Integrated photovoltaic module packaging adhesive film

A photovoltaic module packaging and film technology, which is applied in photovoltaic power generation, semiconductor devices, adhesives, etc., can solve the problems of delamination of the backplane, decreased adhesion between white EVA and the backplane and glass, and high prices of inorganic fillers. Adhesion and reduction of the effect of the back sheet lamination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] above as figure 1 and 3 The preparation method of the integrated photovoltaic module encapsulation film includes the following steps:

[0037] 1. After fully mixing the resin and inorganic filler, co-extrude and granulate through a twin-screw extruder to make masterbatch;

[0038] 2. Put the masterbatch and resin into the mixer and mix them thoroughly for 5-10 minutes, put them into the extrusion hopper, cast them through a single screw or twin screws, and then squeeze them through a structured rubber roller and a smooth rubber roller on the surface, after cooling Get the structured reflective layer 1;

[0039] 3. Add the mixed resin, antioxidant, cross-linking agent, and silane coupling agent into the mixer and mix thoroughly for 5 to 15 minutes. Extrude and cast on the lower surface of the structured reflective layer 1 through a single screw, and Composite with the back plate 3 through rubber rollers;

[0040] 5. After trimming, winding, and packaging processes, a...

Embodiment 1

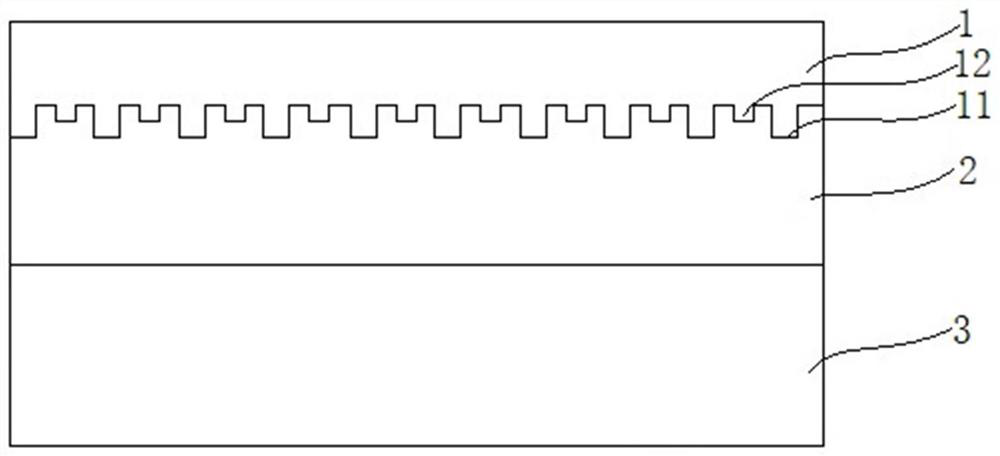

[0043] A kind of integrated photovoltaic module encapsulation adhesive film of the present invention, such as figure 1 As shown, the structured reflective layer 1, the transition layer 2 and the back plate 3 are arranged sequentially from top to bottom, the upper surface of the structured reflective layer 1 is a planar structure, the thickness of the structured reflective layer 1 is 50 μm, and the material of the structured reflective layer 1 is Inorganic filler and resin, the mass percentage of the inorganic filler is 30%, the mass percentage of the resin is 70%, the inorganic filler is mixed with titanium dioxide and lithopone; the resin is mixed with modified EVA resin and modified PO resin. The lower surface of the structured reflective layer 1 is periodically arranged by a plurality of raised cubes, the raised cubes have a plurality of first raised cubes 11 and a plurality of second raised cubes 12, the first raised cubes 11 and the second raised cubes Cubes 12 are arrang...

Embodiment 2

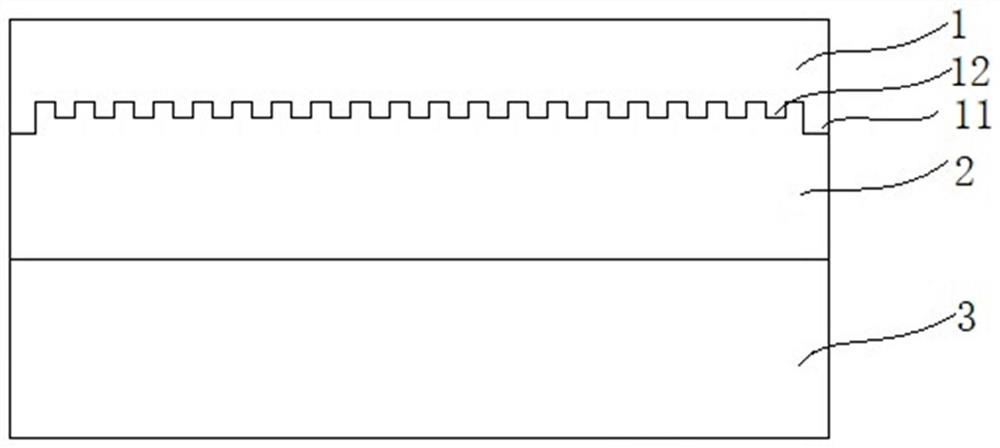

[0045] A kind of integrated photovoltaic module encapsulation adhesive film of the present invention, such as image 3 As shown, the structural reflection layer 1, the transition layer 2 and the back plate 3 are arranged sequentially from top to bottom, the upper surface of the structural reflection layer 1 is a planar structure, the thickness of the structural reflection layer 1 is 50 μm, and the material of the structural reflection layer 1 is Inorganic filler and resin, the mass percentage of the inorganic filler is 30%, the mass percentage of the resin is 70%, the inorganic filler is mixed with titanium dioxide and lithopone; the resin is mixed with modified EVA resin and modified PO resin. The lower surface of the structured reflective layer 1 has a plurality of first raised cubes 11 and a plurality of second raised cubes 12, the first raised cubes 11 are arranged on the edge of the lower surface of the structured reflective layer 1, and the second raised cubes 12 It is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com