Coaxial electric drive axle power assembly with disconnecting mechanism

A technology of electric drive and powertrain, which is applied in the direction of electric power device, power device, control device, etc., can solve the problems that affect the battery life of the whole vehicle, unfavorable light weight of the whole vehicle, and large power train volume, etc. Vehicle endurance, beneficial to lightweight, and the effect of reducing vehicle energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

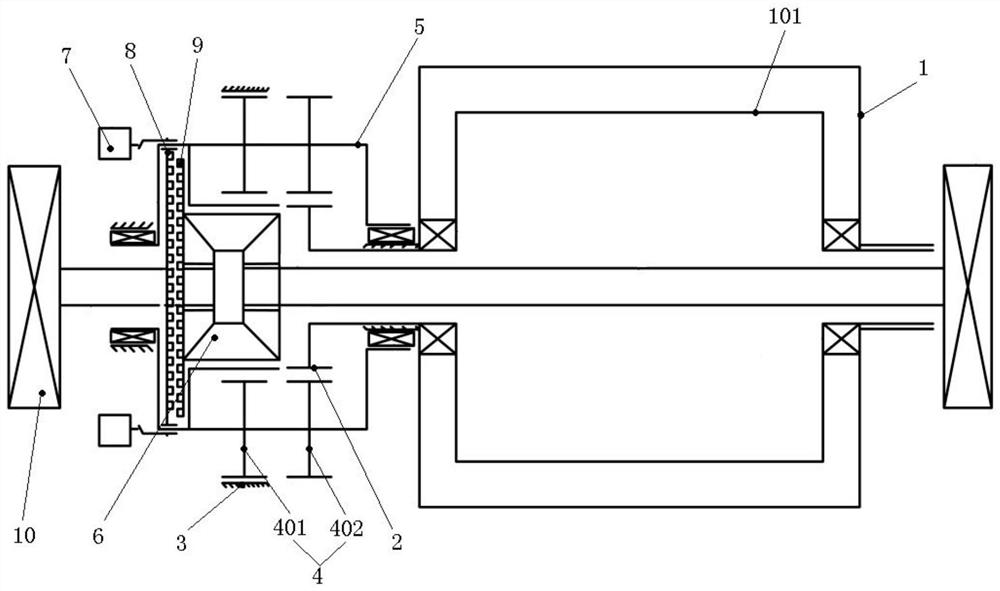

[0015] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure, a coaxial electric drive axle power assembly with a disconnection mechanism in this embodiment includes a motor 1, a sun gear 2, a fixed outer ring gear 3, and a planetary gear 4. The differential case 5, the differential gear train 6 and the power disconnection mechanism, the sun gear 2 is mounted on the rotor shaft 101 of the motor 1, and the planetary gear 4 is mounted on the on the differential case 5, and the planetary gear 4 can drive the differential case 5 to rotate synchronously around the rotation axis of the sun gear 2, the sun gear 2, the planetary gear 4 1. The differential case 5 and the fixed outer ring gear 3 form a planetary gear train, the power provided by the motor 1 is input into the planetary gear train through the sun gear 2, and is transmitted by the differential case Body 5 output; the power input end of the power disconnection mechanism is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com