A kind of vacuum micro-evaporation molybdenum plating method for diamond particles

A technology of diamond particles and evaporation plating, which is applied in the field of composite materials, can solve the problems of low thermal conductivity of diamond/copper and loose thermal interface bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

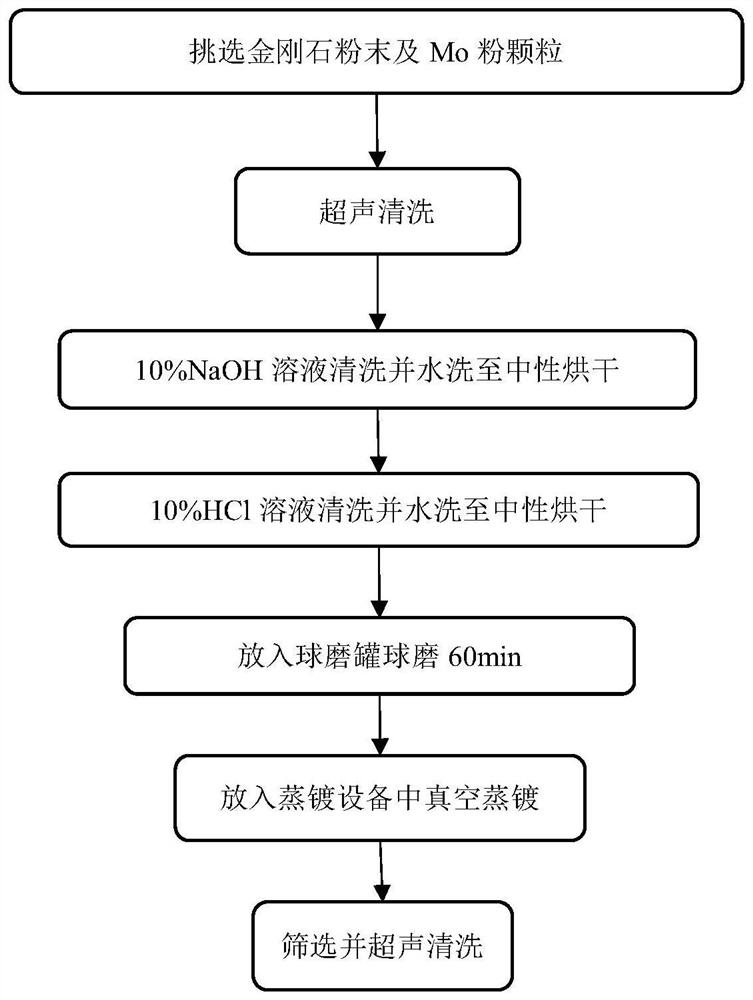

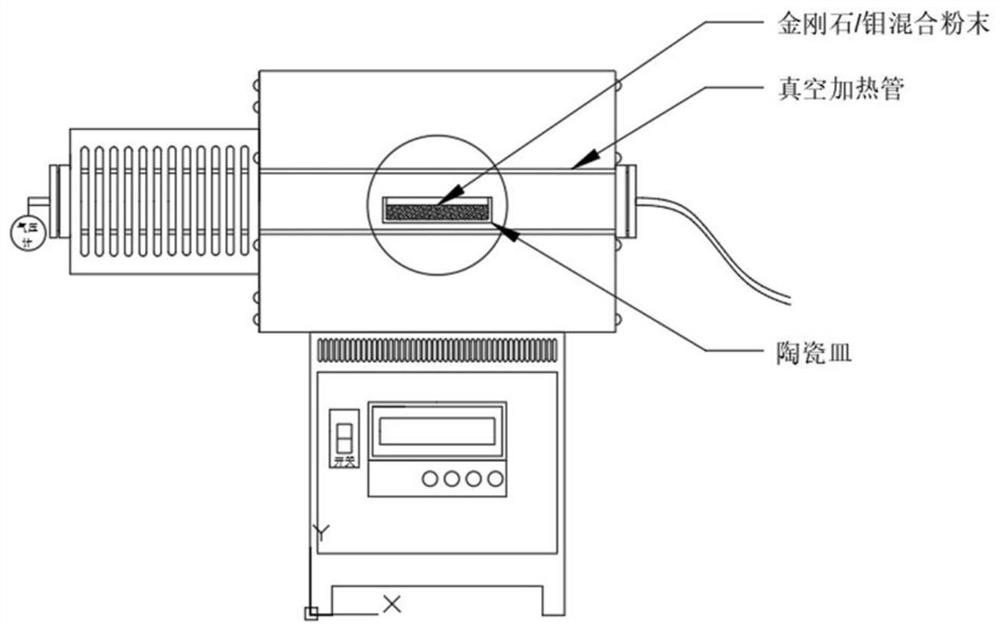

[0028] Such as Figure 1~3 Shown, the concrete steps of vacuum microevaporation diamond Mo coating method among the present invention are:

[0029] Step 1: Select Mo powder particles, diamond powder particles, the particle size of the Mo powder particles is 2 μm; the particle size of the diamond particles is 50-200 μm; and weigh 10 g of diamond and 8 g of Mo powder.

[0030] Step 2: cleaning the diamond particles;

[0031] Specific cleaning steps: first put the diamond in an acetone solution, and clean it with ultrasonic vibration for 5-10 minutes. Acetone as an organic solvent can effectively remove the hydrocarbons attach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com