Railway excrement and urine wastewater treatment system

A waste water treatment system, feces and urine technology, applied in multi-stage water treatment, water/sewage treatment, toilet black water treatment, etc., can solve the problem of reducing the decomposition efficiency of biochemical systems, the application restrictions of microbial fermentation and decomposition of feces and urine waste water, and long-chain organic matter It is not easy to decompose and other problems to achieve the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

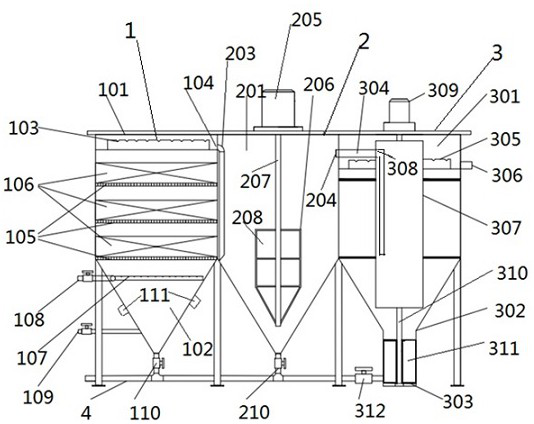

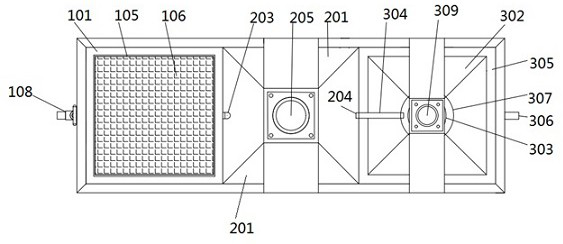

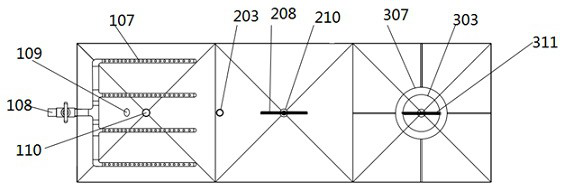

[0019] Below in conjunction with accompanying drawing, the present invention will be further described by preferred embodiment:

[0020] Such as Figure 1 to Figure 3 Shown, this railway waste water treatment system comprises iron-carbon micro-electrolysis reactor 1, ammonium magnesium phosphate reactor 2 and ammonium magnesium phosphate solid-liquid separation reactor 3, and iron-carbon micro-electrolysis reactor 1 comprises the first rectangular parallelepiped The upper hopper 101 and the conical first lower hopper 102 are connected at the mouth. The inner side of the top of the first upper hopper 101 is provided with a zigzag first water receiving weir groove 103, the first water receiving weir groove 103 is generally set at 15 to 25 cm from the upper edge of the first upper hopper 101, and the first water receiving weir groove 103 A first water outlet 104 is provided, and a three-layer load-bearing grid 105 (generally at least two layers of weighing grids) is installed be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com