Industrial wastewater filtering and clarifying device

A clarification device and industrial wastewater technology, applied in the direction of filtration circuit, filtration separation, filtration treatment, etc., can solve the problems of slowing down the speed, reducing the filtering effect of the fence, etc., achieving obvious effects and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

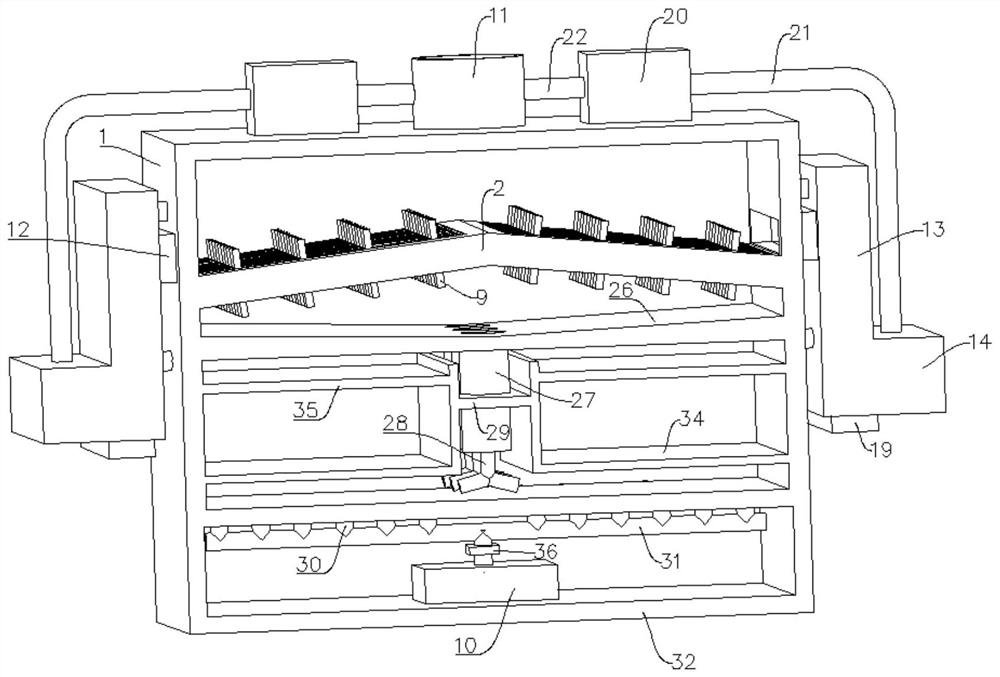

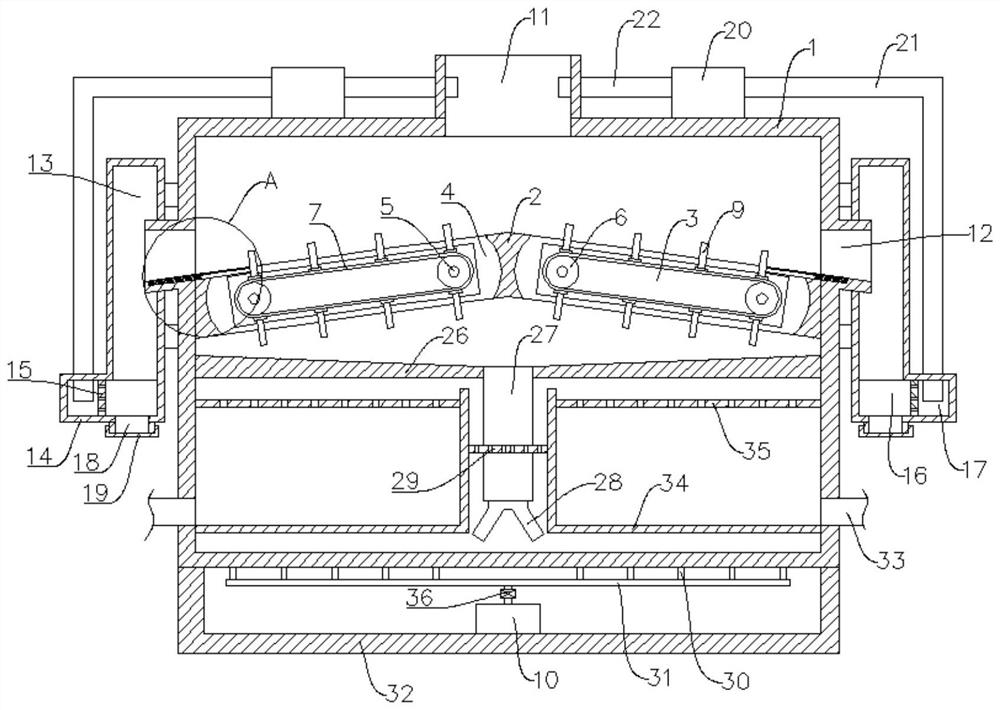

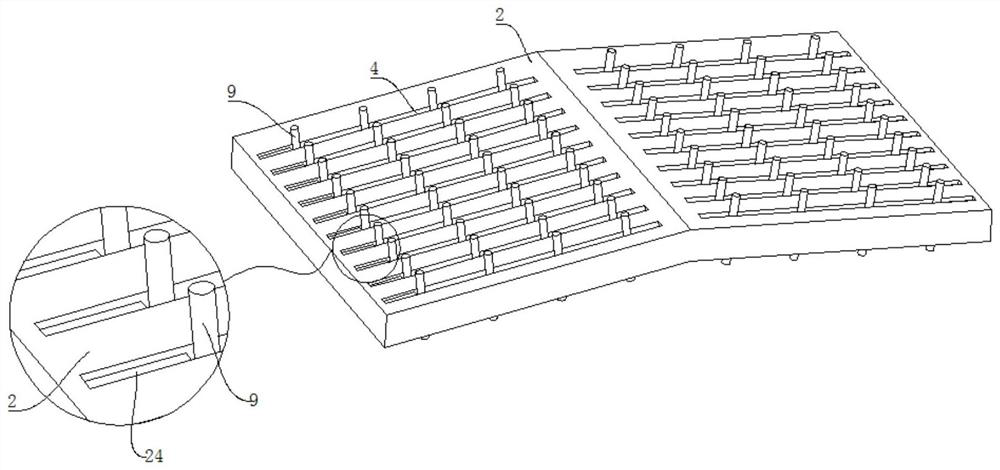

[0025] refer to Figure 1-8 , an industrial waste water filtration and clarification device, comprising a box body 1, the interior of the box body 1 is fixedly provided with a filter partition 2, the filter partition plate 2 divides the interior of the box body 1 into upper and lower parts, and the middle part of the filter partition plate 2 is convex and the two sides are slope-shaped, so that most of the solid waste on the filter partition 2 will roll to the two ends of the filter partition 2 under the action of its own gravity, and block the filter fence on the filter partition 2 The stagnation will be greatly reduced.

[0026] In the present invention, the interior of the filter partition 2 is provided with two square grooves 3 that are symmetrical about the center of the filter partition 2, and the side walls around the square groove 3 are provided with a plurality of equidistantly distributed through grooves 4 outward. 4 runs through the upper and lower sides of the fil...

Embodiment 2

[0030] In embodiment 1, the solid waste staying at both ends of the filter partition 2 will gradually accumulate and accumulate on the filter partition 2. If these solid wastes are not removed in time, when the solid waste accumulates too much, even if there is a toggle lever 9 Even if the waste is moved, the waste cannot be pushed to both ends of the filter partition 2. These solid wastes will gradually cover the through groove 4 and affect the filtering effect of the filter partition 2. Refer to figure 1 and 2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a sewage outlet 12 is provided on the side wall of the box body 1 corresponding to the two lowest ends of the filter partition 2, and the bottom of the sewage outlet 12 is downward Inclined and the same as the inclination angle of the filter partition 2, the sewage outlet 12 connects the inside and the outside of the box body 1, and the solid waste accumulated at both e...

Embodiment 3

[0032] In Embodiment 2, by setting the sewage outlet 12, solid waste can be discharged through the sewage outlet 12, but at this time part of the waste water will also be discharged through the sewage outlet 12. If the waste water discharged through the sewage outlet 12 is directly discharged, since there is no In the later stage of secondary treatment and tertiary treatment, the wastewater contains a large amount of other substances to be treated, which will seriously affect the environment. Refer to figure 1 and 2 As another preferred embodiment of the present invention, the difference from Embodiment 2 is that a collection box 13 is fixedly arranged on the outer wall of the box body 1 through a connecting rod, and the sewage outlet 12 extends through the collection box 13 to the inside of the collection box 13, The collection box 13 and the sewage outlet 12 are airtightly arranged, and the bottom end of the collection box 13 is fixedly provided with a separation box 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com