Method for compressing and densifying fast-growing cunninghamia lanceolata

A technology of densification and fir wood, which is applied in the direction of wood compression, wood treatment, impregnation of wood, etc., can solve the problems of easy deformation recovery, low compression rate, and low dimensional stability, and achieve dimensional stability, high compression rate, and relief of wood The effect of undersupply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

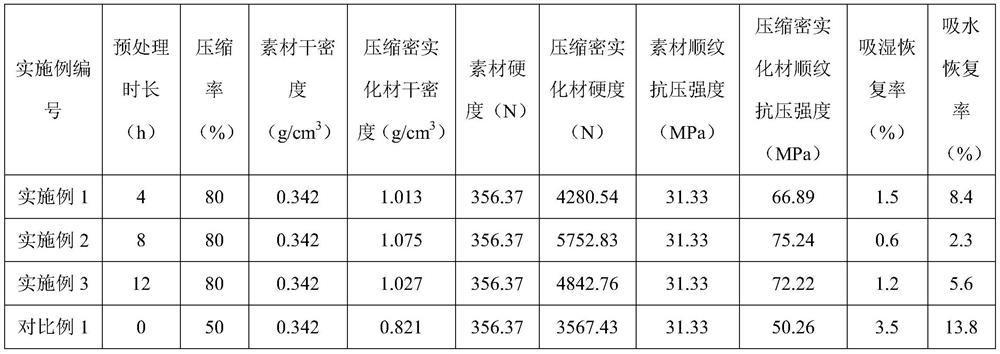

Embodiment 1

[0024] Present embodiment is an example of the method for fast-growing Chinese fir compression compaction of the present invention, comprises the following steps:

[0025] (1) processing of Chinese fir wood, processing the sapwood of Chinese fir wood into a wood block sample with a size of 20*20*20mm;

[0026] (2) Preparation of fir compression and densification pretreatment solution, configure a pretreatment solution of 2.5mol / L sodium hydroxide and 0.4mol / L sodium sulfite, stir evenly, and boil;

[0027] (3) Pretreatment of fir compression and densification, placing the fir block sample in a boiling pretreatment solution at 100°C for 4 hours, and then in boiling deionized water several times to remove chemical substances;

[0028] (4) balance the moisture content of the wood before pressing, and control the moisture content of 60% of the fir block sample after the pretreatment;

[0029] (5) Compression and densification of Chinese fir wood, place the wood block sample with ...

Embodiment 2

[0032] The present embodiment is another example of the method for fast-growing fir compression and compaction of the present invention, comprising the following steps:

[0033] (2) processing of Chinese fir wood, processing the sapwood of Chinese fir wood into a wood block sample with a size of 20*20*20mm;

[0034] (2) Preparation of fir compression and densification pretreatment solution, configure a pretreatment solution of 2.5mol / L sodium hydroxide and 0.4mol / L sodium sulfite, stir evenly, and boil;

[0035] (3) Pretreatment of fir compression and densification, place the fir block sample in a boiling pretreatment solution at 100°C for 8 hours, and then in boiling deionized water several times to remove chemical substances;

[0036] (4) balance the moisture content of the wood before pressing, and control the moisture content of 60% of the fir block sample after the pretreatment;

[0037] (5) Compression and densification of Chinese fir wood, place the wood block sample w...

Embodiment 3

[0040] Present embodiment is another example of the method for fast-growing Chinese fir compression and densification described in the present invention, comprises the following steps:

[0041] (3) processing of Chinese fir wood, processing the sapwood of Chinese fir wood into a wood block sample with a size of 20*20*20mm;

[0042] (2) Preparation of fir compression and densification pretreatment solution, configure a pretreatment solution of 2.5mol / L sodium hydroxide and 0.4mol / L sodium sulfite, stir evenly, and boil;

[0043] (3) Pretreatment of fir compression and densification, placing the fir block sample in a boiling pretreatment solution at 100°C for 12 hours, and then soaking it in boiling deionized water several times to remove chemical substances;

[0044] (4) balance the moisture content of the wood before pressing, and control the moisture content of 60% of the fir block sample after the pretreatment;

[0045](5) Compression and densification of Chinese fir wood, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com