Assembly-type ardealite-concrete combined wallboard and preparation and assembly methods

A technology of concrete and phosphogypsum, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of natural resources and environmental burden, low production efficiency of prefabricated wall panels, low degree of industrialization, etc., and achieve good collaborative work performance, improvement of artificial working environment, and high overall seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

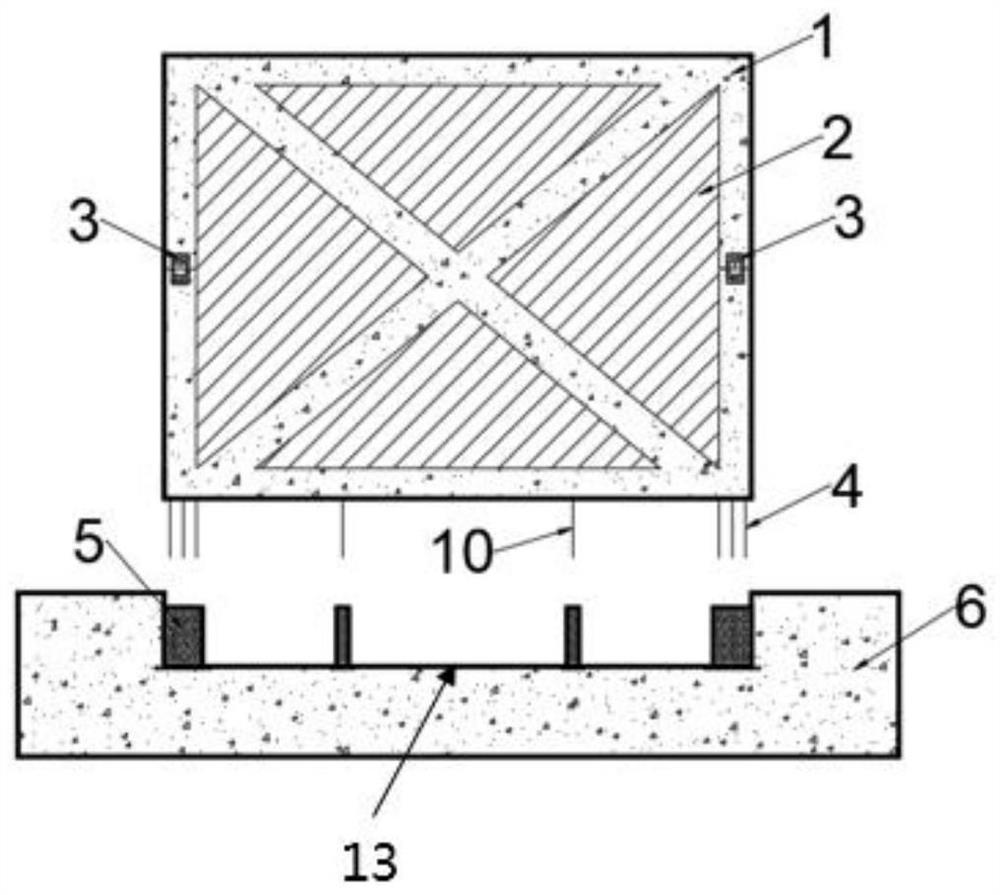

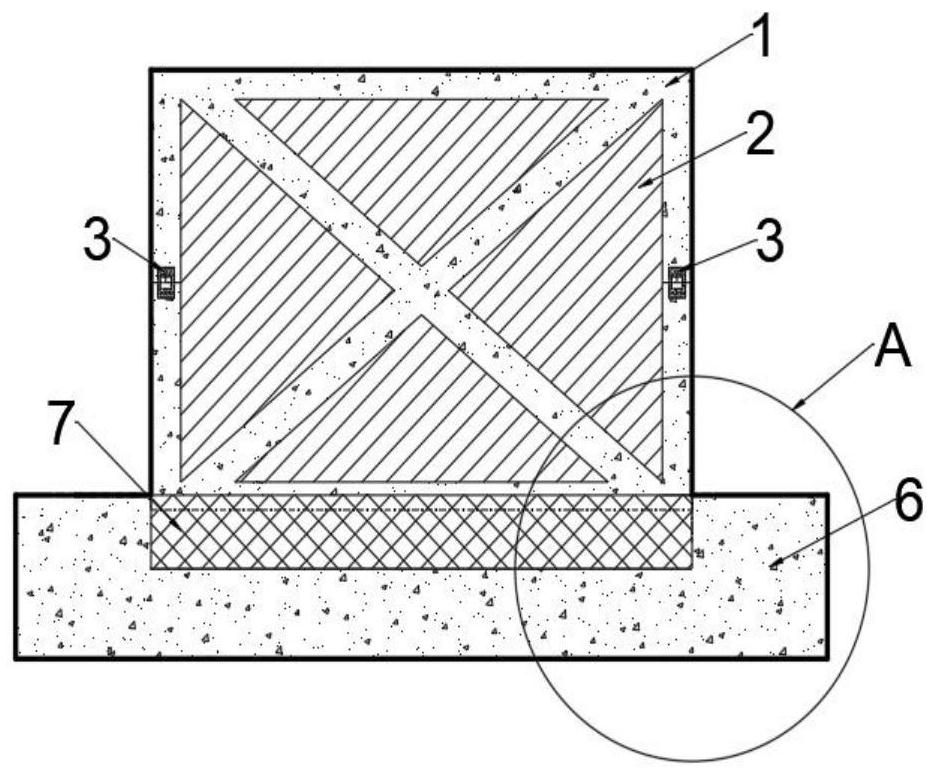

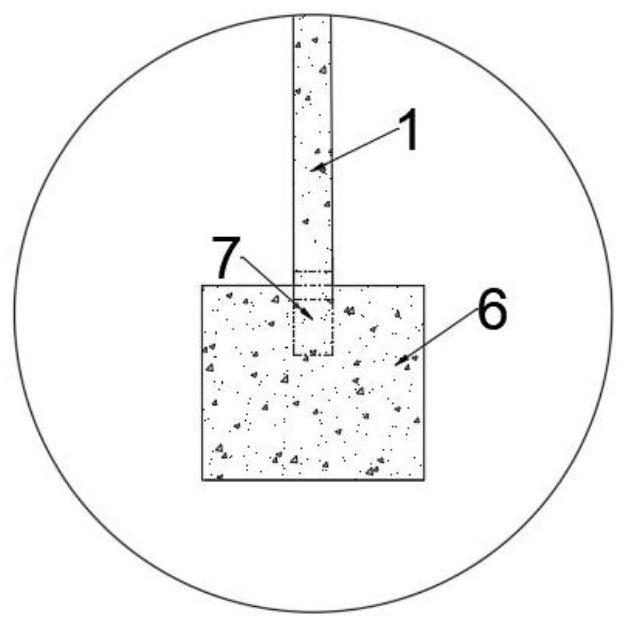

[0044] Example 1. A prefabricated phosphogypsum-concrete composite wallboard, constituted as Figure 1-6 As shown, it includes a concrete frame 1 and a prefabricated concrete ground beam 6; the top beam and the bottom beam of the concrete frame 1 are all embedded with frame beam steel bars 11, and the two column beams of the concrete frame 1 are all buried with frame column steel bars 4 , the bottom end of the frame column reinforcement 4 also protrudes from the bottom beam of the concrete frame 1, and the concrete frame 1 is filled with phosphogypsum-based composite cementitious filler 2; the precast concrete ground beam 6 is provided with a rough inner surface The groove 13 is provided with a pre-embedded steel cylinder 5; the frame column steel bar 4 protruding from the bottom beam of the concrete frame 1 can be inserted into the corresponding pre-embedded steel cylinder 5. At this time, the bottom beam part of the concrete frame 1 sinking into the groove 13; the groove 13...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap