Vertical barrier structure and method of prefabricated assembled bentonite material for underground pollution control

A prefabricated, bentonite technology, used in infrastructure engineering, protection devices, buildings, etc., can solve the problems of difficult to control leakage at lap joints, weak pollutant diffusion capacity, etc., to achieve convenient construction, good integrity and reliability. , the effect of high content of bentonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

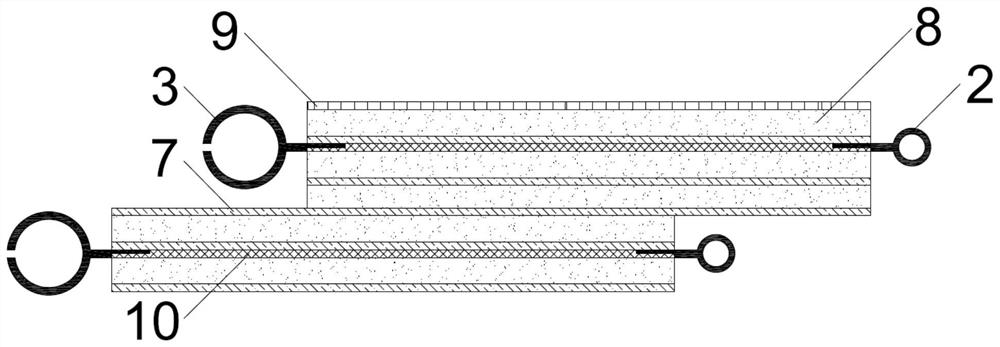

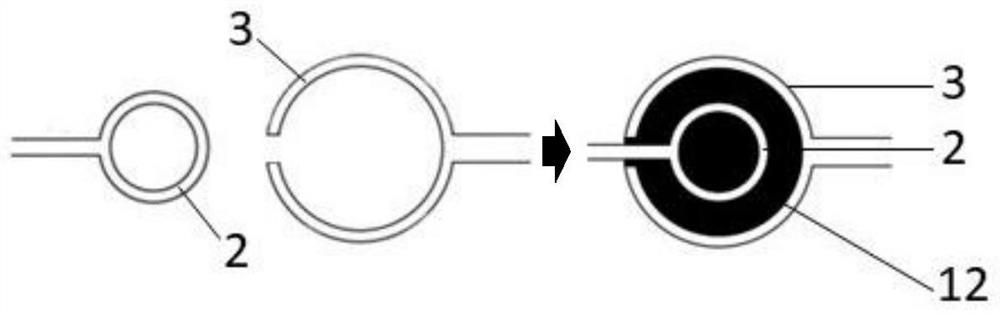

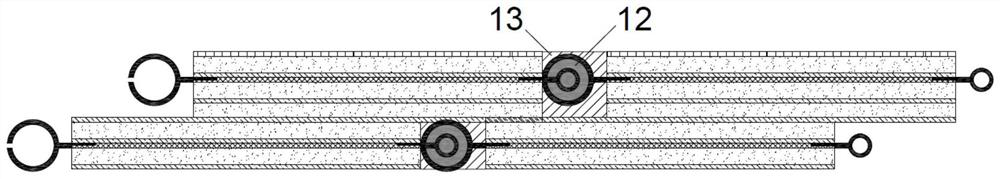

[0048] Such as Figure 4 As shown, the prefabricated bentonite material vertical barrier structure is set in the soil body, the soil body includes the polluted aquifer 4, the unpolluted aquifer 5 and the aquifer 6, and the prefabricated assembled bentonite material vertical barrier structure includes the polluted aquifer 4 and at least one prefabricated barrier wall 1 between the unpolluted aquifer 5, and a trench is opened between the polluted aquifer 4 and the unpolluted aquifer 5, and the trench extends into the aquifer 6 and embedded The depth of the water-resistant layer 6 is not less than 1m. The prefabricated barrier wall 1 is placed in the trench and the lower part is embedded in the water-resistant layer 6 (the suspended structure only needs to reach a certain depth). A stable upstream water level and a downstream water level are formed, and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com