A fire-proof decoration integrated fire-proof isolation belt

A technology for fire isolation belt and decoration, applied in fire prevention, construction, building components, etc., can solve the problems of fire isolation belt fire resistance that needs to be improved, rock wool cannot be directly bonded to the wall, increased construction period and construction difficulty, etc. , to improve the environmental quality of products, increase the risk of fire spread, and shorten the construction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

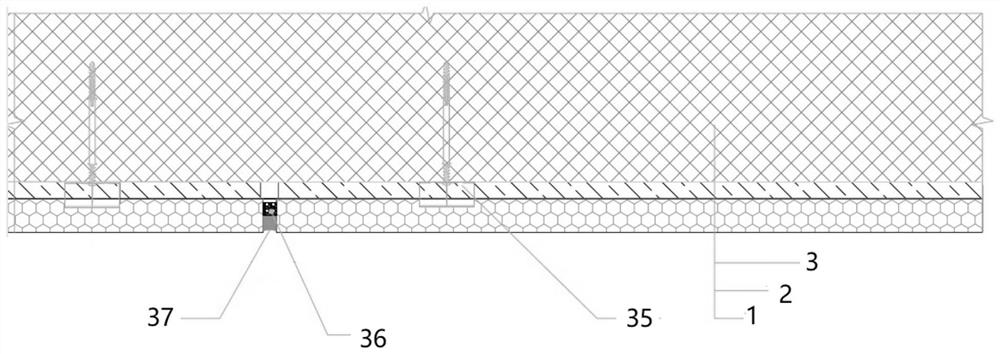

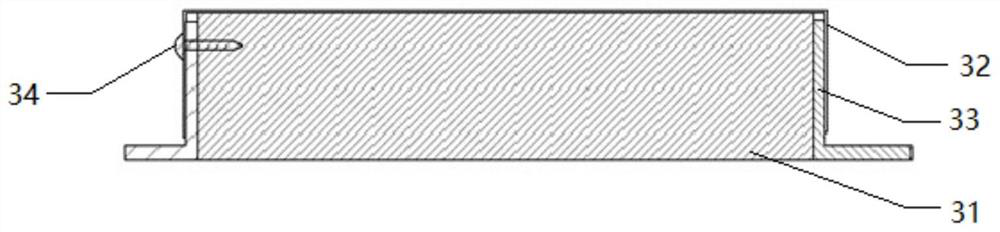

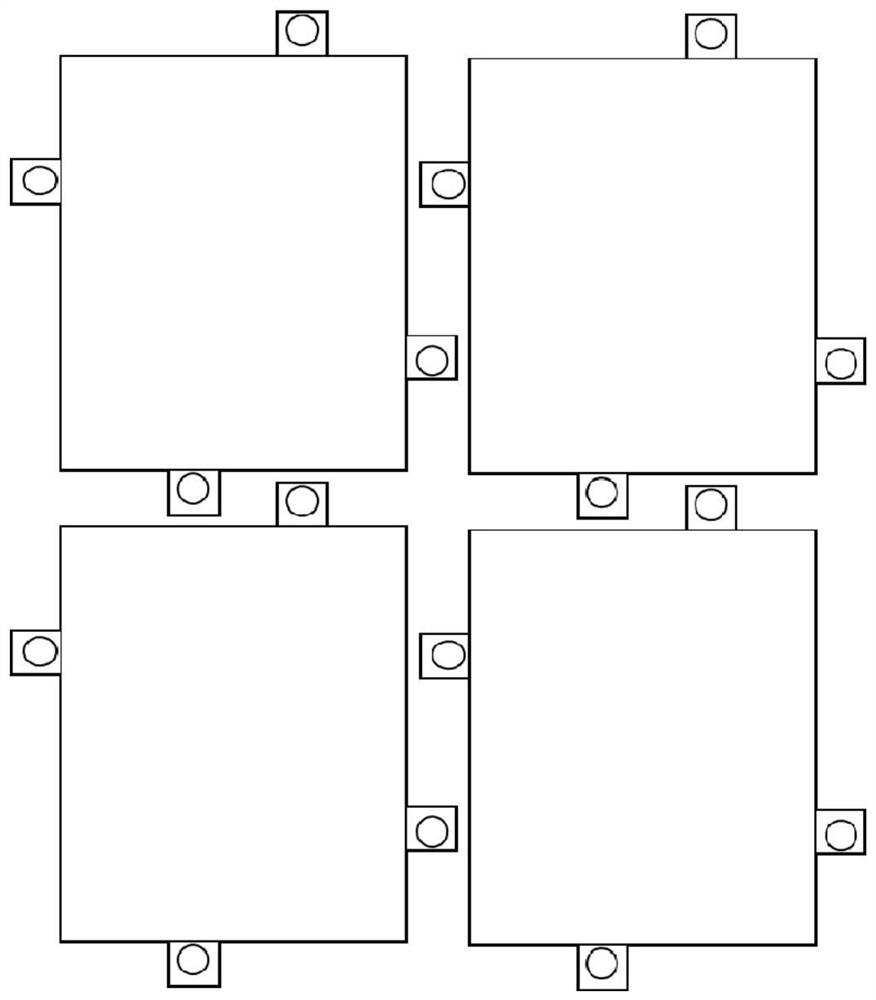

[0116] A new type of fire-proof decorative integrated fire isolation belt, which is laid on the building exterior wall 1, corresponding to the height area of the floor slab between floors, is a belt around the wall, and the upper and lower ends are connected with thermal insulation materials. The fire isolation belt is formed by the building exterior wall 1 includes a 10mm bonded mortar layer 2 and a 25mm fireproof insulation board layer 3 in sequence. The bonding mortar layer 2 covers 100% of the building exterior wall 1 in the area where the fire isolation zone is located. The fireproof insulation boards are closely arranged in the fireproof insulation board layer 3. The fireproof insulation boards in each row are arranged at the same height, and the fireproof insulation boards in two adjacent rows are arranged in alignment. The gap between adjacent fireproof insulation boards is 8mm, and the bottom of the gap is laid The plastic caulking strip 36 seals the gap with weathe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com