Intelligent full-automatic slitting device

A fully automatic, conveying device technology, applied in metal processing, etc., can solve the problems of high management cost, difficult sanitation control, high labor intensity, etc., and achieve the effects of reducing costs, improving cutting efficiency, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

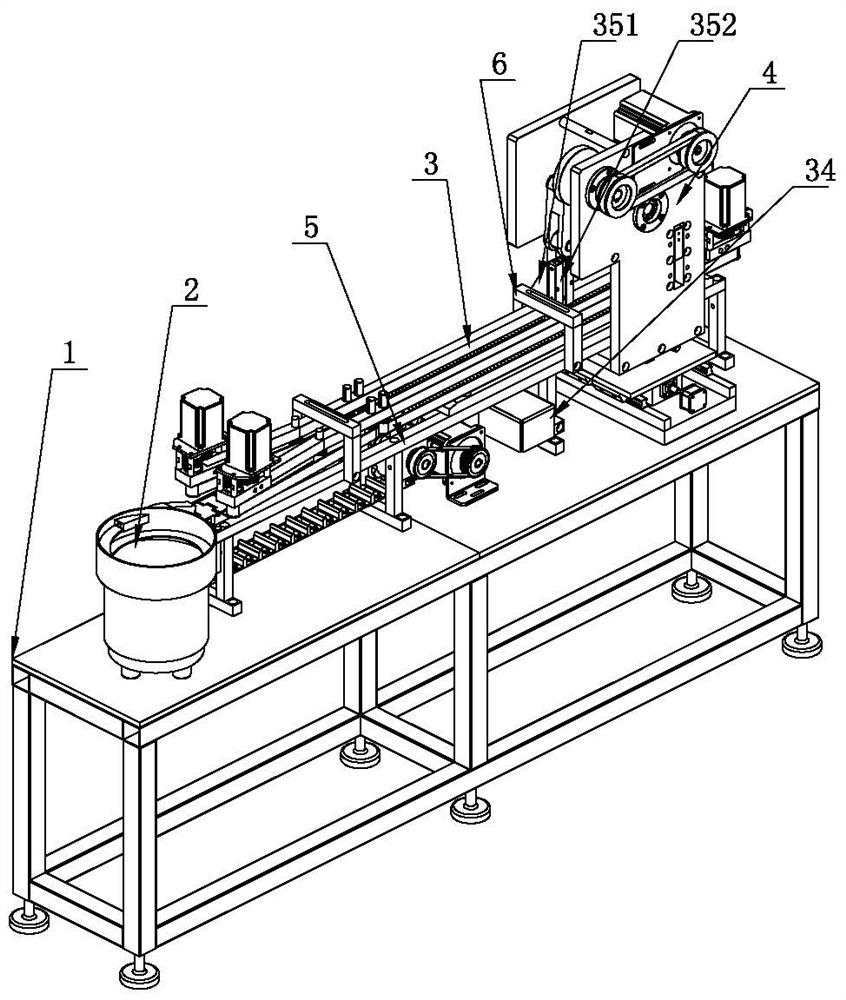

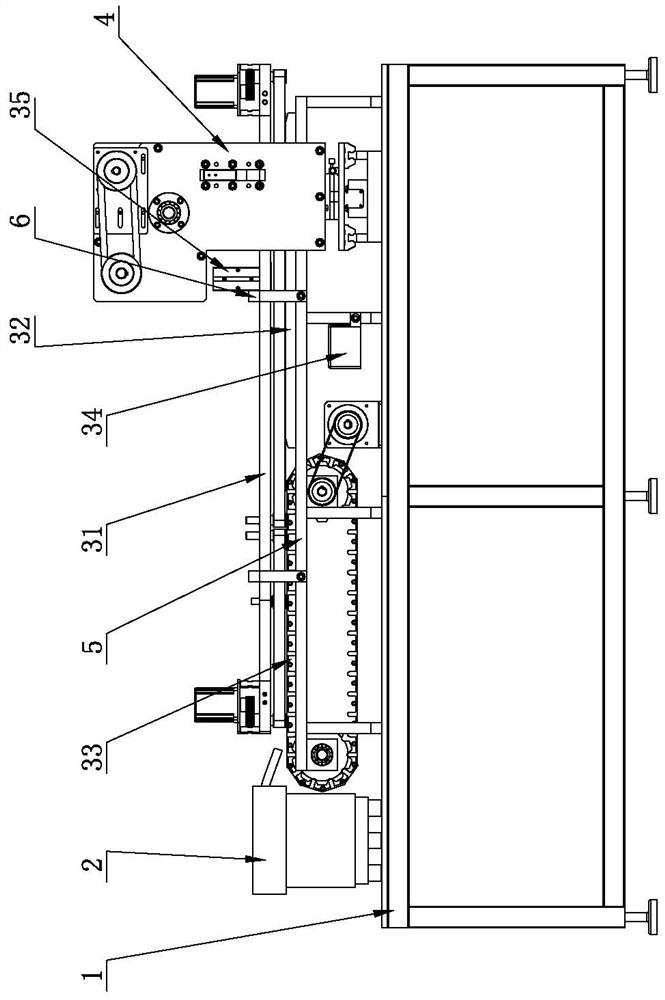

[0025] Such as Figure 1-9 A kind of intelligent full-automatic slitting device shown, it is used for the slitting of betel nut 7, comprises the feeding device 2 that is arranged on the frame 1, clamping conveying device 3 and slitting device 4; A transmission frame 5 is installed, and the clamping and conveying device 3 is installed on the transmission frame 5. The feeding device 2 is used to send the betel nut 7 to be processed to the clamping and conveying device 3, and the clamping and conveying device 3 is used to adjust the betel nut to be processed. 7 in the conveying direction, realize conveying one by one, and send the betel nut 7 to the cutting device 4 for cutting, and the cutting device 4 is used to cut the betel nut 7 to be processed to obtain the betel nut 7 after cutting.

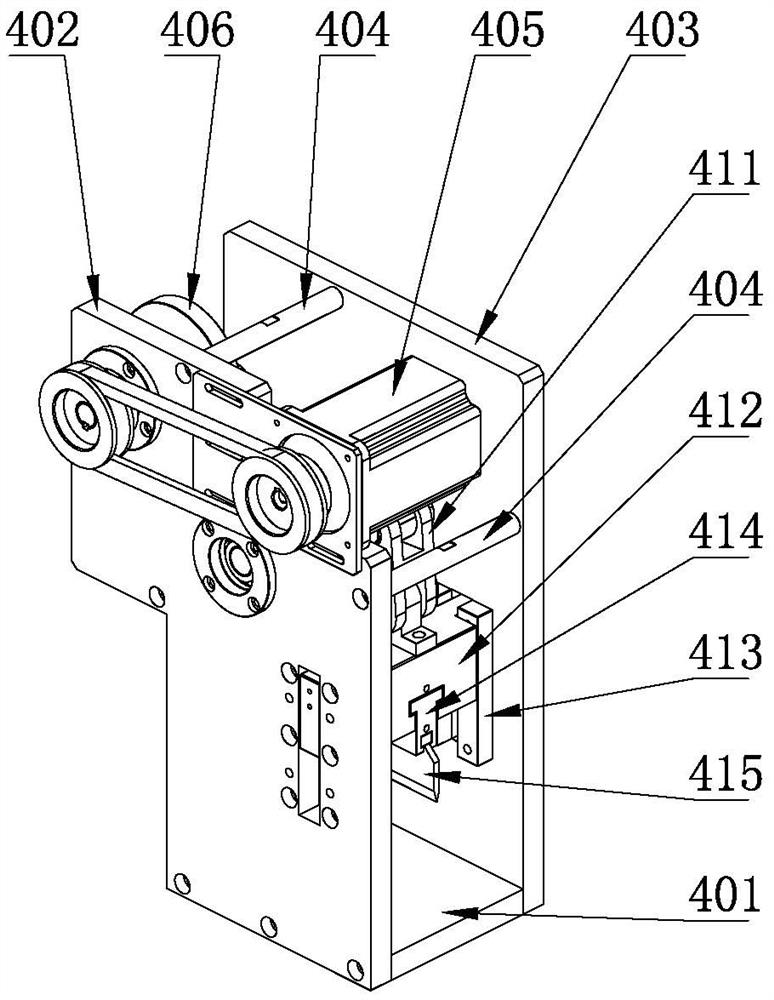

[0026]Slitting device 4 comprises connecting plate 401 installed on the fine-tuning movable base plate, connecting plate 401 connects the bottom of a pair of side plates 402,403, links to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com