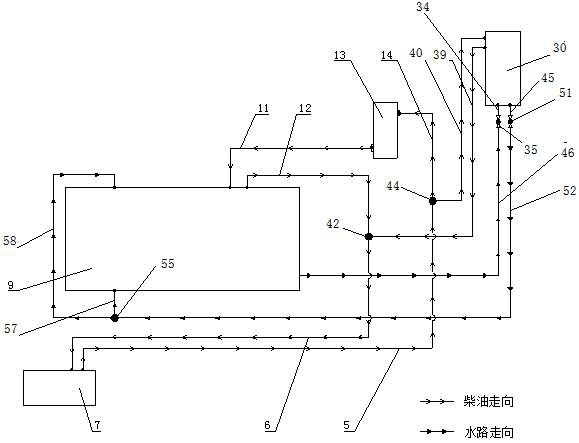

[0037] to combine figure 1 As shown, a mining dump truck cold start system,

[0038] The oil inlet of the engine 9 is connected to the oil inlet pipe II11, the other end of the oil inlet pipe II11 is connected to the oil-water separator 13, the oil inlet of the oil-water separator 13 is connected to the oil inlet pipe III14, and the other end of the oil inlet pipe III14 is connected to the first interface of the three-way joint II44 , the second interface of the tee joint II44 is connected to the oil inlet pipe I5, and the other end of the oil inlet pipe I5 is connected to the fuel tank 7; the oil return port of the engine 9 is connected to the oil return pipe II12, and the other end of the oil return pipe II12 is connected to the first interface of the tee joint I42 , the second interface of the three-way joint I42 is connected to the oil return pipe I6, and the other end of the oil return pipe I6 is connected to the fuel tank 7;

[0039] The oil inlet of the liquid fuel hea...

Embodiment 2

[0047] A kind of mining dump truck cold start method, on the basis of above-mentioned embodiment one, comprises the following steps:

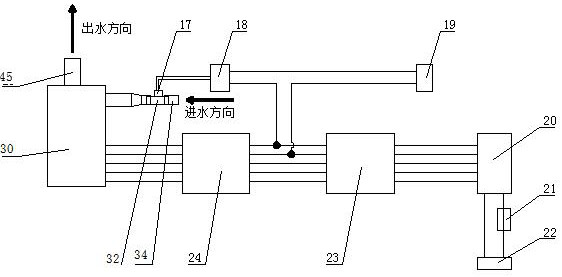

[0048] Turn on the power supply of the whole machine, turn on the rocker switch 20, and the liquid fuel heater 30 starts to work;

[0049] The liquid fuel heater 30 begins to participate in the internal water circulation of the engine. If the coolant temperature does not reach 15°C at this time, the temperature control switch 17 will not work, and the red indicator light 19 will always be on;

[0050] After the temperature of the heated engine coolant reaches above 15°C, the temperature control switch 17 starts to work, so that the working circuit of the red indicator light 19 is disconnected, and the red indicator light 19 goes out at this time, reminding the driver that the engine can be started;

[0051] Close rocker switch 20 after engine starts.

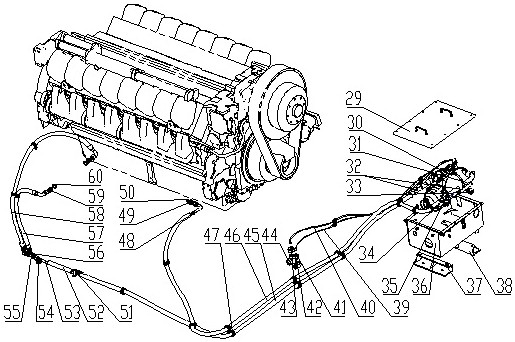

[0052] combine image 3 As shown, the liquid fuel heater 30 is installed in the cold start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com