Multistage gradient type indirect condensation device and process for treating VOCS waste gas

A condensing device and waste gas technology, which is applied in gas treatment, steam condensation, multi-effect/separation condensation, etc., can solve the problems of refrigeration compressors not running stably, affecting the effect of waste gas condensation treatment, and alarming when equipment is shut down, so as to ensure condensation Governance effect, avoiding unstable operation or damage, and reducing the operating cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

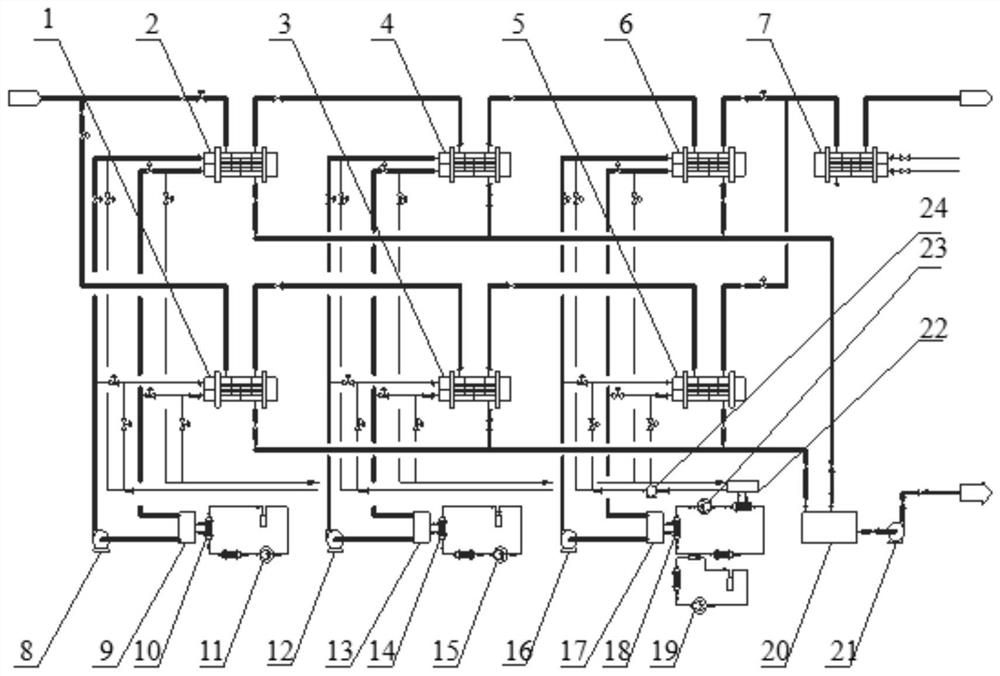

[0037] A VOC processing provided by this embodiment S Multi-stage gradient indirect condensation device of exhaust gas, such as figure 1 As shown, it includes multi-stage exhaust gas condenser A and multi-stage exhaust gas condenser B. Multi-stage exhaust gas condenser A includes one-stage exhaust gas condenser A1, two-stage exhaust gas condenser A3 and three-stage exhaust gas condenser A5, and multi-stage exhaust gas condenser The device B includes a primary exhaust gas condenser B2, a secondary exhaust gas condenser B4, and a tertiary exhaust gas condenser B6, which are connected in series to form exhaust gas condensation channel A and exhaust gas condensation channel B, exhaust gas condensation channel A and exhaust gas condensation Channel B is connected in parallel and then connected to the same exhaust gas collector. The switching of the exhaust gas condensing channel A and the exhaust gas condensing channel B, as well as the switching of condensation and temperature rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com