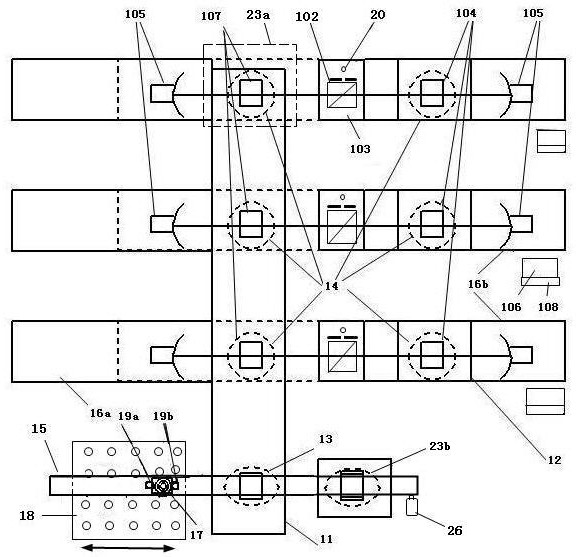

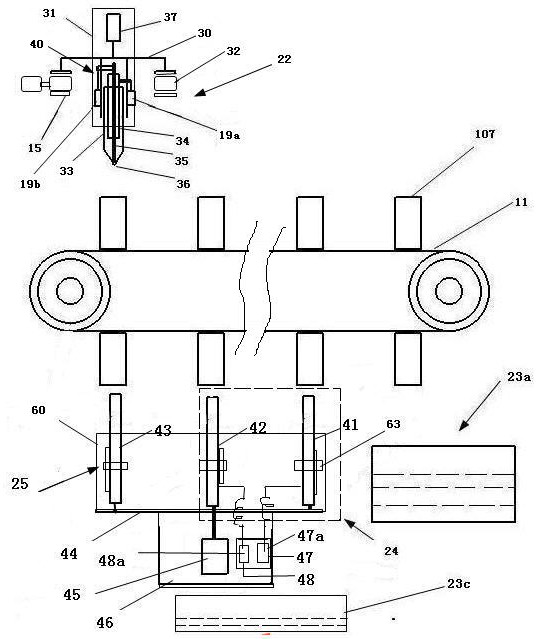

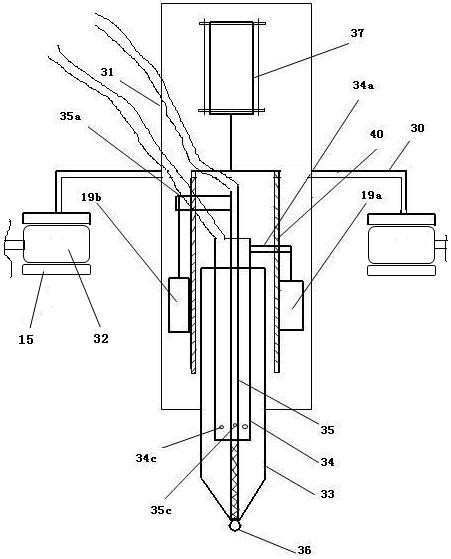

Spectrophotometer for batch detection, and detection method thereof

A spectrophotometer, batch detection technology, applied in measurement devices, analytical materials, color/spectral characteristic measurement, etc. The effect of detecting speed, prolonging service life and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Before the present invention, at first experiment was done to cleaning effect, concrete data is as follows:

[0046] Current routine testing methods

[0047] Wash with water three times, rinse with potassium permanganate solution three times, pour into potassium permanganate solution to measure the absorbance at 545nm, the result is 0.110 (average of five times).

[0048] experimental method

[0049] Potassium permanganate solution concentration: 5✕10 -5 mol / L

[0050] Measurement wavelength: 545nm

[0051] 1. Directly pour potassium permanganate solution into a clean and dry cuvette for testing

[0052] The absorbance value is: 0.110 (average of five times); it shows that the error is very small, and it can be tested directly with a clean cuvette without rinsing;

[0053] 2. Do not rinse or dry after washing with water directly, pour potassium permanganate solution directly into the test

[0054] The absorbance value is: 0.105 (average of five times); the reason ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com