High-strength airflow uniform distribution plate and desulfurizing tower

A high-strength technology with uniform airflow distribution plate, which can be used in gas treatment, use of liquid separation agents, membrane technology, etc., and can solve problems such as easy fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

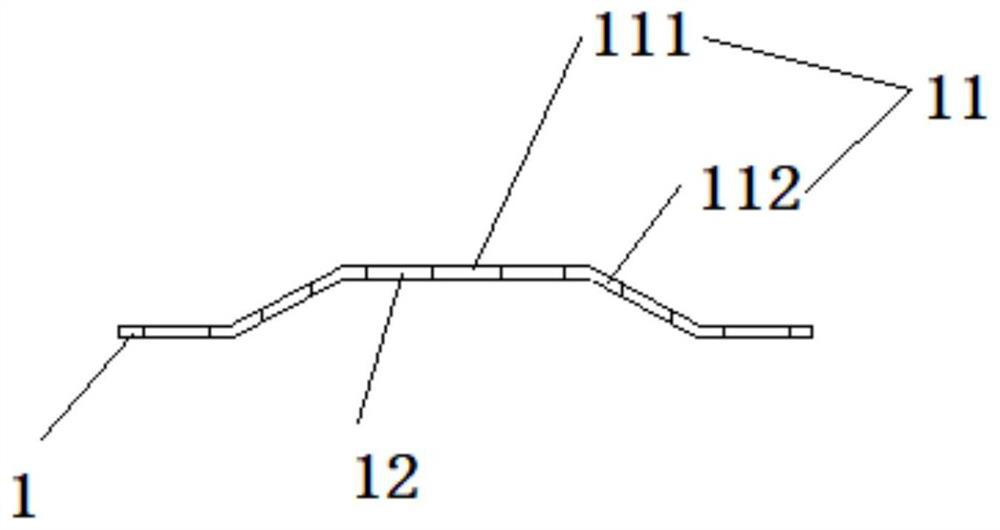

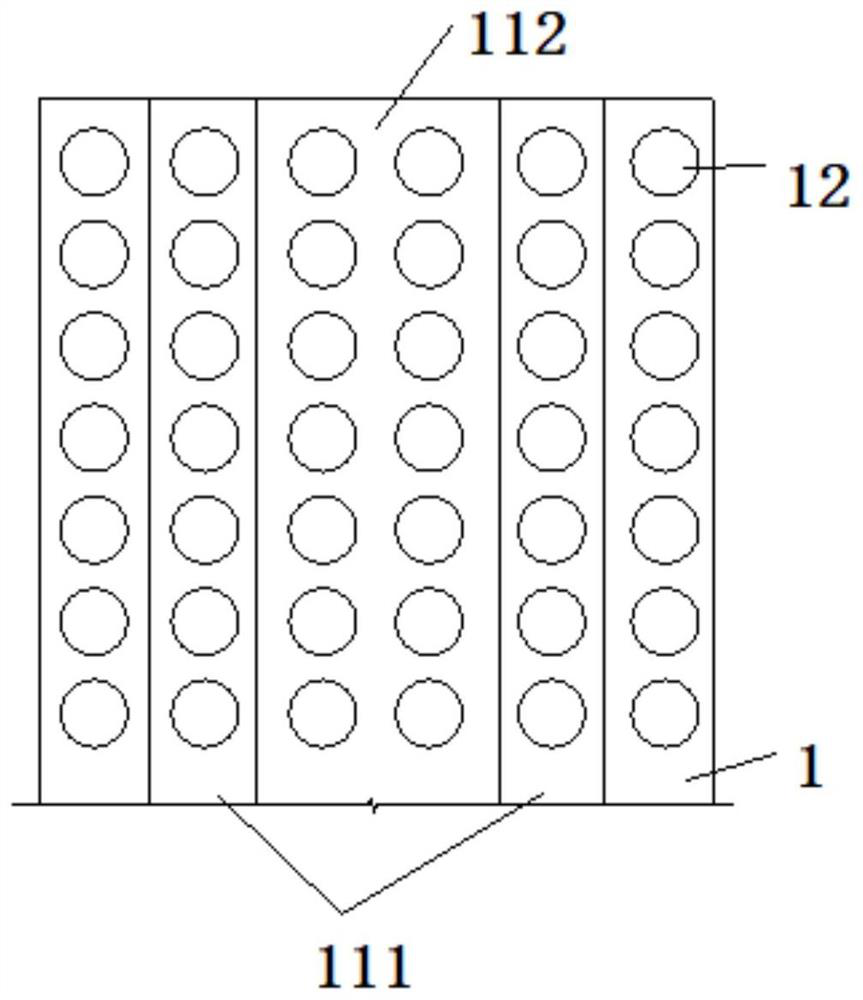

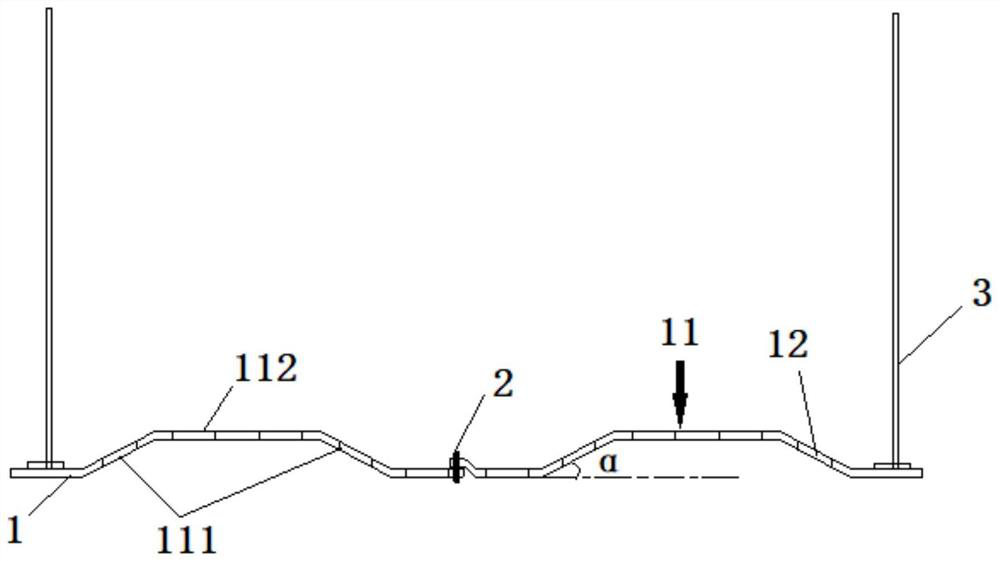

[0051] The invention provides a high-strength air distribution plate, such as figure 1 , figure 2 As shown, it includes: a base plate 1 provided with a number of ventilation holes 12 ; a reinforcement structure 11 provided on the base plate 1 and protruding outward relative to the base plate 1 . On the one hand, the outwardly protruding reinforcement structure 11 can improve the strength of the airflow uniform distribution plate itself, and can also increase the surface area of the airflow uniform distribution plate, increase the opening area, and improve the efficiency of smoke passing through. The air flow uniform distribution plate is usually below the wet dust removal mechanism 5, and performs flow equalization treatment on the flue gas before the flue gas is subjected to wet dust removal. The air flow uniform distribution plate with the reinforced structure 11, because the reinforced structure 11 protrudes relatively outward, the area receiving spray increases, and mo...

Embodiment 2

[0057] The present invention also provides a desulfurization tower, such as Figure 4 As shown, it includes: a wet dust removal mechanism 5, which is correspondingly arranged in the channel for flue gas flow in the desulfurization tower; The air flow uniform distribution plate with the reinforced structure 11, because the reinforced structure 11 protrudes relatively outward, the area receiving spray increases, and more spray liquid adheres to the air flow uniform distribution plate, which improves the spray liquid and smoke Air contact area and contact efficiency, thus enhancing the effect of wet dust removal.

[0058] On the basis of the above embodiments, as a further limited embodiment, such as Figure 4 As shown, the desulfurization tower also includes: a variable diameter section 4, which is located below the wet dust removal mechanism 5, and the cross-sectional area of the flue gas flow channel is within the scope of the variable diameter section 4. The direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com