Color-changing adsorption material capable of repeatedly and continuously adsorbing formaldehyde and preparation method thereof

An adsorption material and a technology for adsorbing formaldehyde, which are applied in the field of color-changing adsorption materials and their preparation, can solve the problem that the carrier of the adsorption material cannot be reused in the case of formaldehyde removal, and achieve the effect of rapid and efficient removal, large specific surface area, and obvious color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

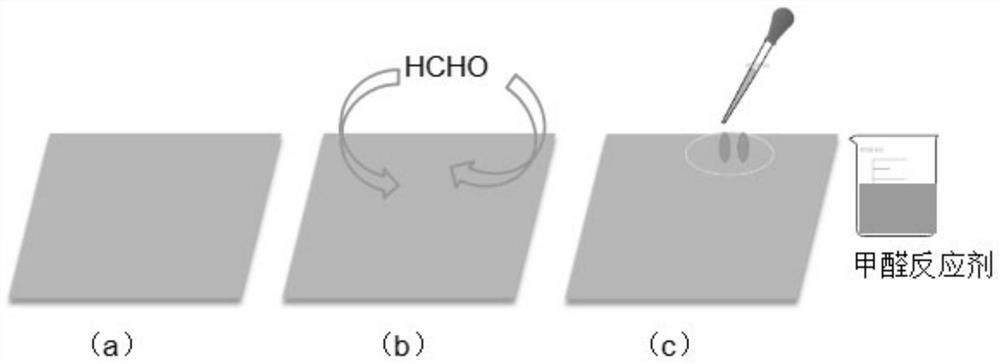

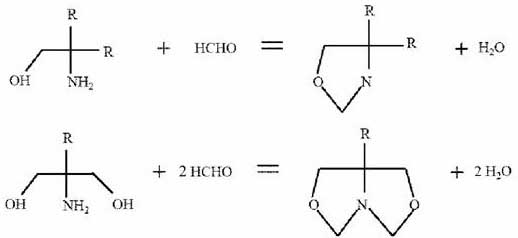

[0037] Dissolve 20 g of HOCH2C(NH2)(CH3)CH2OH in 100 ml of deionized water and stir evenly to make a formaldehyde reactant. The resulting solution is (a); add 3 mL of a single developer to solution (a) Xinghong, stir evenly to obtain solution (b); add 10g of magnesium chloride to solution (b), stir evenly to obtain solution (c), soak the spare white water-absorbing sponge in solution (c) in advance, and then vacuum Dry at 40°C in a drying oven to make a color-changing formaldehyde-removing sponge carrier.

[0038]After the reaction is complete, the color of the sponge changes from yellow to red; when the color turns red, it is perceived that the formaldehyde reactant has absorbed formaldehyde and undergoes a chemical reaction; spray the formaldehyde reactant again, and the color of the sponge carrier changes to the color of the unreacted sponge—yellow .

Embodiment 2

[0040] Dissolve 15 g of HOCH2CH(OH)CH2NH2 in 100 ml of deionized water and stir evenly to make a formaldehyde reactant. The resulting solution is (a); add 2 mL of mixed developer thymolphthalein to the solution (a)— Alizarin yellow, stir evenly to obtain solution (b); add 15g of magnesium chloride to solution (b), stir evenly to obtain solution (c), soak the spare white water-absorbing sponge in solution (c) in advance, and then Dry it in a vacuum oven at 40°C to make a color-changing formaldehyde-removing sponge carrier.

[0041] After the reaction is complete, the color of the sponge changes from purple to yellow; the formaldehyde reactant is sprayed again, and the color of the sponge carrier changes to the color of the unreacted sponge—purple.

Embodiment 3

[0043] 10 g HOCH 2 CH(NH 2 )CH 2 Dissolve OH in 100 ml of deionized water and stir evenly to make a formaldehyde reactant. The obtained solution is (a); add 5 mL of a single color developer neutral red to the solution (a), stir evenly to obtain the solution (b) Add 10g of magnesium chloride to the solution (b), stir evenly to obtain the solution (c), soak the spare white water-absorbing sponge in the solution (c) in advance, and then dry it in a vacuum oven at 40°C to prepare Into a color-changing formaldehyde removal sponge carrier.

[0044] After the reaction is complete, the color of the sponge changes from yellow to red; the formaldehyde reactant is sprayed again, and the color of the sponge carrier changes to the color of the unreacted sponge—yellow.

[0045] testing sample Formaldehyde removal rate after 24h Color changes Example 1 96.3 yellow → red Example 2 93.5 purple → yellow Example 3 92.4 yellow → red

[0046] The color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com