Novel composite drying method of camellia oleifera fruits

A technology for compound drying and camellia oleifera, which is applied in the direction of drying solid materials, drying gas arrangement, botanical equipment and methods, etc., can solve the problems of long drying time, easy to be affected by weather, high labor cost and so on, and achieve the reduction of heap The effect of storing rotten fruit rate, avoiding overheating phenomenon, and reducing rotten fruit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

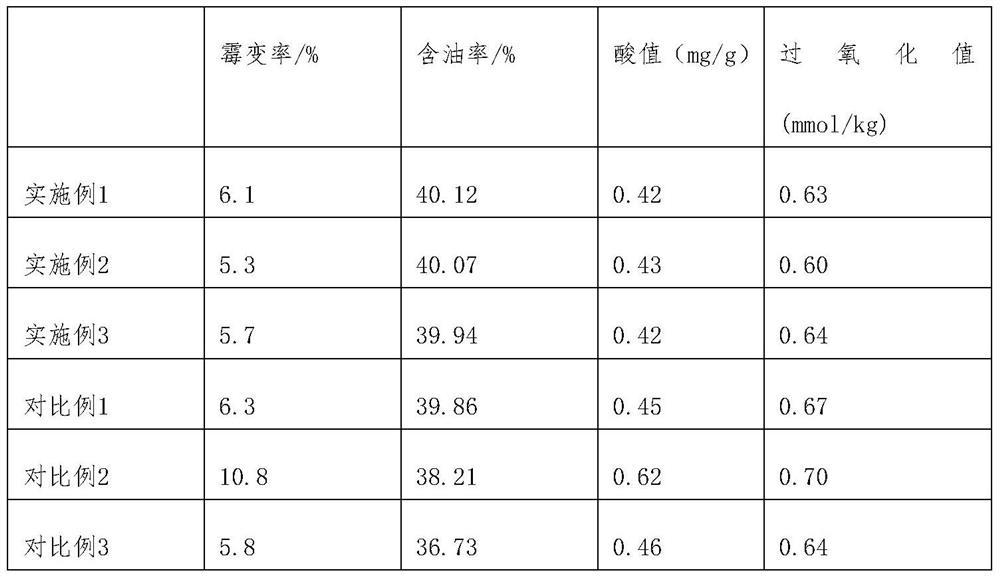

Examples

Embodiment 1

[0028] A novel compound drying method for camellia oleifera fruit, including the following steps:

[0029] (1) Stack the picked fresh camellia oleifera fruit in the stacking room, and spread a layer of 3-4cm heat dissipation compound on the ground before stacking the camellia oleifera fruit; then stack the camellia oleifera fruit with a thickness of 5-6cm;

[0030] (2) After stacking the camellia fruit for 1-2 days, spray an ethephon solution with a concentration of 0.1% on the surface of the camellia fruit, and continue to stack it for 5 days after spraying;

[0031] (3) Add composite sand to the frying machine. After heating the composite sand at 35-40℃, keep the temperature of the composite sand, add the camellia fruit and stir continuously for 10 hours. After cooling, send it to the peeling machine for peeling treatment. Obtain Camellia seeds;

[0032] (4) Put the oil-tea camellia seeds into the osmotic treatment solution, treat them under a vacuum of 0.06-0.08kPa for 30 minutes, ...

Embodiment 2

[0038] A novel compound drying method for camellia oleifera fruit, including the following steps:

[0039] (1) Stack the picked fresh camellia oleifera fruit in the stacking room, and spread a layer of 3-4cm heat dissipation compound on the ground before stacking the camellia oleifera fruit; then stack the camellia oleifera fruit with a thickness of 5-6cm;

[0040] (2) After 2 days of stacking the camellia fruit, spray an ethephon solution with a concentration of 0.12% on the surface of the camellia fruit, and continue to stack for 4 days after spraying;

[0041] (3) Add composite sand to the frying machine. After heating the composite sand at 35-40℃, keep the temperature of the composite sand, add the camellia fruit and stir continuously for 10 hours. After cooling, send it to the peeling machine for peeling treatment. Get camellia seeds;

[0042] (4) Put the oil-tea camellia seeds into the osmotic treatment solution, treat them under a vacuum of 0.06-0.08kPa for 35 minutes, freeze-d...

Embodiment 3

[0048] A novel compound drying method for camellia oleifera fruit, including the following steps:

[0049] (1) Stack the picked fresh camellia oleifera fruit in the stacking room, and spread a layer of 3-4cm heat dissipation compound on the ground before stacking the camellia oleifera fruit; then stack the camellia oleifera fruit with a thickness of 5-6cm;

[0050] (2) After 2 days of stacking the camellia fruit, spray an ethephon solution with a concentration of 0.2% on the surface of the camellia fruit, and continue to stack for 4 days after spraying;

[0051] (3) Add composite sand to the frying machine. After heating the composite sand at 35-40°C, keep the temperature of the composite sand, add the camellia fruit and stir for 12 hours. After cooling, send it to the peeling machine for peeling treatment. Get camellia seeds;

[0052] (4) Put the oil-tea camellia seeds into the osmotic treatment solution, treat them under a vacuum of 0.06-0.08kPa for 30-40min, freeze-dry them at -30℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com