Low-sugar chocolate liquor as well as preparation method and application thereof

A chocolate and slurry technology, applied in the application, cocoa, food science and other directions, can solve the problems of easy blooming, uneven dispersion, and taste impact on the surface, and achieve the improvement of easy blooming, lipophilicity, and sweetness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

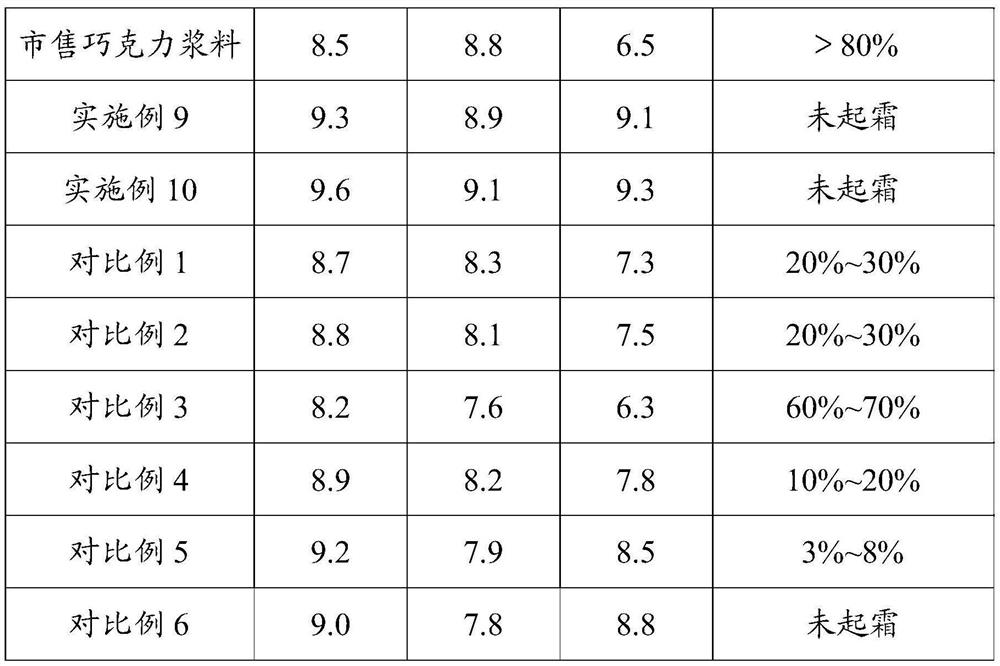

Examples

Embodiment 1

[0021] This embodiment provides a kind of low-sugar type chocolate slurry, the preparation method of this chocolate slurry comprises the following steps:

[0022] S1. Weigh 300g of cocoa pulp, 300g of cocoa butter, 200g of hydrogenated vegetable oil, 200g of vegetable protein, 15g of N-hydroxysuccinimide palmitate, 50g of glyceryl monostearate, and 10g of sweetener, and set aside; The flavoring agent is obtained by mixing disodium glycyrrhizinate and curculigoline in a mass ratio of 2:8; the vegetable protein is a mixture of equal mass ratios of oat protein, soybean protein, almond protein, walnut protein and peanut protein; each raw material All are commercially available products.

[0023] S2. After mixing the above-mentioned hydrogenated vegetable oil, vegetable protein and sweetener, they are mixed with N-hydroxysuccinimide palmitate and glyceryl monostearate, and placed at a temperature of 40°C with a frequency of 20KHz. Frequency ultrasonic treatment to obtain a mixture...

Embodiment 2

[0026] This embodiment provides a kind of low-sugar type chocolate slurry, the preparation method of this chocolate slurry comprises the following steps:

[0027] S1. Weigh 500g of cocoa pulp, 200g of cocoa butter, 100g of hydrogenated vegetable oil, 100g of vegetable protein, 5g of N-hydroxysuccinimide palmitate, 20g of glyceryl monostearate, and 1g of sweetener, and set aside; The flavoring agent is obtained by mixing disodium glycyrrhizinate and curculinous curculin in a mass ratio of 9:1; the vegetable protein is a mixture of oat protein and peanut protein in an equal mass ratio; and all raw materials are commercially available products.

[0028] S2. After mixing the above-mentioned hydrogenated vegetable oil, vegetable protein and sweetener, they are mixed with N-hydroxysuccinimide palmitate and glyceryl monostearate, and placed at a temperature of 60°C with a frequency of 50KHz. Frequency ultrasonic treatment to obtain a mixture.

[0029] S3. At room temperature, mix th...

Embodiment 3

[0031] This embodiment provides a kind of low-sugar type chocolate slurry, the preparation method of this chocolate slurry comprises the following steps:

[0032] S1. Weigh 320g of cocoa pulp, 280g of cocoa butter, 120g of hydrogenated vegetable oil, 120g of vegetable protein, 7g of N-hydroxysuccinimide palmitate, 25g of glyceryl monostearate, and 2g of sweetener, and set aside; The flavoring agent is obtained by mixing disodium glycyrrhizinate and curculinin in a mass ratio of 3:7; the vegetable protein is a mixture of soybean protein, walnut protein and peanut protein in equal mass ratio; all raw materials are commercially available products.

[0033] S2. After mixing the above-mentioned hydrogenated vegetable oil, vegetable protein and sweetener, they are mixed with N-hydroxysuccinimide palmitate and glyceryl monostearate, and placed at a temperature of 45°C at a temperature of 30KHz. Frequency ultrasonic treatment to obtain a mixture.

[0034] S3. At room temperature, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com