A kind of ph value sensitive intelligent corrosion inhibitor and preparation method thereof

A sensitive and corrosion inhibitor technology, applied in the field of pH-sensitive core/shell nanostructure corrosion inhibitor and its preparation, can solve the problem of poor release controllability of corrosion-inhibiting components, narrow pH-sensitive range, and corrosion inhibitor failure. and other problems, to achieve the effect of enhancing the controllable release ability, wide pH sensitivity range, and good release controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

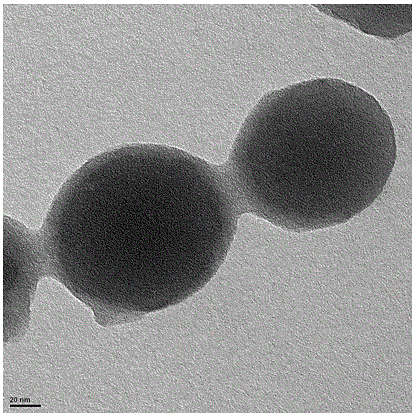

[0021] Dissolve 5 grams of sodium 2-acrylamide-2-methylpropanesulfonate in 1 liter of pure water, and then adjust the pH value of the solution to 8, and use a stirrer to vigorously stir the solution at a speed of 1500 rpm. The temperature of the solution was raised to 70°C, and then 7.5 grams of corrosion inhibitor sodium silicate and 30 grams of N-isopropylacrylamide were added under the condition of nitrogen gas, and 2 grams of sodium persulfate was added after continuous vigorous stirring for 2 hours, and the reaction was carried out for 20 hours After cooling to 15°C, add 5 ml of a polypropyleneimine aqueous solution with a concentration of 15 g / L, ultrasonically mix for 2 hours, and vacuum dry at 45° for 12 hours to obtain a shell composed of polypropyleneimine and polyacrylamide A pH-sensitive core / shell nanostructure corrosion inhibitor composed of propanesulfonic acid and poly(N-isopropylacrylamide) loaded with sodium silicate as a corrosion inhibitor component, which c...

Embodiment 2

[0028] Dissolve 3 grams of ammonium isethionate in 1 liter of pure water, and then adjust the pH value of the solution to 8, use a stirrer to vigorously stir the solution at a speed of 1500 rpm, and at the same time raise the temperature of the solution to 70 ° C, and then Add 6 grams of corrosion inhibitor cerium nitrate and 20 grams of D-lactic acid under the condition of nitrogen gas, continue to stir vigorously for 2 hours, add 0.5 grams of ammonium persulfate, cool to 15 °C after 20 hours of reaction, and then add 3 milliliters of 20 g / L polyphthalimide aqueous solution, ultrasonic mixing for 2 hours, vacuum drying at 45 ° for 12 hours, to obtain a shell composed of polyphthalimide and polyisethionic acid, The core is composed of poly-D-lactic acid loaded with cerium nitrate, a corrosion inhibitor, which is a pH-sensitive core / shell nanostructure corrosion inhibitor that can inhibit metal corrosion for a long time.

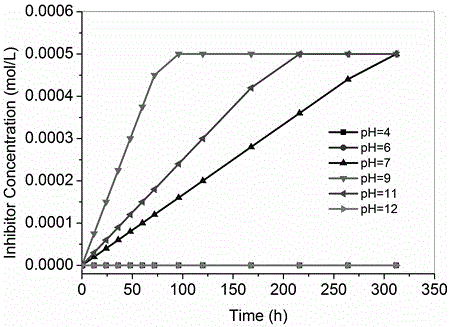

[0029]The characterization and test results of the corr...

Embodiment 3

[0031] Dissolve 4 grams of sodium 2-acrylamide-2-methylpropanesulfonate in 1 liter of pure water, and then adjust the pH value of the solution to 8, and use a stirrer to vigorously stir the solution at a speed of 1500 rpm. The temperature of the solution was raised to 70°C, and then 5 grams of corrosion inhibitor sodium molybdate and 20 grams of N-isopropylacrylamide were added under the condition of nitrogen gas, and 1 gram of sodium persulfate was added after continuous vigorous stirring for 2 hours, and the reaction was carried out for 20 hours After cooling to 15°C, 5 ml of polyphthalimide aqueous solution with a concentration of 10 g / L was added, ultrasonically mixed for 2 hours, and then vacuum-dried at 45° for 12 hours to obtain a shell made of polyphthalimide. Composed of imide and polyacrylamide methylpropane sulfonic acid, the core is composed of poly-N-isopropylacrylamide loaded with corrosion inhibitor sodium molybdate, a pH sensitive and long-lasting inhibitor of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com