Adhesion weakening and plasma high-energy actuator combined deicing device and method

A plasma and exciter technology, applied in deicing devices, transportation and packaging, aircraft parts, etc., can solve the problems of large energy consumption, heavy weight, complex structure, etc., and achieve simple devices, high manufacturing costs, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

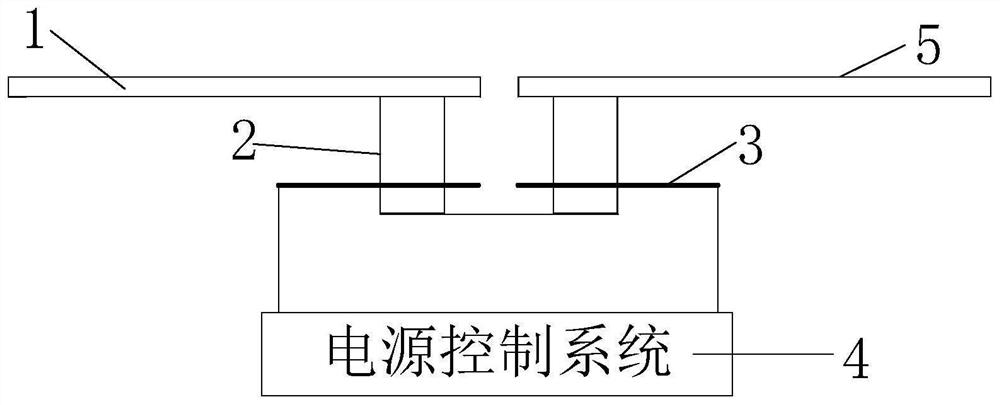

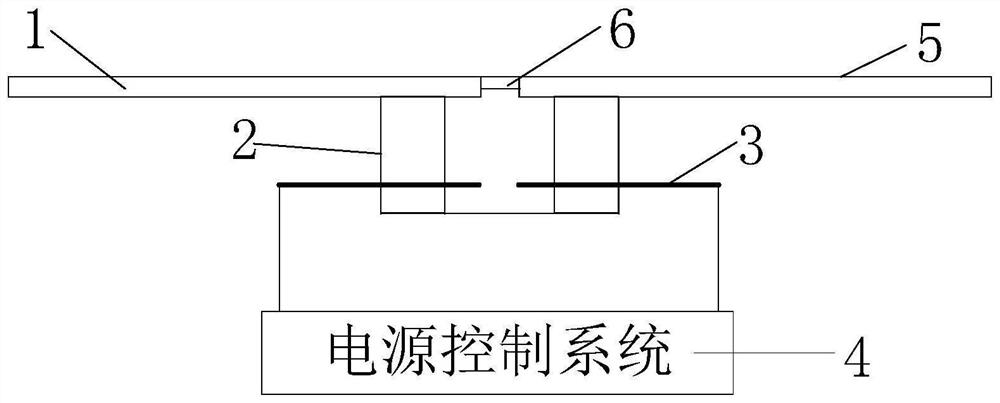

[0033] The anti-icing device combined with adhesion weakening and plasma high-energy actuator includes a device 5 for weakening adhesion, a plasma high-energy actuator and a power control system 4 .

[0034] A device 5 for weakening adhesion is provided on the surface 1 with deicing requirements. The device 5 for reducing adhesion in the present invention may be a low-adhesion material arranged on a surface requiring deicing. The low-adhesion material can be provided on the surface requiring deicing by etching, coating and other methods as required. Low-adhesion materials need to be selected according to factors such as surface substrates, such as polytetrafluoroethylene, polyvinylidene fluoride, polysiloxane-based viscoelastic materials, polydimethylsiloxane, etc. The device 5 for weakening the adhesion described in the present invention can also be a heating device (not shown in the figure). Heating devices include traditional electric heating devices, integrated electric ...

Embodiment 2

[0039] The anti-icing device combined with adhesion weakening and plasma high-energy actuator includes a device 5 for weakening adhesion, a plasma high-energy actuator and a power control system 4 .

[0040] A device 5 for weakening adhesion is provided on the surface 1 with deicing requirements. The device 5 for reducing adhesion in the present invention may be a low-adhesion material arranged on a surface requiring deicing. The low-adhesion material can be provided on the surface requiring deicing by etching, coating and other methods as required. Low-adhesion materials need to be selected according to factors such as surface substrates, such as polytetrafluoroethylene, polyvinylidene fluoride, polysiloxane-based viscoelastic materials, polydimethylsiloxane, etc. The device 5 for weakening the adhesion described in the present invention can also be a heating device (not shown in the figure). Heating devices include traditional electric heating devices, integrated electric ...

Embodiment 3

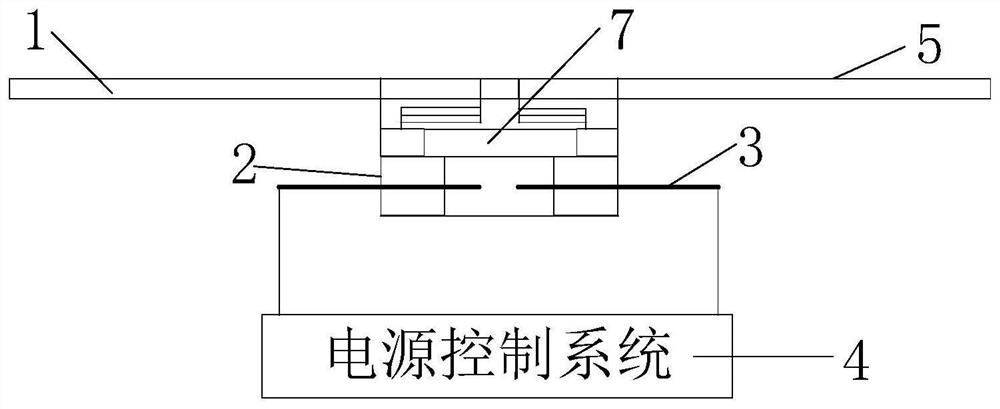

[0045] A high-energy plasma exciter includes a main casing 2, an electrode 3 and an actuating mechanism 7, the electrode 3 is arranged on the main casing 2, one end of the electrode 3 extends into the inner cavity of the main casing 2, and the outlet of the cavity An actuating mechanism is arranged on the top.

[0046] For the sealing and waterproofing problem of the plasma high-energy exciter in severe icing weather, in this embodiment, a micro-piston actuating mechanism 7 is arranged at the exit of the plasma high-energy exciter to seal the exit.

[0047] refer to Figure 4 , a specific implementation of the miniature piston actuator 7 is given. like Figure 4 As shown, the actuating mechanism 7 includes a top case 7.1, a spring 7.2, a piston 7.3, an insulating washer 7.4, an insulating washer 7.5 and a buffer washer 7.6, the top case 7.1 is arranged above the main case 2, and the top case 7.1 A piston 7.3 is arranged in the cavity, the bottom of the piston 7.3 is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com