Water recovery pipe column and water recovery method for water source well cable-laying nonmetal coiled tubing

A non-metal, water source well technology, applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of fragile cables, easily damaged external cables, poor water extraction effect, etc., and achieves fewer joints. , The effect of solving the problem of cable wear and reducing the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

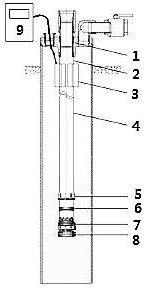

[0022] In order to overcome the problem that the existing cable is fragile and the whole water harvesting effect is poor, the present invention provides such figure 1 and figure 2 Shown is a non-metallic coiled tubing water production string and water production method for a water source well. The present invention is a method in which the cable is directly built into the coiled tube body, the cable is effectively protected, and the external cable is easily damaged. shortcoming. At the same time, the cables laid in the pipe body can provide power for downhole submersible pumps and other equipment, collect downhole data for real-time transmission and monitoring, etc., effectively reducing the chance of submersible pumps and other equipment being burned due to cable damage, and avoiding workover and other operations.

[0023] A cabled non-metallic coiled tubing string for water source wells, comprising a standard wellhead 1, a ground control system 9 located outside the standa...

Embodiment 2

[0029] On the basis of Embodiment 1, in this embodiment, preferably, the short joint 2 of the oil pipe is connected to the non-metallic coiled oil tubing 4 through the conversion joint 3 .

[0030] Preferably, a cable connector is reserved at the upper end of the cable-laying non-metallic coiled tubing 4 , and the cable connector is electrically connected to the ground control system 9 .

[0031] Preferably, the lower end of the cable-laying non-metallic coiled tubing 4 is connected to the liquid level monitoring device 5 through a conversion joint 3 .

[0032] Preferably, the cable-clad non-metallic coiled tubing 4 is a coiled tubing in which cables are armored in the tube body.

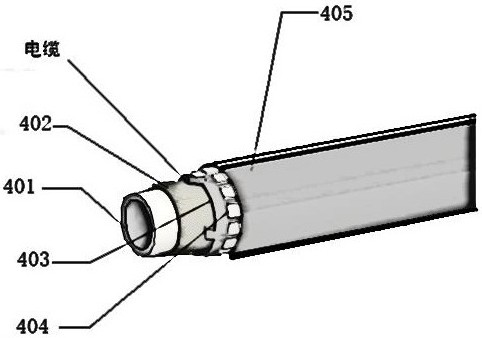

[0033] like figure 2 As shown, the cabled non-metallic coiled tubing 4 includes a pipe core 401 and a reinforcement layer 402 , a tensile layer 404 and an outer protective layer 405 that are sheathed outside the pipe core 401 in sequence. The cable armor is between the reinforcement layer 402 and...

Embodiment 3

[0040] Based on Embodiment 1 or 2, this embodiment provides a method for producing water by cable-coated non-metallic coiled tubing in a water source well. The wellbore and the downhole tubing string are partly submerged below the liquid level; after the tubing string is put in place, the standard wellhead 1 is installed, the cable is connected to the ground control system 9, and the downhole water source well liquid level monitoring device 5 is collected by laying non-metallic coiled tubing 4 Data, real-time monitoring of the current and voltage working parameters of the submersible pump 7 and the motor 8, recording the water production of the water source well, and at the same time realizing the on-site start and stop of the water source well.

[0041] The part of the downhole pipe string submerged below the liquid surface is to place the motor 8 above 3 meters away from the bottom of the well, and the submersible pump 7 is submerged at least 1 meter below the dynamic water l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com