Activated carbon filter element and preparation method thereof

A technology of activated carbon filter element and activated carbon particles, which is applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of affecting the filtration effect, less number of flow channels, dust emission, etc., so as to achieve controllable molding process and improve filtration efficiency. , the effect of controllable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

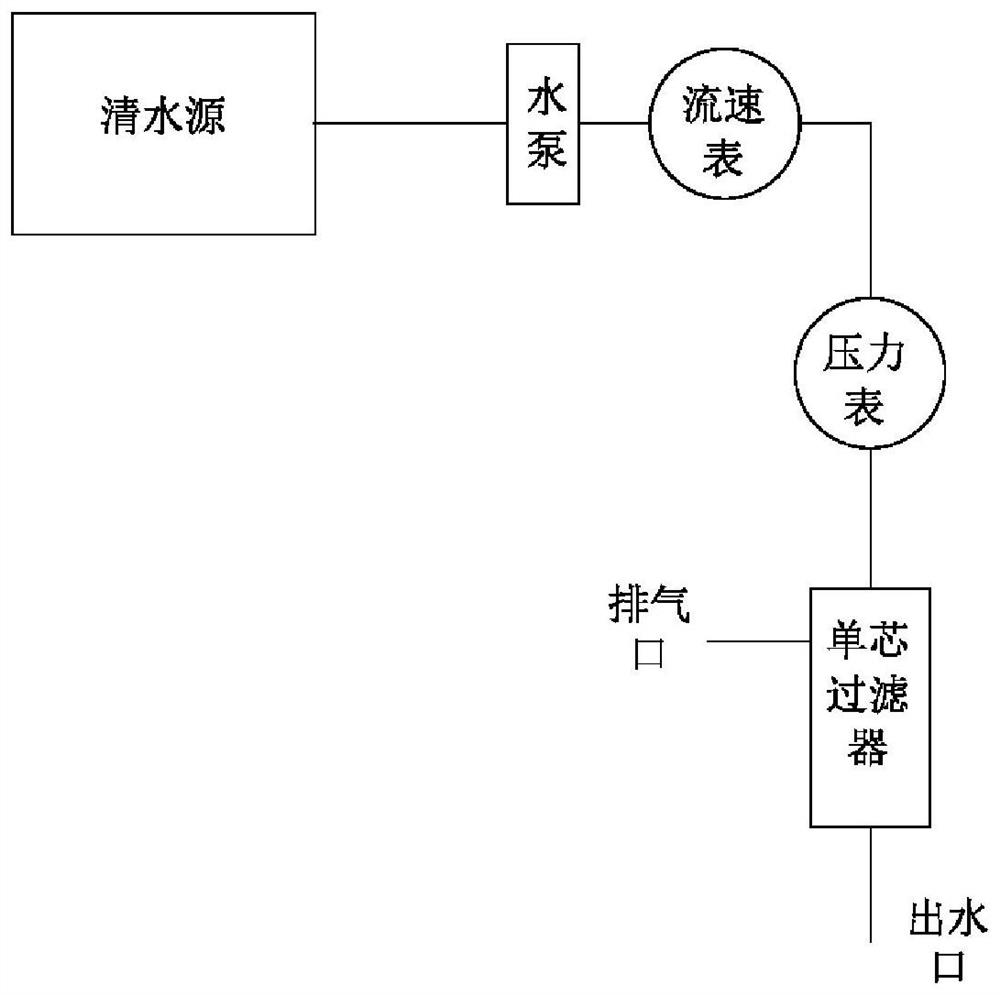

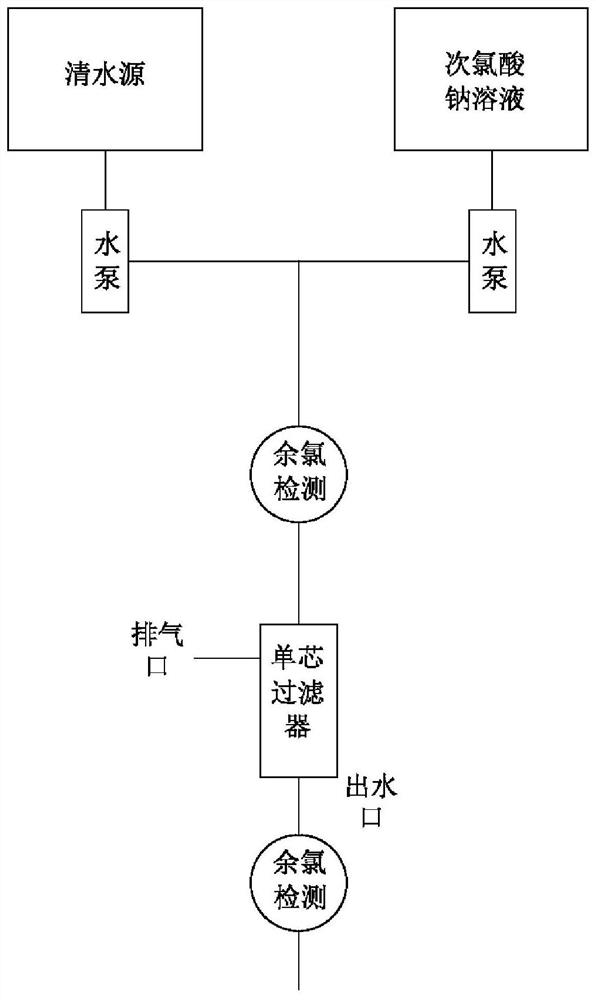

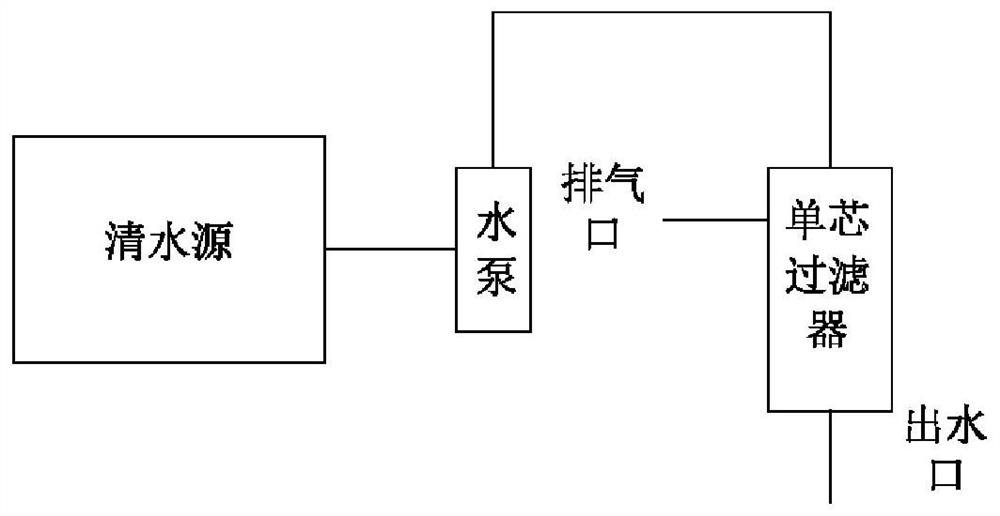

[0049] An activated carbon filter element, comprising a central rod and a filter layer arranged outside the central rod, the filter layer includes a support fiber web formed by fibrillated cellulose fibers, a bonded fiber web formed by urea fibers, and shell polymer The sugar fiber is an adsorption fiber web formed by raw materials and activated carbon particles distributed in the middle of the fiber web. The outside of the center rod is wrapped with PP non-woven fabric, and the outside of the filter layer is wrapped with PE and PET composite non-woven fabric. In order to prevent the filter element from falling off from the filter layer and entering the filtrate to affect the filtration effect under the condition of high pressure and flow rate of the filter element, it is also convenient for the filter element to be transported and stored. The surface is relatively clean and the activated carbon particles will not fall off. For the filter layer, it has a gradient three-dimensi...

Embodiment 2

[0092] An activated carbon filter element, comprising a central rod and a filter layer arranged outside the central rod, the filter layer includes a support fiber web formed by fibrillated cellulose fibers, a bonded fiber web formed by urea fibers, and shell polymer The sugar fiber is an adsorption fiber web formed by raw materials and activated carbon particles distributed in the middle of the fiber web. The outside of the center rod is wrapped with PP non-woven fabric, and the outside of the filter layer is wrapped with PE and PET composite non-woven fabric. In order to prevent the filter element from falling off from the filter layer and entering the filtrate to affect the filtration effect under the condition of high pressure and flow rate of the filter element, it is also convenient for the filter element to be transported and stored. The surface is relatively clean and the activated carbon particles will not fall off. For the filter layer, it has a gradient three-dimensi...

Embodiment 3

[0113] An activated carbon filter element, comprising a central rod and a filter layer arranged outside the central rod, the filter layer includes a support fiber web formed by fibrillated cellulose fibers, a bonded fiber web formed by urea fibers, and shell polymer The sugar fiber is an adsorption fiber web formed by raw materials and activated carbon particles distributed in the middle of the fiber web. The outside of the center rod is wrapped with PP non-woven fabric, and the outside of the filter layer is wrapped with PE and PET composite non-woven fabric. In order to prevent the filter element from falling off from the filter layer and entering the filtrate to affect the filtration effect under the condition of high pressure and flow rate of the filter element, it is also convenient for the filter element to be transported and stored. The surface is relatively clean and the activated carbon particles will not fall off. For the filter layer, it has a gradient three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com