Device and method for refining crude lignite wax

A technology of montan wax and coal wax, applied in the recovery/refining of mineral wax, petroleum industry, etc., can solve the problems of incomplete reaction between wax and oxidant, limited reaction of oxidant, oxidant oxidation ability needs to be improved, etc., to achieve non-toxic, The effect of reducing the amount of waste water discharge and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

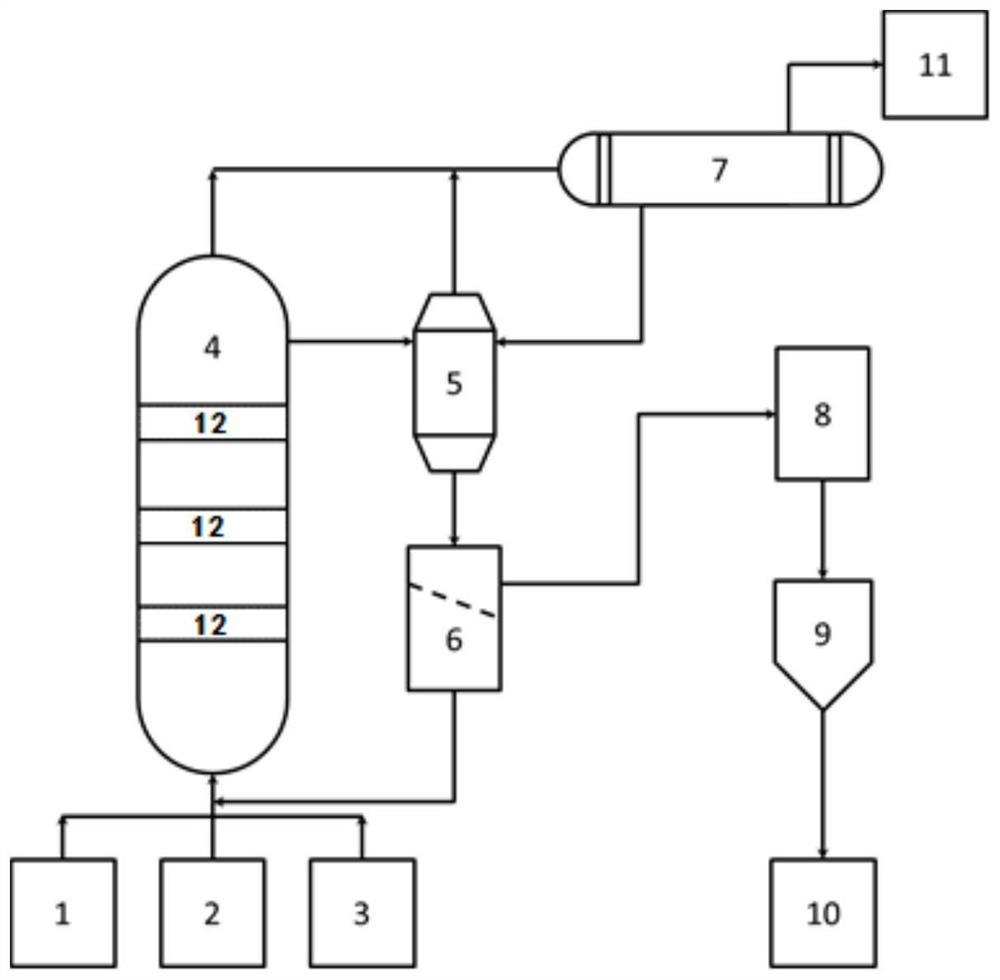

[0060] Take 2g of degreasing wax and put it in such as figure 1 In the refining reaction kettle shown, there are 10 layers of sand core plates, the distance between two adjacent layers of sand core plates is 5cm, and the material of the sand core plates is quartz; the aperture is 2μm; the thickness is 3mm. Add 6 mg of butanol as an auxiliary agent, and react with ozone for 60 minutes at 90°C, and the amount of ozone generated is 80 mg / h. As the reaction progresses, the degreasing wax gradually decolorizes, and passes through the sand core plate and gathers to the top of the kettle; the pooled and reacted refined wax overflows into the cooling tank, and the refined wax gradually solidifies into a solid; the flow in the cooling tank enters the filter The solid refined wax enters the drier after being washed with water for further drying; the liquid mother liquor returns to the refining reaction kettle and continues to be recycled as the reaction mother liquor; the dried solid wa...

Embodiment 2

[0063] Using the same reaction device and method as in Example 1, the only difference is that ozone was passed through at 100° C. for 60 minutes for reaction. The yield of the obtained refined wax is 75.3%, and the whiteness is 74.4%.

Embodiment 3

[0065] Using the same reaction device and method as in Example 1, the only difference is that ozone was passed through for 60 minutes at 80° C. for reaction. The resulting refined wax has a yield of 80.3% and a whiteness of 71.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com