Muck drainage pond structure and pressure difference electromagnetic field coupling drainage method for muck

A drainage pond and muck technology, which is applied in drainage structures, soil protection, water/sewage treatment, etc., can solve the problems of high investment cost and operating cost, no space for placing the whole set of equipment, and limited construction site space. Enhanced effect, less clogging, faster drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

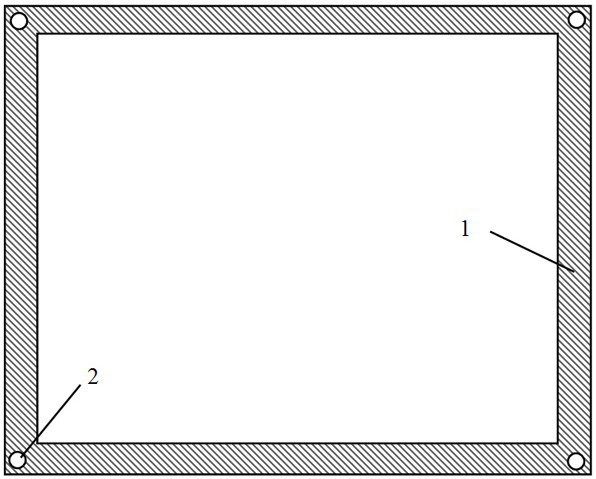

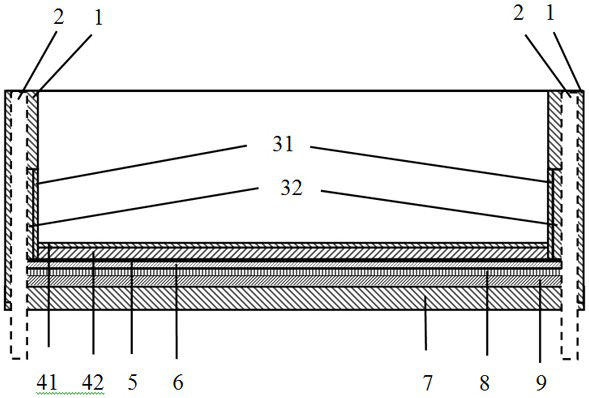

[0042] Such as Figure 1-2 As shown, the muck drainage pond structure of the present invention includes a muck drainage pond 1 and an electroosmosis control instrument. A water collection well 2, the water collection well 2 is vertically arranged. The well wall of the water collection well 2 is formed by placing ecological sand-based permeable bricks in the direction of the reverse filter layer. The side wall between the lower inner cavity of the muck drainage pond 1 and the water collection well is made of permeable material; the side wall between the lower inner cavity of the muck drainage pond 1 and the water collection well 2 includes a permeable layer I31 and Water-permeable layer II32 and water-permeable layer I31 are located inside water-permeable layer II32. Water-permeable layer I31 is made of micronano-scale water-permeable resin sand, and water-permeable l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com