Cast rolling method for restraining center segregation of Cu element in high-alloy-content Al-Cu alloy through nano TiC particle adding

An al-cu, alloy technology, applied in the field of aluminum alloy sheet preparation, can solve the problems of complex casting and rolling process, energy consumption, different acquisition methods, etc., and achieve the effect of improving strong plasticity and improving center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation of the nano-TiC master alloy comprises the following steps:

[0044] a) Take graphite sheet, titanium powder and aluminum powder in proportion and mix and ball mill for 24-36h;

[0045] Wherein, the molar ratio of the graphite sheet and the titanium powder is 1:1 and the total mass percentage of the graphite sheet and the titanium powder is 20-40%;

[0046] b) The mixed alloy powder of graphite sheet, titanium powder and aluminum powder is made into a cylindrical compact, and placed in a graphite mold, heated to 850-950°C in a vacuum environment, kept for 10 minutes and then cooled to room temperature to obtain nano-TiC aluminum base master alloy.

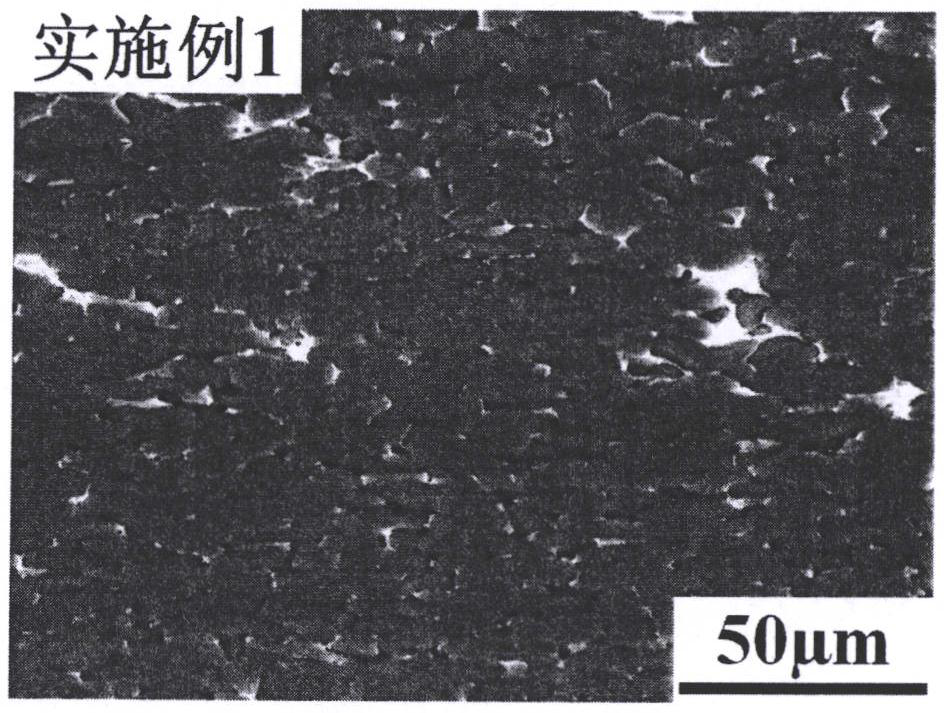

Embodiment 1

[0074] The specific preparation method of the Al-Cu alloy plate after adding 0.2% TiC particles by mass percentage includes the following steps:

[0075] Step 1. Prepare Al-Cu alloy melt and add nano-TiC particles:

[0076] 1) Prepare materials according to the content of each alloy component and place them in a melting furnace, raise the temperature to 800-850°C to obtain molten Al-Cu alloy liquid, and keep it warm for 10-20min;

[0077] 2) Add nano-TiC aluminum-based master alloy into the molten Al-Cu alloy liquid, perform ultrasonic treatment after mechanical stirring for 1-2min;

[0078] 3) Adjust the temperature of the melt to 695-705°C, let it stand for 3-5 minutes, then add a slag remover to the melt, stir for 1-2 minutes, and then remove the slag;

[0079] Wherein, the mass fraction of nano-TiC in the nano-TiC aluminum-based master alloy is 20-40%, and by controlling the quality of the nano-TiC aluminum-based master alloy, the mass fraction of the nano-TiC particles i...

Embodiment 2

[0088] The specific preparation method of the Al-Cu alloy plate after adding 0.5% TiC particles by mass percentage includes the following steps:

[0089] Step 1. Prepare Al-Cu alloy melt and add nano-TiC particles:

[0090] 1) Prepare materials according to the content of each alloy component and place them in a melting furnace, raise the temperature to 800-850°C to obtain molten Al-Cu alloy liquid, and keep it warm for 10-20min;

[0091] 2) Add nano-TiC aluminum-based master alloy into the molten Al-Cu alloy liquid, perform ultrasonic treatment after mechanical stirring for 1-2min;

[0092] 3) Adjust the temperature of the melt to 695-705°C, let it stand for 3-5 minutes, then add a slag remover to the melt, stir for 1-2 minutes, and then remove the slag;

[0093] Wherein, the mass fraction of nano-TiC in the nano-TiC aluminum-based master alloy is 20-40%, and by controlling the quality of the nano-TiC aluminum-based master alloy, the mass fraction of the nano-TiC particles i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com