Activated carbon filter element and preparation method thereof

A technology of activated carbon filter element and activated carbon particles, applied in the field of filter element, can solve the problems of affecting the filtering effect, the number of flow channels, workshop pollution, etc., and achieve the effects of controllable molding process, improved filtering efficiency, and no pollution to the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

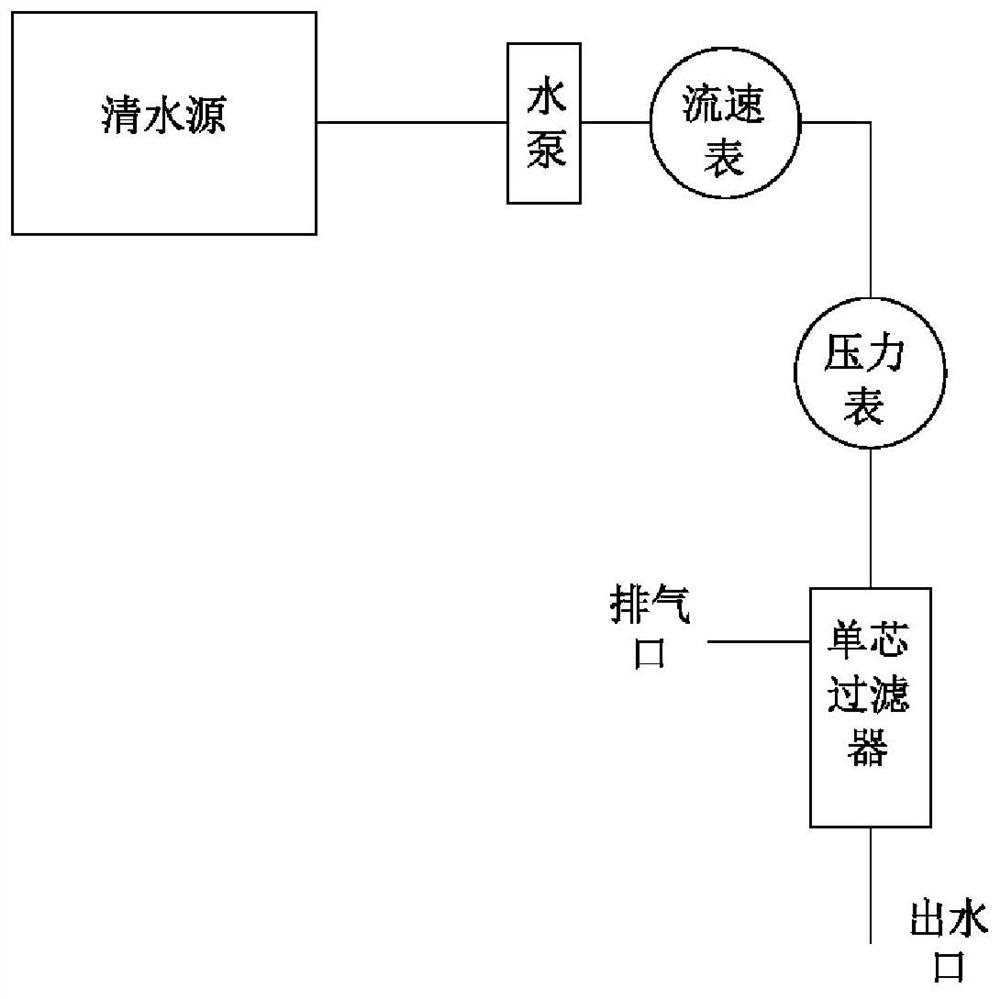

Embodiment 1

[0048] An activated carbon filter element includes a center rod and a filter layer arranged outside the center rod. The filter layer includes a supporting fiber network formed by fibrillated cellulose fibers, a bonding fiber network formed by urea fibers, and a shell polymer Sugar fibers are used as raw materials to form an adsorption fiber web and activated carbon particles distributed in the middle of the fiber web. A PP non-woven fabric is wrapped on the outside of the center rod, and a PE and PET composite non-woven fabric is wrapped on the outside of the filter layer. In order to prevent the filter element from falling off the filter layer and entering the filtrate under the working condition of higher pressure and flow rate, it will affect the filtration effect. At the same time, it can also facilitate the transportation and storage of the filter element. For the filter layer, the interior has a gradient three-dimensional space structure. The position near the inner layer...

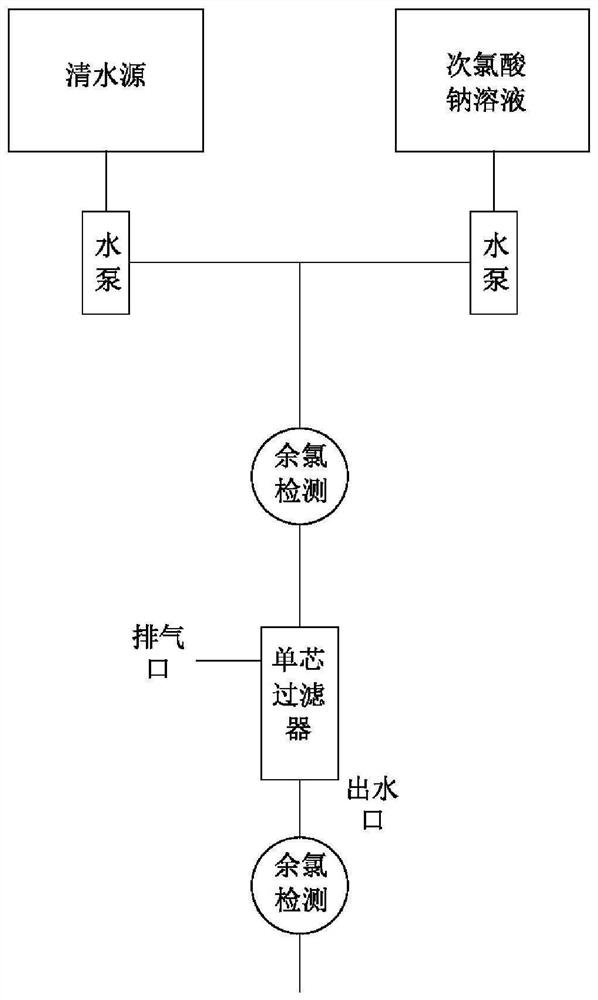

Embodiment 2

[0085] An activated carbon filter element includes a center rod and a filter layer arranged outside the center rod. The filter layer includes a supporting fiber network formed by fibrillated cellulose fibers, a bonding fiber network formed by urea fibers, and a shell polymer Sugar fibers are used as raw materials to form an adsorption fiber web and activated carbon particles distributed in the middle of the fiber web. A PP non-woven fabric is wrapped on the outside of the center rod, and a PE and PET composite non-woven fabric is wrapped on the outside of the filter layer. In order to prevent the filter element from falling off the filter layer and entering the filtrate under the working condition of higher pressure and flow rate, it will affect the filtration effect. At the same time, it can also facilitate the transportation and storage of the filter element. For the filter layer, the interior has a gradient three-dimensional space structure. The position near the inner layer...

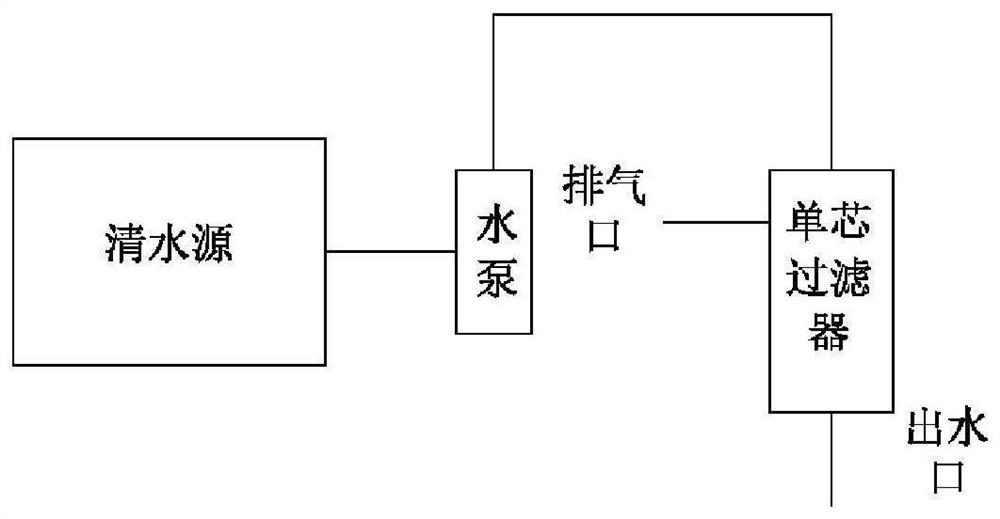

Embodiment 3

[0101] An activated carbon filter element includes a center rod and a filter layer arranged outside the center rod. The filter layer includes a supporting fiber network formed by fibrillated cellulose fibers, a bonding fiber network formed by urea fibers, and a shell polymer Sugar fibers are used as raw materials to form an adsorption fiber web and activated carbon particles distributed in the middle of the fiber web. A PP non-woven fabric is wrapped on the outside of the center rod, and a PE and PET composite non-woven fabric is wrapped on the outside of the filter layer. In order to prevent the filter element from falling off the filter layer and entering the filtrate under the working condition of higher pressure and flow rate, it will affect the filtration effect. At the same time, it can also facilitate the transportation and storage of the filter element. For the filter layer, the interior has a gradient three-dimensional space structure. The position near the inner layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com