All-position TIG pipe welding equipment and welding process thereof

A welding equipment, all-position technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of insufficient welding performance and low welding flexibility, and achieve high practicability, welding stability guarantee, welding The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

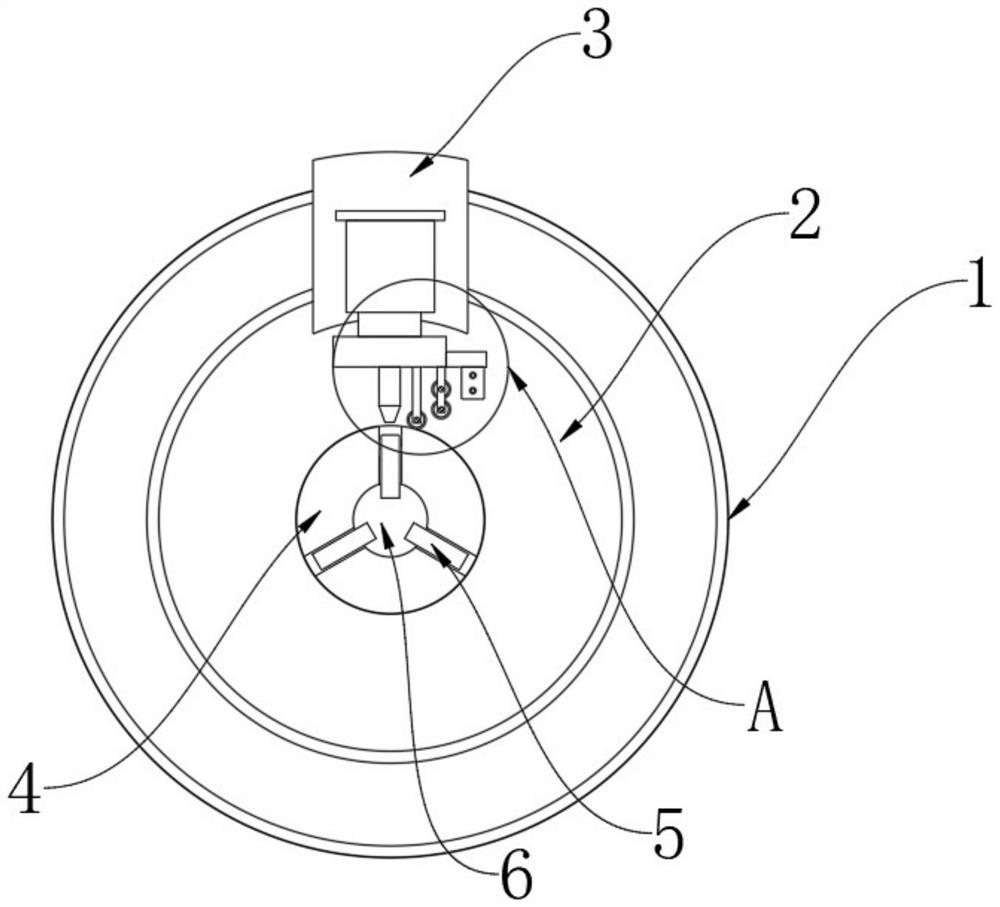

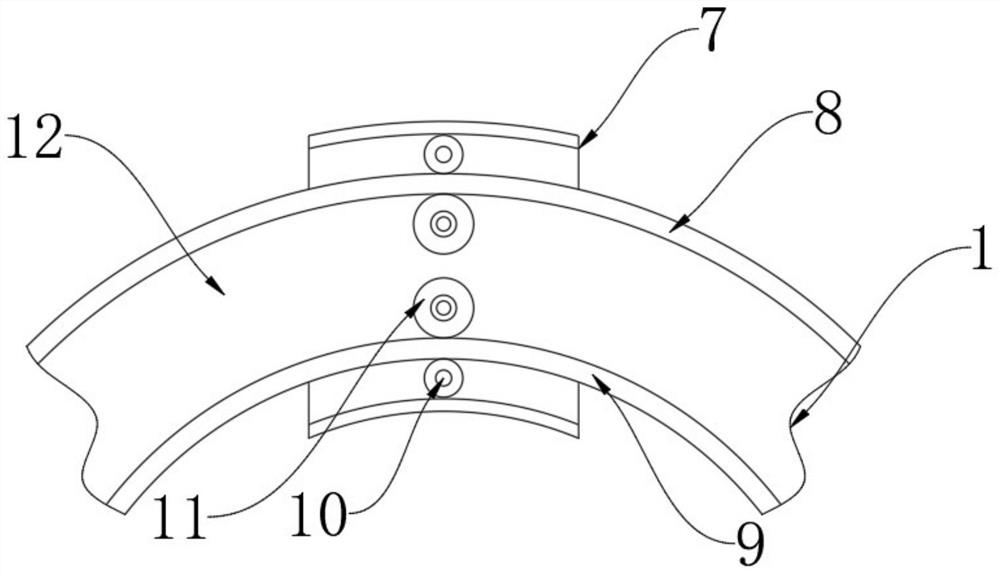

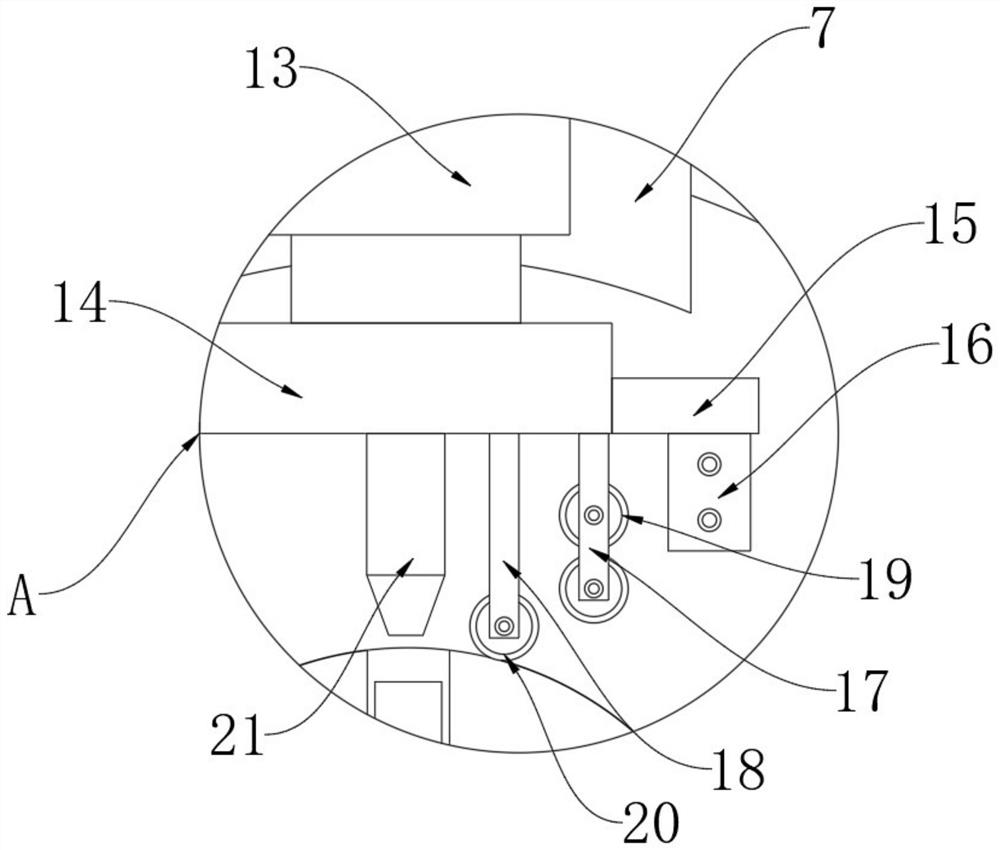

[0026] see Figure 1-3 , an embodiment provided by the present invention: an all-position TIG pipe welding equipment and its welding process, including a welding fixture 1, an internal fixing circular groove 2 is arranged at the middle position inside the welding fixture 1, and the welding fixture 1 is equipped with a rotation adjustment mechanism 3, and the rear end of the inner fixed circular groove 2 is equipped with a three-jaw chuck main body 4, and the front end of the three-jaw chuck main body 4 is equipped with a limited locking tooth 5, and the middle position inside the three-jaw chuck main body 4 A central fixing hole 6 is provided at the center, the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com