Human body personalized hip joint femoral stem prosthesis adopting lightweight design and manufacturing method thereof

A lightweight design and hip joint technology, which is applied to hip joints, prostheses, femoral heads, etc., can solve the problems of inability to meet the individual customization needs of patients, inability to fully adapt, and poor stability, so as to improve service life and avoid stress Shielding and stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

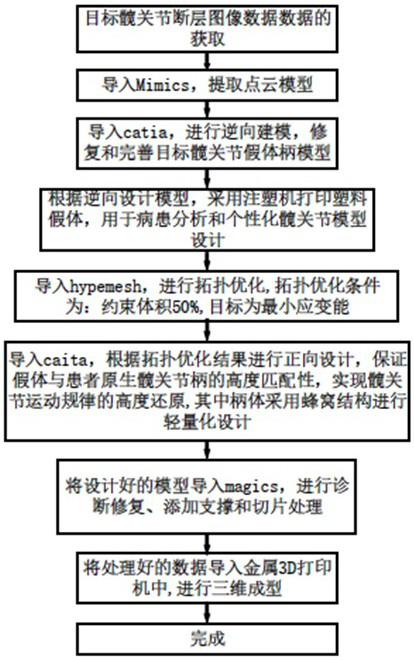

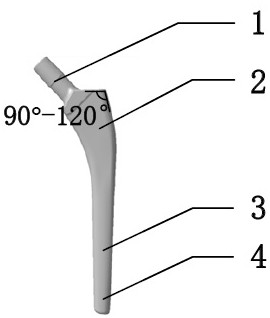

[0031] The human body personalized hip joint femoral stem prosthesis adopting lightweight design of the present invention and its manufacturing method include two main processes of extraction of individualized features of the physical model and forward design oriented by light weight, and the specific steps are: Use CT or MRI to scan the femoral stem of the patient's hip joint. After scanning, import the obtained tomographic image data into mimics to obtain the point cloud model of the hip joint stem, and complete subsequent reverse design, topology optimization and forward design based on the point cloud data. The design work is to complete the design of the personalized hip femoral stem prosthesis model, and the specific work is carried out in catia and hypemesh software; finally, the printing of the target hip f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com