Plastic particle production system equipment for reinforcing composite plastic material

A technology of plastic materials and plastic particles, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of prolonged contact path time between gas and filtered liquid, single filter structure, and increased filter costs, etc., to achieve Improve the contact range and area, prolong the contact time, prolong the effect of contact distance and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

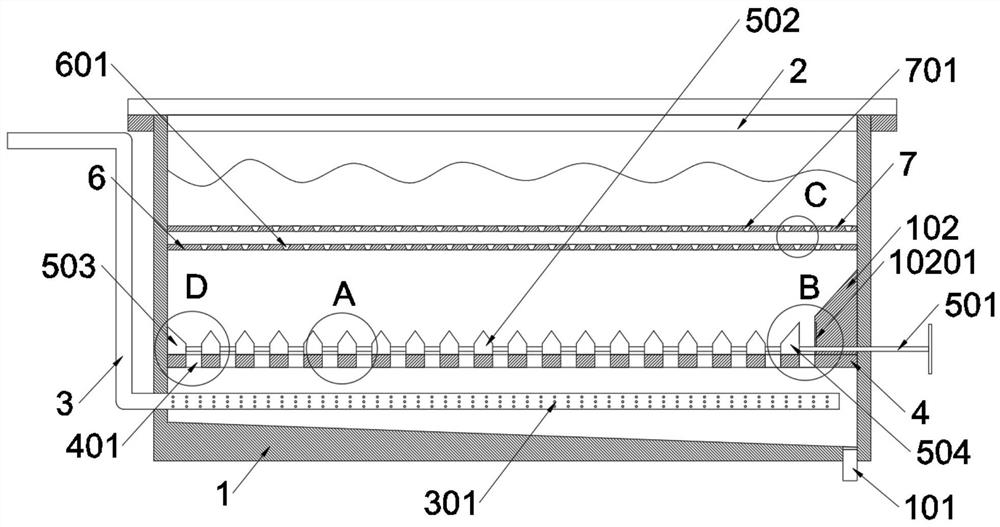

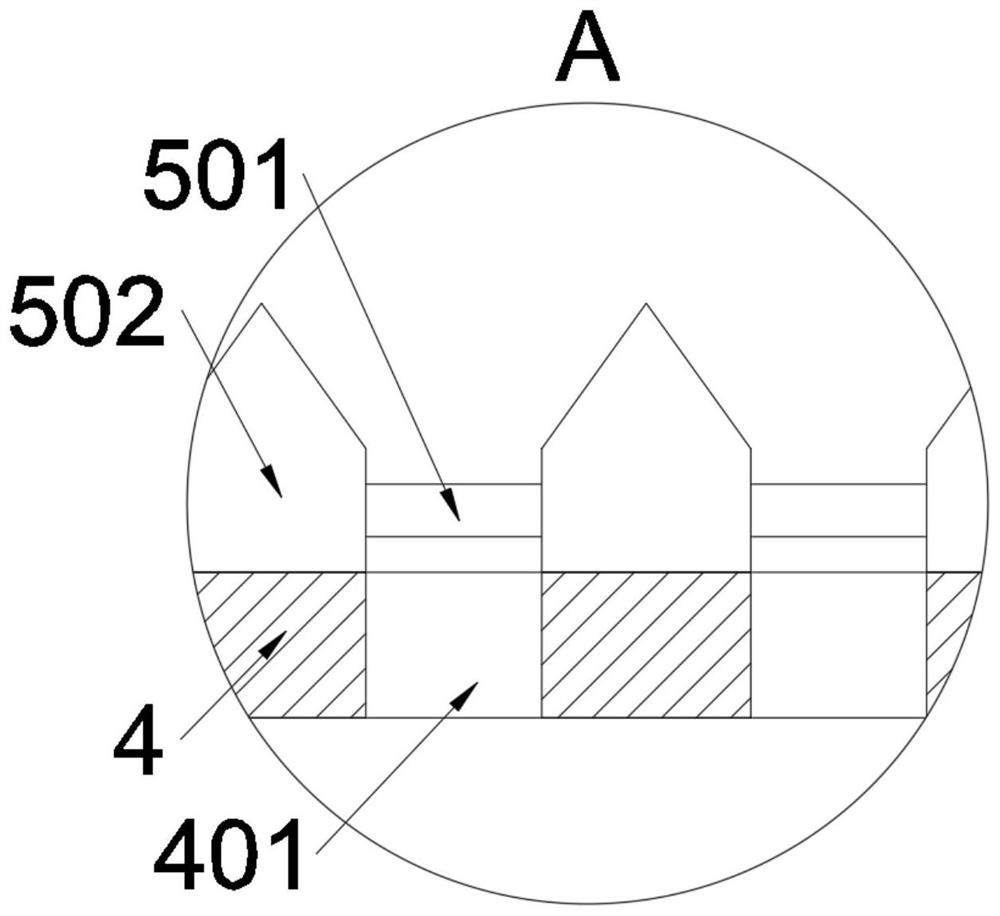

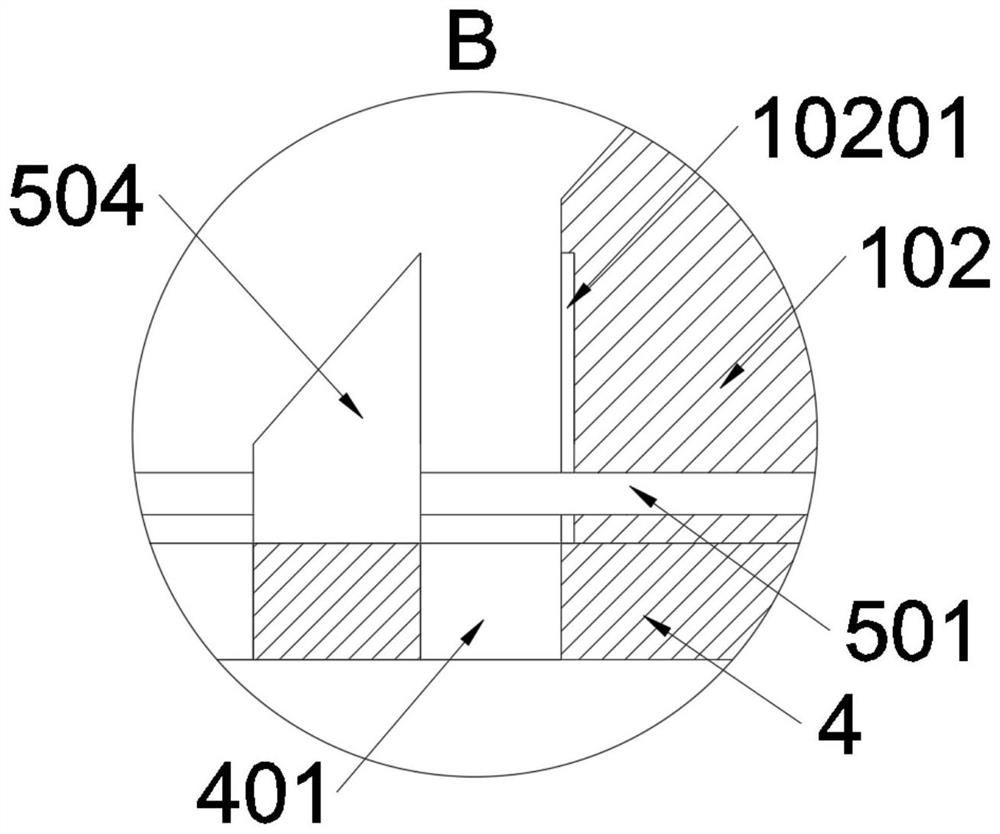

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a plastic particle production system equipment for reinforced composite plastic materials, including a filter box 1; the filter box 1 is a rectangular box-shaped structure, and the filter box 1 is fastened with a cover plate 2, and the filter box 1 An air intake pipe 3 is also connected to it; a partition 4 is fixedly connected to the filter box 1, and a closed structure 5 is also installed in the filter box 1; a filter plate A6 is installed on the filter box 1, and the filter box There is also a filter plate B7 installed in 1; refer to figure 1 figure 2 Figure 6 and Figure 7 , the closed structure 5 includes a sliding rod 501, a sealing block A502, a sealing block B503 and a sealing block C504, the sliding rod 501 is a cylindrical rod-shaped structure, and the sliding rod 501 is sealed and slidably connected to the filter box 1; the sliding rod 501 is welded with Sealing block A502...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com