A method for wastewater treatment in gallic acid production

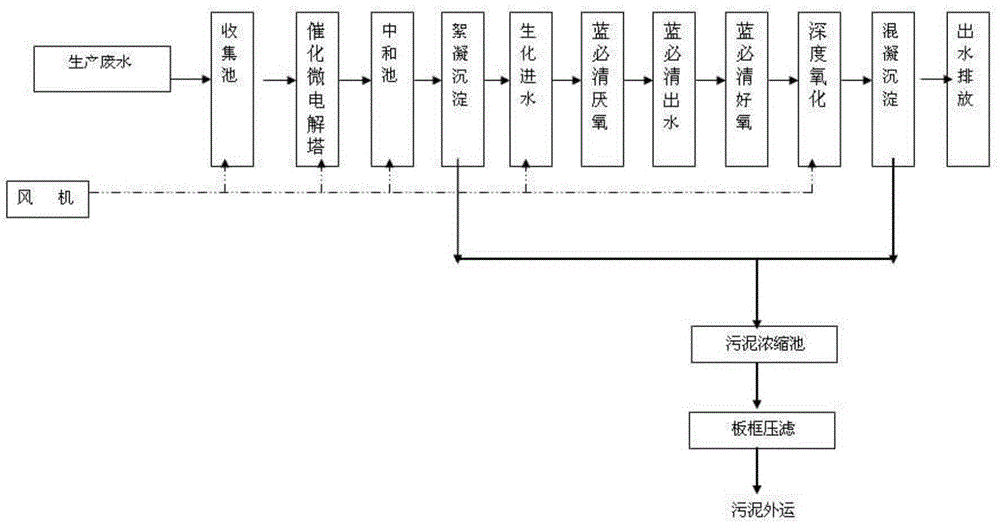

A technology for gallic acid and wastewater treatment, applied in the direction of biological water/sewage treatment, water/sewage treatment, sustainable biological treatment, etc., can solve the problems of high cost, large environmental pollution, and complicated wastewater treatment process, and achieve low loss, The effect of low operating costs, high process stability and volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

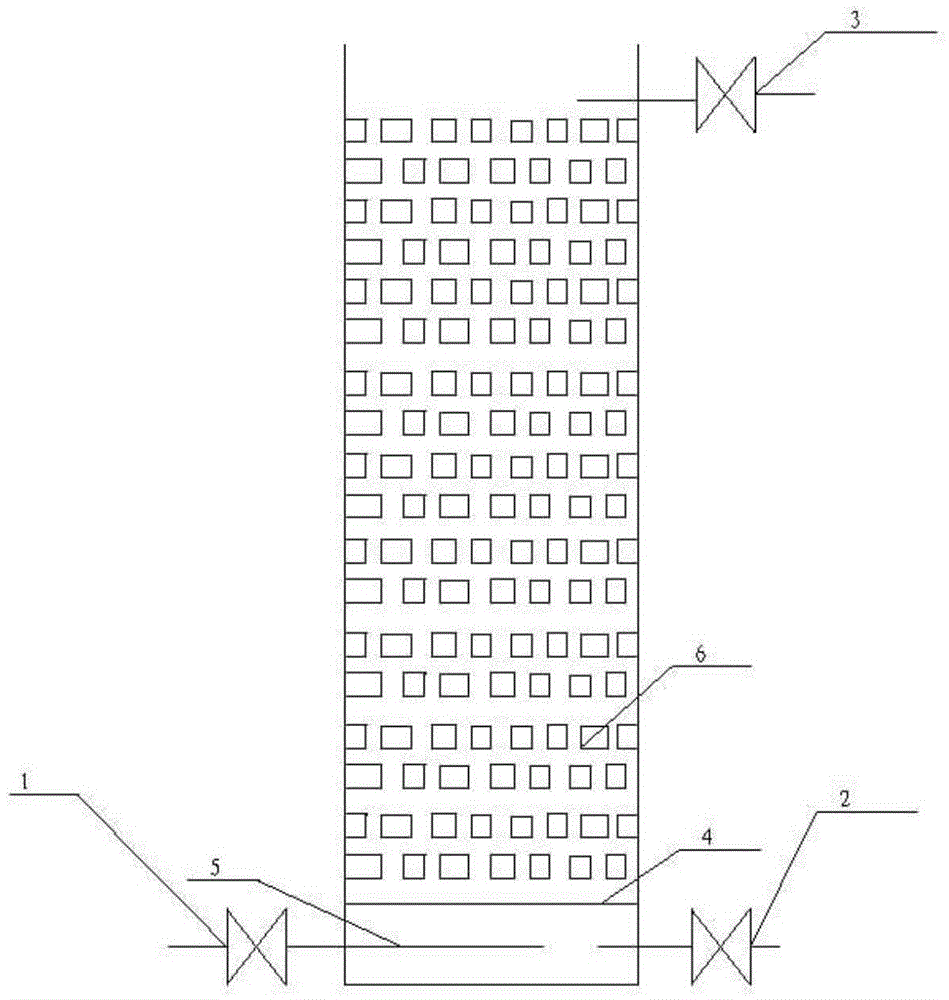

[0066] (1) The waste water produced by gallic acid is processed through a catalytic micro-electrolysis tower device and a flocculation precipitation process: get 500 milliliters of raw water and dilute it to 5 liters, add alkali to adjust the pH to 5, add 30 grams of hydrogen peroxide (content is 27%), and use a flow rate of 200 Milliliters per hour are pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 10 milliliters of polyacrylamide (0.5%) is added to flocculate and precipitate.

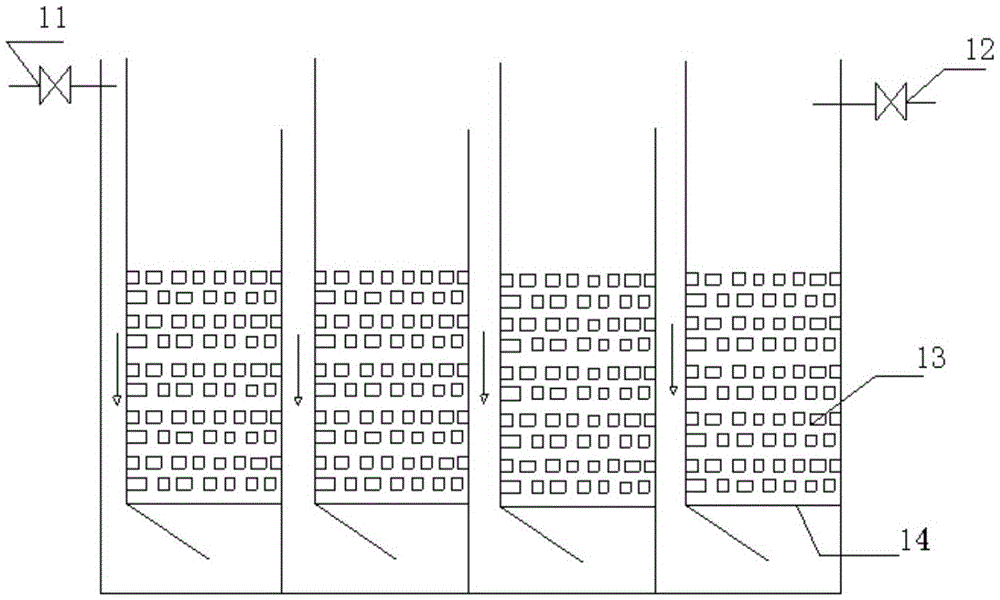

[0067] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite strains (acclimated and lifted) anaerobic biological device stay for 48 hours.

[0068] (3) The effluen...

Embodiment 2

[0072] (1) The waste water produced by gallic acid is processed through catalytic micro-electrolysis tower device and flocculation precipitation process: take 500 milliliters of raw water and dilute to 5 liters, add alkali to adjust pH to 5, add 45 grams of hydrogen peroxide (content is 27%), with flow rate 200 ml / hour is pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 15 milliliters of polyacrylamide (0.5%) is added to flocculate and precipitate.

[0073] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite strains (acclimated and lifted) anaerobic biological device stays for 60 hours.

[0074] (3) The effluent after anaerobic treatment of ...

Embodiment 3

[0078] (1) The waste water produced by gallic acid is processed through catalytic micro-electrolysis tower device and flocculation precipitation process: take 500 milliliters of raw water and dilute to 5 liters, add alkali to adjust pH to 5, add 60 grams of hydrogen peroxide (content is 27%), with flow rate 200 milliliters / hour is pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 20 milliliters of polyacrylamide (content is 0.5%) is added to flocculate and precipitate.

[0079] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite bacteria (acclimated and lifted) anaerobic biological device stays for 72 hours.

[0080] (3) The effluent of Lanbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com